Title: Exploring the Cost of Production for五金配件 Manufacturers: A Comprehensive Guide

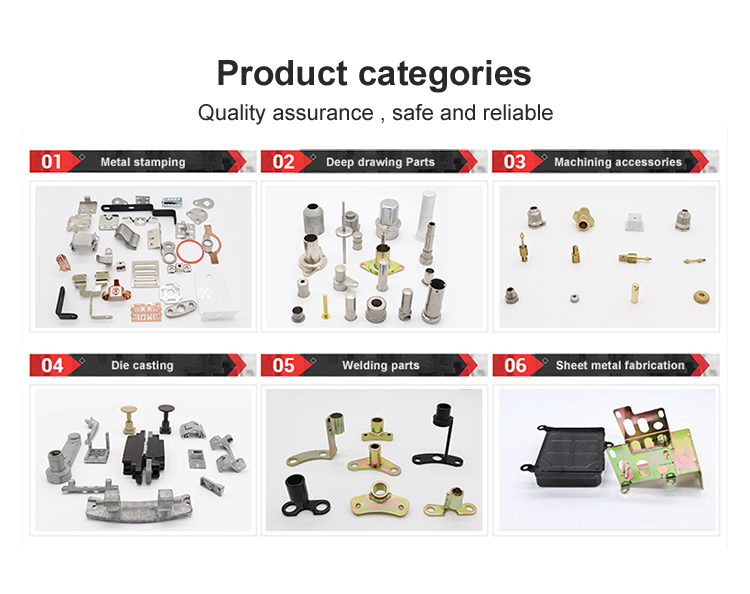

Title: Exploring the Cost of Production for五金配件制造商:全面指南As global manufacturers of hardware and accessories, understanding the cost of production is crucial to maintaining competitive pricing and maximizing profitability. A comprehensive guide to this topic explores various factors that contribute to the overall cost of production, including raw material costs, labor expenses, overhead costs, and equipment usage.Raw material costs are a significant factor in manufacturing hardware and accessories, as they account for a large portion of production expenses. Understanding the fluctuations in raw material prices and developing effective procurement strategies can help manufacturers reduce their dependence on external suppliers and manage their inventory more efficiently.Labor expenses also play a critical role in the cost of production. This includes not only the salaries and wages paid to employees but also benefits, training, and labor turnover costs. To minimize labor expenses, manufacturers can implement efficient workforce management practices, such as training programs, flexible schedules, and incentives for high performers.Overhead costs, which include rent, utilities, insurance, and other administrative expenses, can add up quickly. By identifying areas where overhead costs can be reduced or streamlined, such as by implementing energy-saving measures or consolidating office spaces, manufacturers can improve their bottom line.Equipment usage is another significant cost factor. Maintaining and updating equipment can be costly, so it's essential to prioritize investments based on their potential impact on productivity and efficiency. Regular maintenance, predictive maintenance initiatives, and the use of data analytics can help optimize equipment utilization and reduce downtime.In conclusion, understanding the cost of production for hardware and accessory manufacturers requires careful analysis of various factors that contribute to overall expenses. By implementing strategies to reduce reliance on external suppliers, optimize labor expenses, streamline overhead costs, and improve equipment usage efficiency, manufacturers can maintain competitive pricing and maximize profitability.

Introduction:

The manufacturing process of五金配件 is a complex task that requires precision, skill, and expertise. The cost of production can vary greatly depending on several factors such as raw material prices, labor costs, equipment maintenance, and overhead expenses. In this article, we will explore the various aspects that contribute to the cost of production for五金配件 manufacturers and provide you with a comprehensive guide to help you make informed decisions when it comes to pricing your products.

Raw Material Costs:

One of the most significant contributors to the cost of production for五金配件 manufacturers is the price of raw materials. Raw materials are the basic building blocks of any product, and their cost can fluctuate significantly based on market conditions. Common raw materials used in the manufacture of metal components include aluminum, steel, stainless steel, and titanium. These materials can come from various sources, such as mills, distributors, or scrap yards. It is essential to keep track of the prices of raw materials in real-time to avoid overspending or running out of stock.

