Precision Hardware Customization for Doors and Windows - An Insight into the Manufacturing Process

Precision Hardware Customization for Doors and Windows presents an insight into the manufacturing process of customizing hardware for doors and windows. The article explains the importance of precision manufacturing in creating high-quality products tailored to specific needs. It discusses the steps involved in the manufacturing process, from design and material selection to machining and assembly. The article also highlights the benefits of hardware customization, including improved functionality, aesthetics, and performance. Precision Hardware Customization for Doors and Windows provides a detailed understanding of the manufacturing process and demonstrates how precision manufacturing techniques can be applied to create high-quality, customized products.

As the construction industry continues to evolve, so too does the demand for precision hardware customization for doors and windows. From residential to commercial projects, high-quality, customized hardware is essential to ensure the smooth operation and longevity of these essential building components. In this article, we will delve into the manufacturing process of precision hardware customization for doors and windows, highlighting the key stages and considerations throughout the production line.

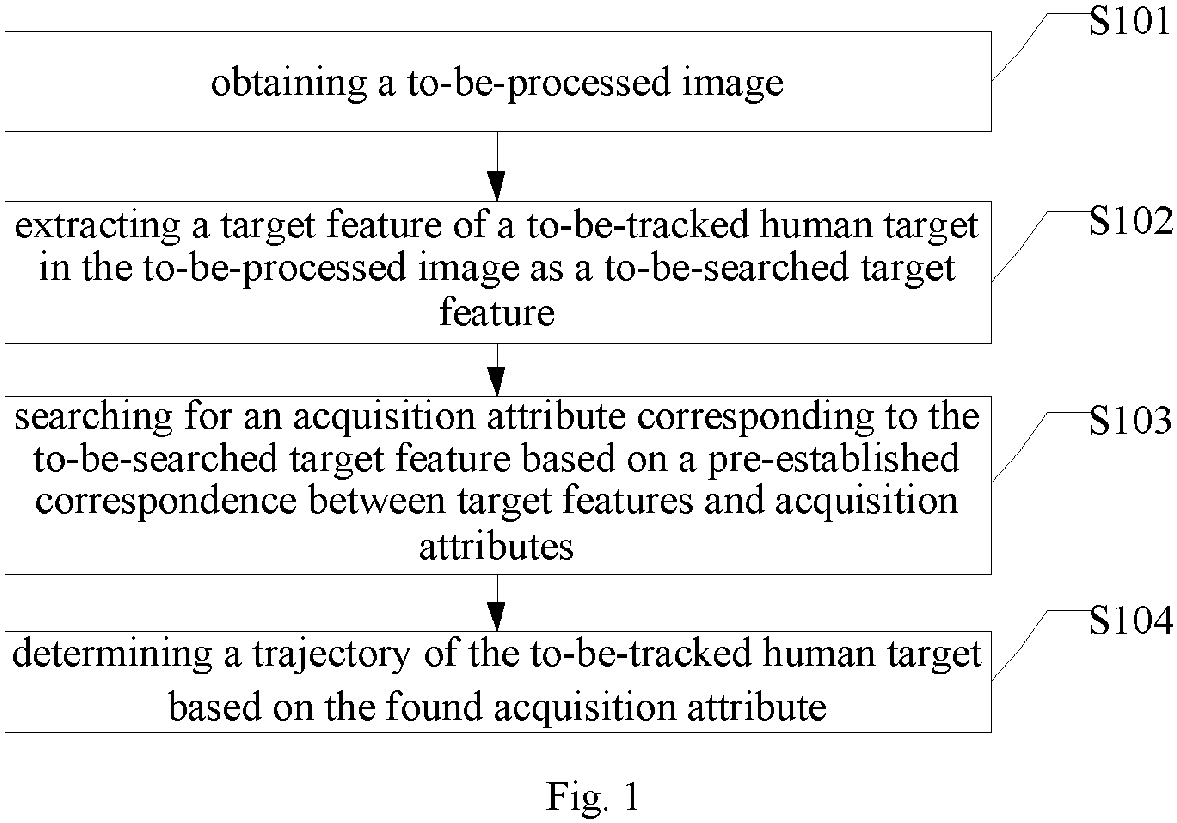

1、Design and Material Selection

The first step in the manufacturing process is the design and material selection. This stage involves determining the type of hardware required for the specific application, such as doors or windows, and selecting the appropriate materials to ensure durability, performance, and aesthetic appeal. Factors such as cost, weight, and environmental conditions are also taken into consideration.

2、Tooling and Cutting

Once the design and material selection are completed, the next step is tooling and cutting. This involves creating molds or templates to shape the raw material into the desired hardware components. Precision cutting techniques are then used to cut out the individual pieces from the selected material.

3、Processing and Assembly

The next stage is processing and assembly. This involves cleaning, polishing, and inspecting each piece to ensure it meets the required standards. The pieces are then assembled together using precision techniques to create the final hardware product. Assembly processes can vary depending on the type of hardware being manufactured.

4、Quality Assurance

Quality assurance is a crucial stage in the manufacturing process. It involves testing each individual piece to ensure it operates smoothly, meets performance standards, and is free from defects. Quality assurance processes may include visual inspections, mechanical testing, and thermal cycling testing to simulate real-world conditions.

5、Packaging and Shipping

The final step is packaging and shipping. The finished products are packaged in appropriate containers to protect them from damage during transportation. Shipping arrangements are then made to deliver the products to their intended destinations, either directly to construction sites or to distributors for onward sale to end users.

In conclusion, precision hardware customization for doors and windows is a complex but essential process that requires a high level of skill and attention to detail. By understanding the manufacturing process from start to finish, it is possible to ensure that each individual piece of hardware meets the highest standards of performance and durability.

Articles related to the knowledge points of this article:

Title: Customizing Metallic Components in Bengbu: The Ultimate Guide to Rubber Bending

Customizing Jiangsu Hardware Oven for Baking

Title: Custom Processing of Hardware and Sheet Metal in Yunnan

Title: Crafting Custom Sanitary Ware in Chongqing: The Art of General Hardware Levers