Spring Hardware Fittings: Types, Applications, and Benefits

This article provides a comprehensive overview of spring hardware fittings, including their types, applications, and benefits. Spring hardware fittings are metal or plastic components that are used to connect or attach various objects together. They are commonly used in mechanical, electrical, and plumbing systems. The article discusses the different types of spring hardware fittings, such as compression springs, extension springs, and torsion springs. It also explains the various applications of spring hardware fittings, including their use in automotive, aerospace, and medical fields. Additionally, the article highlights the benefits of using spring hardware fittings, including their durability, versatility, and ease of installation.

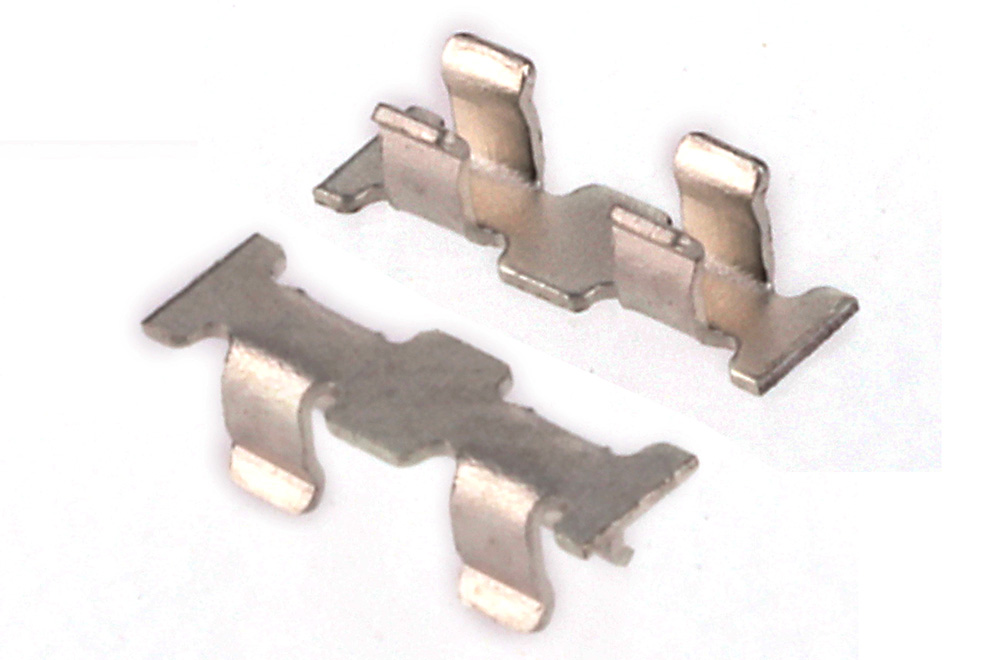

Spring hardware fittings are essential components in various mechanical systems. These fittings, made from metal alloys, provide a crucial connection between different parts of the system, allowing for smooth and efficient operation. In this article, we will explore the types, applications, and benefits of spring hardware fittings.

Types of Spring Hardware Fittings

There are several types of spring hardware fittings, each designed to meet specific mechanical requirements. Common types include:

1、Hook-type fittings: These fittings have a hook-like shape that allows them to engage with other parts of the system. They are commonly used in tension springs, where they provide a secure attachment point for the spring to other components.

2、Loop-type fittings: These fittings have a circular or oval shape that allows them to fit over other parts of the system. Loop-type fittings are commonly used in compression springs, where they engage with the spring to provide stability and support.

3、Barrel-type fittings: These fittings have a cylindrical shape that allows them to slide over other parts of the system. Barrel-type fittings are commonly used in torsion springs, where they engage with the spring to transmit torque.

4、Weld-on fittings: These fittings are designed to be welded directly onto other parts of the system. Weld-on fittings are commonly used in situations where a strong and permanent connection is required.

Applications of Spring Hardware Fittings

Spring hardware fittings have a wide range of applications in various mechanical systems. Some common applications include:

1、Automotive industry: Spring hardware fittings are commonly used in automotive suspension systems, where they provide a connection between the chassis and the wheels. These fittings help to absorb road vibrations and provide a smooth ride.

2、Aerospace industry: Spring hardware fittings are used in aircraft and spacecraft to provide structural support and absorb vibrations. These fittings help to ensure the stability and reliability of the aerospace systems.

3、Industrial machinery: Spring hardware fittings are commonly used in industrial machines to provide connections between moving parts and stationary components. These fittings help to transmit force and absorb vibrations, reducing wear and tear on the machinery.

4、Sports equipment: Spring hardware fittings are used in sports equipment such as tennis rackets, golf clubs, and basketball hoops to provide elasticity and absorb vibrations. These fittings help to enhance performance and reduce player fatigue.

Benefits of Spring Hardware Fittings

Spring hardware fittings provide a number of benefits to mechanical systems:

1、Smooth operation: By providing a connection between different parts of the system, spring hardware fittings allow for smooth and efficient operation. The elasticity of the springs allows for movement within a certain range, reducing friction and wear on the system.

2、Vibration absorption: Spring hardware fittings help to absorb vibrations in the system, reducing noise and improving the overall performance of the equipment. This is particularly important in high-precision applications where vibration can affect accuracy and reliability.

3、Structural support: Spring hardware fittings provide structural support to the system, helping to maintain its integrity and preventing damage due to excessive force or strain.

4、Thermal management: In some cases, spring hardware fittings can also serve as thermal management devices, helping to dissipate heat from critical components or regulate temperature within the system.

Conclusion

Spring hardware fittings are essential components in various mechanical systems, providing a crucial connection between different parts of the system while offering benefits such as smooth operation, vibration absorption, structural support, and thermal management. By understanding the types, applications, and benefits of spring hardware fittings, designers and engineers can better incorporate these components into their systems to achieve optimal performance and reliability.

Articles related to the knowledge points of this article:

Plastic and Metal Hardware Components: The Ultimate Guide

Title: Understanding the Cost of Kunshan Bag Hardware Accessories

Title: A Comprehensive Comparison of Hardware Parts Prices in Zhejiang Province, China

Title: Exploring the Excellence of Hardware Accessories Manufacturing in Huizhou