Automated Equipment Hardware Fittings Processing

This paper introduces the processing technology of automated equipment hardware fittings. It explains the importance of hardware fittings in automated equipment and the impact of processing technology on the performance of the equipment. The processing technology discussed includes material selection, design optimization, manufacturing processes, and quality control. It also highlights the challenges in processing technology and measures to address these challenges. Finally, it summarizes the achievements and future trends of automated equipment hardware fittings processing technology.

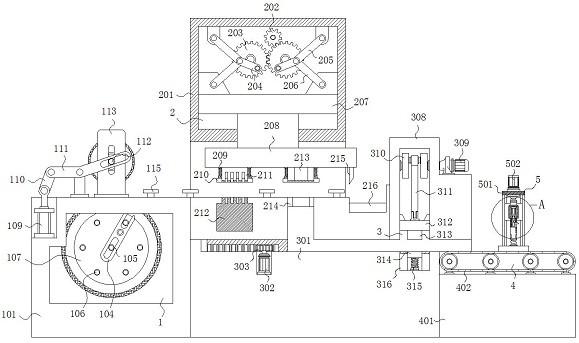

In recent years, with the continuous development of industrial technology, the processing of hardware fittings for automated equipment has become a crucial component in various industries. This processing involves the use of precision machining techniques to manufacture and assemble metal parts that are essential for the smooth operation of automated machinery. This article will explore the importance of hardware fittings processing in automated equipment, the various types of processing techniques employed, and the industry standards and best practices that ensure the quality and reliability of these components.

Firstly, let’s talk about what hardware fittings are. Hardware fittings, also known as fasteners, are small metal components that are used to connect, support, or fasten other components together. In automated equipment, these fittings are crucial for maintaining the structural integrity and functionality of the machinery. Therefore, it is essential to use high-quality materials and precision machining techniques to manufacture these fittings.

Secondly, let’s discuss the processing techniques employed in hardware fittings manufacturing. There are several techniques that are commonly used, including cutting, grinding, polishing, and assembly. Each of these techniques requires a high level of precision and accuracy to ensure that the fittings meet the required specifications. Additionally, modern manufacturing facilities often use automated machines to perform these tasks, which not only improves productivity but also ensures consistency in quality.

Thirdly, let’s talk about industry standards and best practices in hardware fittings processing. To ensure the quality and reliability of these components, it is essential to adhere to strict industry standards and best practices. This includes using high-quality materials, implementing rigorous quality control measures, and employing experienced personnel who understand the importance of precision machining. By following these standards and practices, manufacturers can ensure that their products meet the high demands of automated equipment operators.

In conclusion, hardware fittings processing is a crucial aspect of automated equipment manufacturing. It involves using precision machining techniques to manufacture metal parts that are essential for the smooth operation of automated machinery. By understanding the importance of hardware fittings processing, employing effective processing techniques, and adhering to industry standards and best practices, manufacturers can produce high-quality hardware fittings that are reliable and meet the demands of their customers.

Articles related to the knowledge points of this article:

Aluminum Alloy Door and Window Hardware Fittings

The Art and Science of Processing Glass Door Hardware in Guangdong

Marine Hardware Fittings: The Vital Components of Naval Architecture