Title: Custom Brass Etching in Taizhou, China

Taizhou, China is a city known for its brass etching industry. Custom brass etching is a popular service offered in the region, with many businesses offering their own unique designs and styles. The process of brass etching involves cutting away parts of the brass surface to create a desired pattern or design. This process can be done manually or using computers, depending on the complexity of the design. Brass etching is often used for decorative purposes, but it can also be used to create functional components for various industries. The custom brass etching industry in Taizhou has been growing steadily over the years, with more and more businesses offering this service to meet the demand from customers.

Taizhou, a city in the eastern region of China, is renowned for its diverse industrial sectors, one of which is the production of high-quality brass etched components. The brass etching industry in Taizhou has been thriving for years, offering customized solutions to various industrial applications. This article delves into the brass etching customization process at a local factory in Taizhou.

In recent years, the brass etching industry in Taizhou has been undergoing significant changes. With advancements in technology and the evolving market demands, factories have been forced to adapt to new production methods and materials. One such change is the shift from traditional brass to stainless steel, which has become the material of choice for many industries due to its durability and resistance to corrosion.

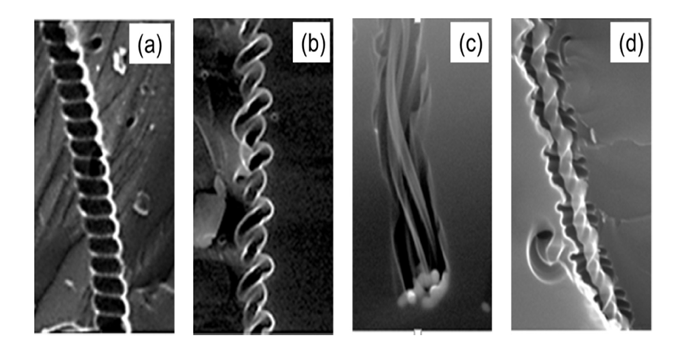

The process of brass etching customization at a factory in Taizhou involves several steps. The first step is to identify the specific application for which the brass etched component is intended. This allows the factory to determine the design, material, and production process that will be most suitable for the intended use. Next, the factory will provide a sample of the desired component for approval by the customer. This sample is made using a CAD (Computer-Aided Design) program to ensure precision and accuracy.

Once the sample is approved, the factory will move onto the production phase. This involves cutting, bending, and polishing the brass or stainless steel material to achieve the desired shape and dimensions. Then, the components are sent through an etching machine, which uses a chemical process to remove sections of the material, creating the desired pattern or design. The process is controlled by computer software, ensuring precision and consistency.

After etching, the components undergo a series of quality control checks to ensure they meet the specified standards. This includes checking for defects, measuring dimensions, and testing performance. If any issues are found, the factory will address them immediately and notify the customer of any necessary adjustments or modifications.

Once the quality control checks are completed, the factory will package and ship the brass etched components to the customer. The packaging process ensures that each component is protected from damage during transportation and storage. The factory will also provide necessary documentation, such as invoices and product specifications, to ensure smooth and efficient communication with the customer.

In conclusion, brass etching customization in Taizhou, China, involves several steps to ensure precision, quality, and customer satisfaction. Factories in this region have been adapting to new production methods and materials to meet evolving market demands. The result is high-quality brass etched components that are tailored to specific applications and industries.

Articles related to the knowledge points of this article:

Whole-House Custom Hardware Brands: A Comprehensive Guide

Customized Hardware Components by Weiyi - A Premier Provider of Quality and Precision