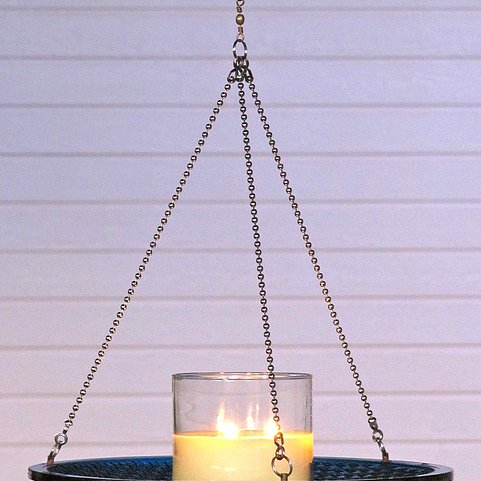

Light Fixture Hardware Components Factory: A Look Inside the Production Process

This article provides a glimpse into the production process of a light fixture hardware components factory. From raw material selection to the final assembly process, it highlights the various stages involved in creating high-quality products. The factory's attention to detail and commitment to quality control ensure that each component is meticulously inspected and tested to ensure its performance and longevity. Additionally, the factory's use of advanced technology and machinery in production further enhances the quality of its products. Whether you are looking to purchase lighting fixtures or explore a career in the lighting industry, this article provides an interesting and informative look at the behind-the-scenes processes that go into creating beautiful and functional lighting solutions.

In the lighting industry, there are many important components that make up a light fixture. One of these components is the hardware, which includes screws, bolts, washers, and other small parts that hold the light fixture together. These hardware components are often overlooked, but they are crucial to the stability and longevity of the light fixture.

The hardware components of a light fixture are typically made from metal, such as steel or aluminum. The metal is cut into shapes using a CNC machine, then drilled, tapped, and deburred to prepare for assembly. Next, the hardware components are coated with a protective finish to prevent corrosion and ensure their longevity.

The production process for light fixture hardware components is highly automated. Robots and machines perform many of the repetitive tasks, such as cutting, drilling, tapping, and deburring. This ensures consistency and precision in the production process. However, there are also many manual tasks involved in the production process, such as assembly, quality control, and packaging.

The quality control process is crucial in ensuring that each hardware component meets the required standards. Each component is inspected for defects and measured to ensure its accuracy. If any component fails to meet the standards, it is rejected and discarded.

Once the hardware components have been produced and passed quality control, they are packaged for shipment to the customer. The packaging process ensures that each component is properly protected for transportation and prevents any damage during shipping.

In conclusion, the production process for light fixture hardware components is a complex but essential part of the lighting industry. The hardware components produced by this factory are of high quality and meet the required standards. The automated production process ensures consistency and precision, while the manual tasks involved in the production process ensure that each component is properly inspected and packaged for shipment.

Articles related to the knowledge points of this article:

Suzhou Hardware Accessories: Quality and Innovation

Exploring the Excellence of Yancheng Universal Hardware Supply: A Comprehensive Overview

Title: Exploring the World of Sanitary Hardware Wholesale in Beijing

Title: Exploring the Procurement Price of Common Hardware Accessories in Meizhou