Title: Customization of CNC Metal Hardware in Jiangsu Province: A Comprehensive Guide

Customization of CNC Metal Hardware in Jiangsu Province has become a popular trend due to its numerous benefits. This comprehensive guide provides an overview of the process, including the necessary steps and considerations. The first step is to understand the client's requirements and design specifications. The next step involves selecting the right materials for the project, such as aluminum or steel. The software must then be used to create a 3D model of the desired product. Once the model is created, it can be sent to the CNC machine for production. During the production process, it is important to monitor the progress regularly to ensure that the quality of the final product meets the client's expectations. After production, the hardware must be thoroughly checked for any defects before being delivered to the customer. In conclusion, customization of CNC Metal Hardware in Jiangsu Province is a complex process that requires careful planning and attention to detail. By following this comprehensive guide, businesses can ensure that their products meet high standards and provide value to their customers.

Introduction

The manufacturing industry has been revolutionized by the advancements in technology, particularly in the field of computer numerical control (CNC) machines. CNC machines have significantly improved efficiency, productivity, and precision in various manufacturing processes. One such process is the creation of metal hardware components, which require high-quality standards and precise measurements. In recent years, there has been a growing demand for CNC metal hardware customization in Jiangsu province, China. This article aims to provide a comprehensive guide on the customization of CNC metal hardware in Jiangsu, covering various aspects such as the process, materials, equipment, and market trends.

Section 1: The Process of Customized CNC Metal Hardware in Jiangsu

The process of customized CNC metal hardware in Jiangsu involves several steps, starting from design to production. Here's an overview of each step:

1、Design: The first step in creating customized CNC metal hardware is designing the product using CAD (Computer-Aided Design) software. The designer inputs specifications and requirements for the product, including dimensions, shape, material type, and other necessary details. Once the design is finalized, it is sent to the next step.

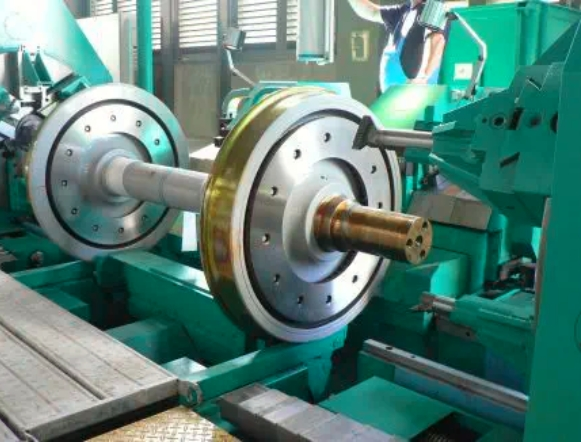

2、Prototyping: After the design is approved, a prototype is created using a CNC milling machine or a CNC turning center. The prototype serves as a proof of concept, allowing the designer and manufacturer to test the feasibility of the product and identify any potential issues before mass production.

3、Mass Production: Once the prototype is validated, the manufacturer proceeds to mass produce the custom CNC metal hardware. The production process involves programming the CNC machine with the designed specifications and setting up the machinery for cutting, drilling, and other machining operations. The manufactured parts are then assembled and quality checked before being packaged and shipped to customers.

4、Quality Control: Throughout the entire production process, rigorous quality control measures are implemented to ensure that the custom CNC metal hardware meets the required standards. This includes checking for accuracy, consistency, and surface finish during both the prototyping and mass production stages. Any issues identified during quality control are addressed promptly to prevent delays in delivery or substandard products.

5、Delivery and Support: Once the custom CNC metal hardware is complete and passes quality control, it is shipped to the customer's location. The manufacturer also provides technical support to assist with the integration of the hardware into the customer's existing systems or any troubleshooting that might arise post-delivery.

Section 2: Materials Used in Customized CNC Metal Hardware in Jiangsu

The choice of materials used in customized CNC metal hardware depends on various factors such as functional requirements, aesthetics, cost-effectiveness, and environmental considerations. Some of the commonly used materials in Jiangsu include:

1、Steel: Steel is one of the most common materials used in CNC metal hardware due to its strength, durability, and versatility. It can be processed into various shapes and sizes, making it suitable for a wide range of applications. Popular grades of steel used in CNC metal hardware include carbon steel, stainless steel, and alloy steels.

2、Aluminium: Aluminium is another popular material used in CNC metal hardware due to its lightweight properties, excellent corrosion resistance, and high strength-to-weight ratio. It is commonly used in aerospace, automotive, and consumer electronics industries. Aluminium alloys offer additional properties such as heat resistance, conductivity, and flexibility, making them suitable for specific applications.

3、Titanium: Titanium is a high-strength, lightweight material that offers excellent mechanical properties and superior corrosion resistance compared to other metals. It is commonly used in aerospace, medical, and automotive industries due to its ability to withstand extreme temperatures and pressure. Titanium alloys are available in different grades and configurations depending on the application requirements.

4、Polymers: Plastics and polymers are increasingly being used in custom CNC metal hardware due to their lightweight properties, low cost, and ease of processing. Common plastics used in CNC metal hardware include polycarbonate (PC), polyethylene (PE), and polypropylene (PP). Polymer materials are suitable for applications where strength and durability are not critical but aesthetics and flexibility are important considerations.

Section 3: Equipment Required for Customized CNC Metal Hardware in Jiangsu

The following equipment is typically required for customized CNC metal hardware production in Jiangsu:

1、Computer numerically controlled (CNC) machine: A CNC machine is essential for producing accurate and precise custom metal parts quickly. There are various types of CNC machines available in Jiangsu, including vertical machining centers (VMCs), horizontal machining centers (HMCs), and multi-axis machining centers (MACs). Each type offers different capabilities based on the specific application requirements.

2、Milling machine: A milling machine is used for cylindrical or angular cutting of metals, including steel, aluminum, and titanium alloys. There are various types of milling machines available in Jiangsu, including vertical milling machines (VMMs), horizontal milling machines (HMMs), and planer-milling machines (PMMs). Each type offers different capabilities based on the specific application requirements.

3、Lathe machine: A lathe machine is used for shaping metals by rotating a workpiece around a central axis. There are various types of lathe machines available in Jiangsu, including vertical lathe machines (VLMs), horizontal lathe machines (HLMs), and compound lathe machines (CLMs). Each type offers different capabilities based on the specific application requirements.

4、Drilling machine: A drilling machine is used for drilling holes in metals to create fasteners or other functional features. There are various types of drilling machines available in Jiangsu, including vertical drilling machines (VDMs), horizontal drilling machines (HDMs), and down-the-hole (DTH) drilling machines. Each type offers different capabilities based on the specific application requirements.

5、Welding machine: A welding machine is used to join two or more metals together by applying heat and pressure. There are various types of welding machines available in Jjiangsu

Articles related to the knowledge points of this article:

Luo Yang Hardware Customization Shop

Custom Hardware Solutions from Dingzhi Hardware