CNC Machining of Hardware Prototypes: A Custom Solution for Your Design Needs

CNC machining of hardware prototypes is a custom solution that can meet the design needs of any individual or business. This process allows for precision cutting and fabrication of materials to create functional prototypes that can be used for testing, evaluation, or demonstration purposes. CNC machining provides a cost-effective way to produce high-quality prototypes in a short amount of time, making it an ideal choice for designers, engineers, and product developers. By utilizing this method, you can bring your ideas to life and test them in a real-world environment before committing to expensive production runs. CNC machining of hardware prototypes is a versatile and efficient method that can help you bring your products to market quickly and successfully.

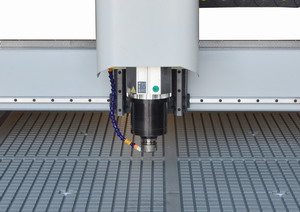

In today's fast-paced design and manufacturing industry, CNC (Computer Numerical Control) machining has become a crucial process for creating precision hardware prototypes. Hardware CNC hand板模型定制, as it is commonly known, involves the use of computer-controlled machines to cut, shape, or carve materials like metal, plastic, or wood into the desired product shape. This process allows for a high level of precision and repeatability, making it ideal for prototype manufacturing.

What are the benefits of using CNC machining for hardware prototypes?

• Precision: CNC machines can cut and shape materials with precision, ensuring that each prototype is made to the exact specifications of the design. This precision allows for a high level of accuracy in the prototype, reducing the need for further adjustments or modifications.

• Repeatability: CNC machines can consistently produce identical prototypes time and time again, ensuring that each one is identical to the original design. This repeatability is crucial in ensuring that the prototypes are reliable and accurate representations of the final product.

• Cost-effective: CNC machining can help reduce the cost of hardware prototype production by offering a highly efficient and automated process. By reducing the need for manual labour, CNC machining can help to keep costs low while maintaining high levels of quality and precision.

• Material versatility: CNC machines can work with a wide range of materials, including metal, plastic, wood, and even composite materials. This versatility allows designers to experiment with different materials to find the most suitable one for their prototype.

• Customization: CNC machining allows for a high level of customization in hardware prototype production. Whether it is a small component or an entire product, CNC machines can produce it according to the designer's specifications. This customization allows designers to create prototypes that are tailored to their specific needs.

In conclusion, CNC machining is an essential process for hardware prototype production. By offering precision, repeatability, cost-effectiveness, material versatility, and customization, CNC machining allows designers to create hardware prototypes that are both accurate and efficient. As such, it is no wonder that CNC machining has become a popular choice for hardware prototype production in recent years. Whether you are looking to create a small component or an entire product, CNC machining can help you achieve your design goals with precision and efficiency.

Articles related to the knowledge points of this article:

Custom Cabinet Hardware: The Complete Guide

Custom Silver Plating for Hardware

Title: Innovative Solutions from Shandong Factory for Metal Hardware customization

Title: Crafting the Perfect Sales Strategy: My Experience as a Custom Metals Dealer

ZHOUSHAN Ouwei Customized Hardware: Quality and Precision Meet in this Fishing City