Title: Custom CNC Machining Services in Lanzhou - The Ultimate Solution for Metal Fabrication

Lanzhou, the capital city of Gansu Province in China, is a hub for custom CNC machining services. These services are designed to meet the needs of industries and businesses that require precision metal fabrication. With state-of-the-art equipment and skilled technicians, companies can rely on these services to produce high-quality components and products.Custom CNC machining allows for precise cutting and shaping of metals, which makes it ideal for applications such as aerospace, automotive, medical, and consumer goods. The process involves programming the machine to create complex designs and shapes, which are then cut into the desired material with extreme accuracy. This results in faster production times and higher quality parts compared to traditional manufacturing methods.Lanzhou offers a range of custom CNC machining services, including milling, turning, drilling, and grinding. Companies can choose from a variety of materials, including aluminum, steel, and stainless steel. The machines used are also customizable based on the project requirements.Whether you are in need of small batch production or large-scale manufacturing, Lanzhou has the expertise to provide you with the ultimate solution for custom CNC machining services. Contact us today to learn more about how we can help your business succeed!

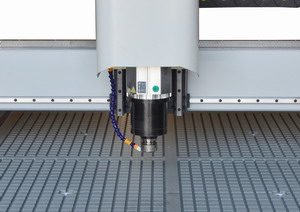

In the world of industrial manufacturing, precision and accuracy are crucial elements that determine the success of any project. CNC (Computer Numerical Control) machining is a process that has revolutionized the metal fabrication industry by providing high-precision, efficient, and cost-effective solutions. In Lanzhou, China, you can find some of the best CNC machining services that cater to various industries, including but not limited to automotive, aerospace, medical, and consumer goods. This article will explore the concept of CNC machining, its applications, and the benefits of working with a professional CNC machining company in Lanzhou.

What is CNC Machining?

CNC machining, short for Computer Numerical Control Machining, is a subtractive manufacturing technique that uses computerized software to control the movement of cutting tools such as mills, lathes, and routers. The process involves creating complex shapes and designs from metal, wood, or other materials by removing material from the workpiece. The software dictates the precise coordinates of the tool movements, ensuring consistency and accuracy throughout the machining process.

Applications of CNC Machining

CNC machining has numerous applications in different industries, each suited to specific needs and requirements. Some popular applications include:

1、Aerospace Industry: CNC machining is used in the aerospace industry to manufacture components for aircraft engines, missiles, satellites, and other critical components that require extreme precision and durability. The process allows for quick and efficient production of high-quality parts that meet stringent industry standards.

2、Automotive Industry: In the automotive industry, CNC machining is used to manufacture components such as engine blocks, transmission gears, and body parts. The process offers greater flexibility and faster production times compared to traditional manufacturing techniques, enabling manufacturers to respond quickly to changing market demands.

3、Medical Industry: CNC machining is used in the medical industry to manufacture surgical instruments, dental implants, and prosthetics. The process allows for accurate and customized production of high-precision components that meet the unique needs of patients.

4、Consumer Goods Industry: In the consumer goods industry, CNC machining is used to manufacture a wide range of products, including toys, jewelry, and household appliances. The process offers greater design freedom and faster production times, enabling manufacturers to quickly bring new products to market.

Benefits of Working with a Professional CNC Machining Company in Lanzhou

Working with a professional CNC machining company in Lanzhou offers several benefits, including:

1、High-Quality Production: Professional CNC machining companies in Lanzhou have state-of-the-art machinery and experienced technicians who ensure high-quality production of parts or products. They follow strict quality control measures to guarantee consistent performance and accuracy.

2、Faster Production Times: CNC machining allows for faster production times compared to traditional manufacturing techniques. The process enables manufacturers to produce large quantities of parts in a shorter time frame, reducing lead times and increasing profitability.

3、Cost-Effective Solutions: CNC machining is an cost-effective solution for small and large manufacturers alike. It eliminates the need for expensive tooling costs and labor fees associated with traditional manufacturing methods, allowing manufacturers to save on production costs without compromising quality.

4、Increased Design Flexibility: With CNC machining, designers can create complex geometries and intricate designs that are not possible using traditional manufacturing techniques. This increased design flexibility enables manufacturers to create unique products that stand out in the market.

5、Environmental Sustainability: CNC machining offers a more environmentally sustainable solution compared to traditional manufacturing techniques. It consumes less energy and produces fewer waste materials, contributing to a greener and more sustainable industrial ecosystem.

Conclusion

In conclusion, CNC machining is a powerful manufacturing technology that has transformed the metal fabrication industry in Lanzhou and beyond. By working with a professional CNC machining company, manufacturers can achieve high-quality production rates, faster turnaround times, cost savings, increased design flexibility, and environmental sustainability. As industries continue to evolve and demand more precision and efficiency in their manufacturing processes, CNC machining will undoubtedly continue to play a crucial role in shaping the future of industrial manufacturing.

Articles related to the knowledge points of this article:

Title: Crafting Elegant and Functional Hardware Solutions for Datong Home Customization

Custom Hardware in the Light of the Sun