Labor Costs:

Another critical factor that affects the cost of production for五金配件 manufacturers is labor. Labor costs can vary widely depending on factors such as experience level, skillset, working hours, and location. In addition to hourly wages, there are other expenses associated with labor that need to be taken into account, such as benefits, training, and productivity incentives. To minimize labor costs, manufacturers can consider implementing automation, streamlining processes, and improving employee training programs.

Equipment Maintenance:

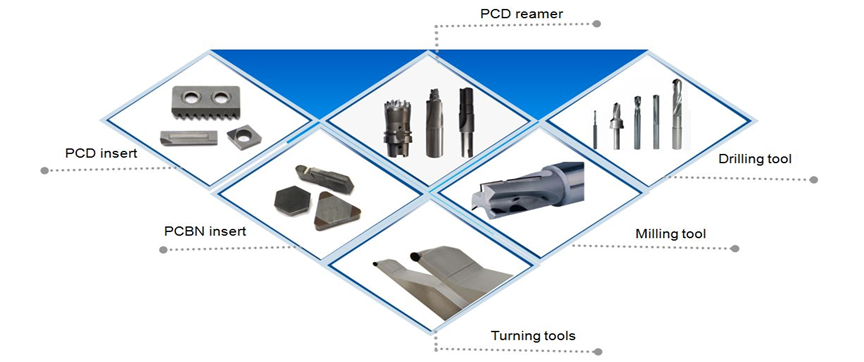

Proper maintenance of manufacturing equipment is crucial for maintaining efficiency and reducing downtime. Equipment maintenance costs can include parts replacements, repairs, energy consumption, and operating expenses. Manufacturers should establish a regular maintenance schedule for their equipment to prevent costly breakdowns and maximize uptime. Additionally, investing in energy-efficient equipment can help reduce energy costs and improve overall sustainability.

Overhead Expenses:

Overhead expenses are indirect costs that do not directly relate to the production process but are necessary for running a business. These expenses include rent, utilities, insurance, marketing, and accounting fees. It is essential to factor these expenses into the cost calculation to obtain an accurate understanding of the final selling price. To minimize overhead expenses, manufacturers can consider negotiating better rates with suppliers or service providers or adopting more streamlined financial management practices.

Pricing Strategies:

Once you have determined the cost components involved in producing五金配件, you can use them to develop a pricing strategy that takes into account your target market, competition, and business objectives. There are several pricing strategies you can consider, including:

1. Cost-Plus Pricing: This approach involves adding a markup to the unit cost of production to cover your overhead expenses and desired profit margin.

2. Value-Based Pricing: This strategy aims to price products based on their perceived value to customers. You can use various techniques such as competitive analysis or customer surveys to determine the optimal pricing point.

3. Dynamic Pricing: This method adjusts prices based on supply and demand trends or time-of-year variations. Dynamic pricing can help you maximize revenue during peak periods while minimizing losses during low-demand times.

4. Bundled Pricing: This strategy involves offering discounts or promotions on multiple products or services at once rather than individually pricing each item. This approach can help you increase sales volume and improve customer loyalty.

Conclusion:

In conclusion, the cost of production for五金配件 manufacturers can vary greatly depending on several factors such as raw material prices, labor costs, equipment maintenance, overhead expenses, and pricing strategies. By understanding these cost components and developing a comprehensive pricing strategy that considers your business objectives and target market, you can ensure profitability while providing high-quality products to your customers.

Articles related to the knowledge points of this article:

Title: Technical Guidance for Small Hardware Accessories in Hubei Province

Bathroom Hardware Accessories: A Comprehensive Guide

Contact Person for Special Metal Components in Nantong

Title: Hardware Fittings Procurement Contract

Title: Comprehensive Guide to Changsha Hardware Accessories Prices: Updated List of Best Deals

Title: Understanding the Purchasing Prices of Liaoning Specific Hardware Accessories