Title: Unlocking the Potential of Custom Metal Fabrication: A Comprehensive Guide to Mechanical Hardware Manufacturers

Unlocking the Potential of Custom Metal Fabrication: A Comprehensive Guide to Mechanical Hardware ManufacturersCustom metal fabrication is a powerful tool for mechanical hardware manufacturers looking to differentiate their products and gain a competitive advantage in the market. This comprehensive guide explores the key aspects of custom metal fabrication, including the benefits it offers, the various types of metal fabrication techniques available, and best practices for designing and executing custom metal fabrication projects.The guide begins by discussing the advantages of custom metal fabrication, such as its ability to create unique and high-quality products, its potential to reduce production costs, and its ability to meet specific customer needs. It then provides an overview of the different types of metal fabrication techniques, includingSheet Metal Forming, Die Casting, and Injection Molding.Next, the guide delves into best practices for designing and executing custom metal fabrication projects. This includes understanding the importance of accurate design drawings and specifications, selecting the right materials and suppliers, and ensuring proper quality control throughout the process.Throughout the guide, readers will also learn about common challenges faced by mechanical hardware manufacturers when implementing custom metal fabrication, such as managing project timelines and budgets, and working with specialized equipment and skilled technicians. The guide concludes with a summary of the key takeaways and recommendations for success in custom metal fabrication.

In today's fast-paced and ever-evolving industrial landscape, precision and efficiency are paramount. As manufacturers seek to stay ahead of the curve, the demand for custom metal fabrication solutions continues to soar. At the forefront of this trend are specialized mechanical hardware manufacturers who specialize in creating bespoke components and systems tailored to meet specific customer needs. In this article, we will delve into the world of custom metal fabrication, exploring what it means for manufacturers and how they can leverage this powerful tool to drive business growth.

The Power of Customized Metal Fabrication

Custom metal fabrication offers a range of benefits that set it apart from more standardized production techniques. Perhaps most significantly, it enables manufacturers to create highly unique and customized products that meet specific customer requirements. By working closely with clients during the design process, mechanical hardware manufacturers can ensure that their products not only look but function perfectly for their intended purpose. This level of customization is crucial in industries where precision and quality are paramount, such as aerospace, automotive, and medical devices.

Furthermore, custom metal fabrication allows for greater flexibility in terms of material choice and processing methods. Unlike mass production techniques, which often involve using the same base materials and manufacturing processes across a wide range of products, custom metal fabrication allows for a much more nuanced approach. By working with a variety of materials and processing techniques, manufacturers can create truly unique and specialized components that stand out from the competition.

Key Components of Successful Custom Metal Fabrication

While the benefits of custom metal fabrication are clear, implementing this technology effectively requires careful planning and execution. Here are some critical components to consider when developing a custom metal fabrication strategy:

1. Design: The first step in any custom metal fabrication project is to develop detailed designs that take into account the specific needs and specifications of the customer. This may involve collaboration with in-house engineers or external consultants to ensure that designs are both technically feasible and cost-effective.

2. Materials Selection: Once designs have been finalized, it's time to select the appropriate materials for the project. This may involve working with a variety of metals, composites, and other materials to find the best fit for the application. It's also important to consider factors such as weight, strength, corrosion resistance, and cost when making material choices.

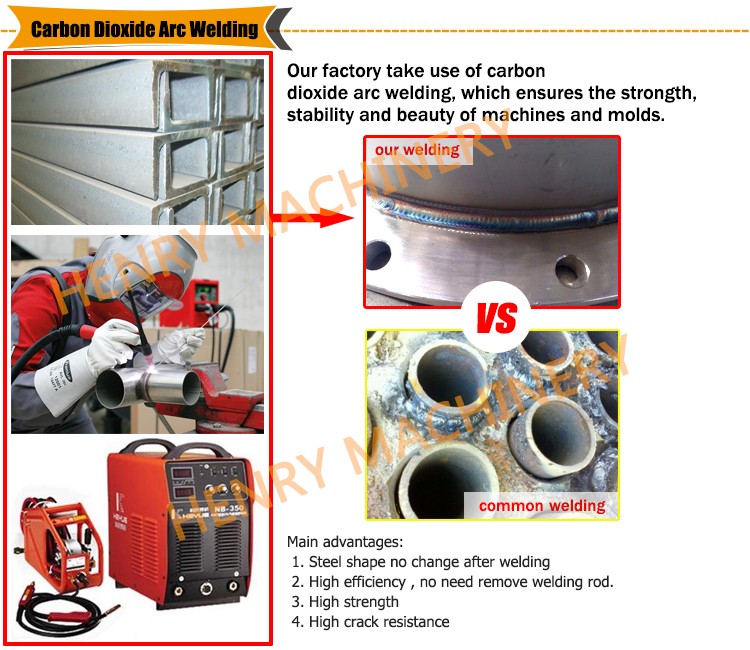

3. Manufacturing Process: The actual manufacturing process will depend on the nature of the project and selected materials. Common processes include milling, turning, drilling, welding, and additive manufacturing (such as 3D printing). Each process has its own strengths and weaknesses, and it's essential to choose the right one for the job.

4. Quality Control: To ensure that final products meet the required standards, it's crucial to implement rigorous quality control measures throughout the manufacturing process. This may involve using advanced testing equipment, following established quality protocols, and conducting regular inspections to catch any issues early on.

5. Collaboration: Finally, successful custom metal fabrication projects require close collaboration between manufacturers and their clients. This may involve regular meetings to review progress, providing feedback on design changes, and ensuring that final products meet expectations. By working closely with customers throughout the process, manufacturers can build strong relationships that lead to repeat business and referrals.

Conclusion

As the global marketplace continues to evolve, businesses must be prepared to adapt quickly to changing customer needs and industry trends. Custom metal fabrication offers a powerful tool for manufacturers looking to differentiate themselves from the competition and drive business growth. By leveraging cutting-edge technologies and collaborating closely with customers, mechanical hardware manufacturers can create truly unique and specialized components that meet even the most demanding specifications. With careful planning and execution, custom metal fabrication can help manufacturers achieve long-term success in an increasingly competitive marketplace.

Articles related to the knowledge points of this article:

Title: Customized Hardware and Sanitary Ware in Nanchang: A Comprehensive Guide

The Customization of Hardware in Ruian, China

Custom Hardware Supporting Equipment

Title: Crafting Custom Badges with Jian Hardware: An Illustrious Tradition of Quality and Excellence

Customized Xian Shelf Hardware for Your Convenience and Efficiency

Title: Custom Processing and Printing of Metals Hardware Ink in Meizhou - An Experts Guide