Title: Custom Processing of Hardware Etching in Haining

In Haining, a city in China's Zhejiang province, there is a thriving hardware industry that produces a wide range of products from plastic injection molding to metal machining. One of the important processes in this industry is hardware etching, which is a technique that involves removing material from the surface of a metal object using an acid or other chemical solution. Custom processing of hardware etching in Haining has become increasingly popular in recent years due to the high quality and precision of the work. Etching companies in Haining have invested in advanced technology and equipment to ensure that they can meet the demands of their customers. Whether it is for automotive, aerospace, or medical applications, these companies are able to provide top-quality hardware etching services.

Hardware etching is a crucial process in manufacturing, which allows for precision removal of material to create intricate designs or shapes. Etching can be done using various methods, such as chemical, mechanical, or thermal etching. In Haining, a city in China, there are numerous hardware etching processing factories offering customized services to meet the diverse needs of their clients.

In recent years, the hardware industry in Haining has made significant advancements, incorporating modern technology and techniques to enhance the quality of their products. Etching processing in particular has become more sophisticated, with many factories offering customized services tailored to meet the individual needs of their customers. This approach allows for greater flexibility and precision in manufacturing, resulting in high-quality hardware components that are crucial for various applications.

Custom processing of hardware etching in Haining involves several steps. Firstly, the material is selected based on the specific application and requirements. Common materials used include metal, plastic, and glass. Once the material is selected, it is then prepared for etching by cleaning and coating it with a protective layer to ensure that only the desired areas are etched.

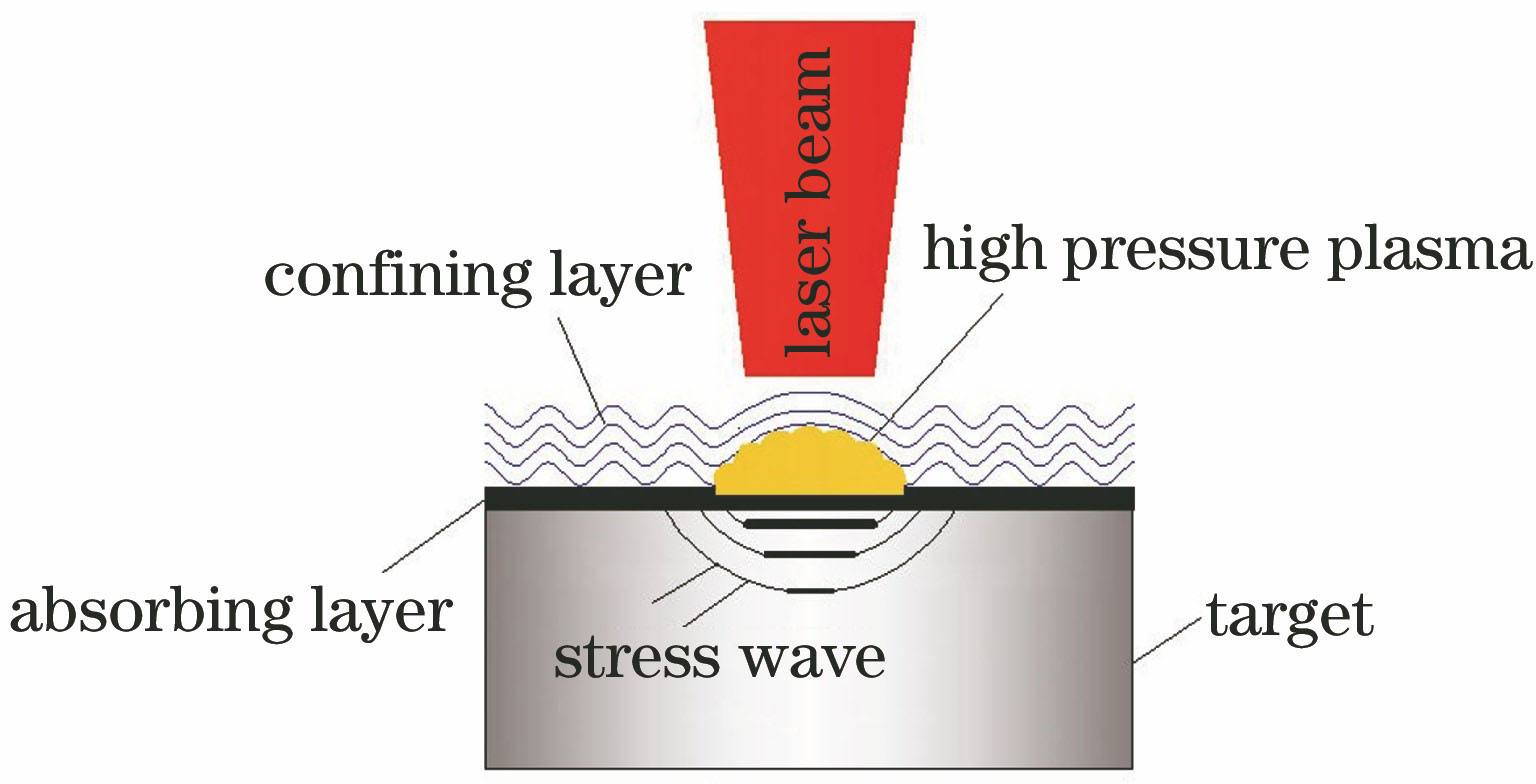

Next, the etching process is carried out using either chemical, mechanical, or thermal etching techniques. Chemical etching involves using acids or bases to remove material from the surface. Mechanical etching, on the other hand, utilizes mechanical abrasives to achieve material removal. Thermal etching, meanwhile, uses heat to induce chemical reactions that result in material removal. Each of these techniques has its own advantages and disadvantages, depending on the specific application and requirements.

After the etching process is completed, the material is then inspected for quality assurance purposes. This involves checking for defects such as uneven etching, material residue, or damage to the protective layer. If any defects are found, the material is either discarded or returned to the previous step for further processing.

Finally, the finished product is packaged and shipped to the customer. Packaging is essential to ensure that the product remains intact during transportation and storage. Additionally, it also provides protection against dust and moisture, which can affect the performance of the hardware component.

In conclusion, custom processing of hardware etching in Haining has become an integral part of the hardware manufacturing industry. By offering customized services tailored to meet the individual needs of their customers, these factories have been able to enhance the quality of their products while remaining cost-effective. The use of modern technology and techniques has also allowed for greater flexibility and precision in manufacturing, resulting in high-quality hardware components that are crucial for various applications.

Articles related to the knowledge points of this article:

Title: MUSE V6 Whole-House Customized Hardware

Custom Metal Light Fixtures: Creating a Unique and Stylish Statement for Your Home

Customizing Metal Suctions in Maoming: A Journey of Innovation and Precision