The Application of Bearing in Hardware Fittings

Bearings are important components in hardware fittings, playing a crucial role in supporting and facilitating the rotation of shafts and other mechanical parts. In this article, we will explore the application of bearings in hardware fittings, emphasizing their essential role in various mechanical systems.Firstly, bearings are used in various types of machinery to support shafts and other mechanical parts. They facilitate smooth rotation and reduce friction between moving parts, providing efficient transmission of power. In addition, bearings also protect shafts from damage due to vibration and impact.Secondly, bearings are integral to the performance of many industrial machines. They ensure smooth and efficient operation of machines, reduce energy consumption, and enhance machine durability. By supporting shafts and other mechanical parts, bearings help to reduce wear and tear on the machine, prolonging its lifespan.Thirdly, bearings are essential for the smooth operation of transportation equipment such as cars, trucks, and trains. They support the shafts of various mechanical systems, including engines, transmissions, and steering systems, ensuring efficient transmission of power and smooth movement of the vehicle.In conclusion, bearings play a crucial role in hardware fittings and mechanical systems. They support shafts and other mechanical parts, facilitate smooth rotation, reduce friction and wear, protect against vibration and impact damage, ensure efficient power transmission, and contribute to the overall performance and lifespan of the machine or vehicle.

In the hardware fittings industry, bearings play a crucial role. They are essential components that help to ensure the smooth and efficient operation of various machines and equipment. From large industrial machines to small consumer products, bearings are present in almost every aspect of hardware fittings.

In this article, we will explore the role of bearings in hardware fittings and how they contribute to the overall performance and lifespan of various products. We will also discuss the types of bearings commonly used in hardware fittings and how to choose the right bearing for a specific application.

Role of Bearings in Hardware Fittings

In hardware fittings, bearings serve as important mechanical components that help reduce friction and support rotational motion. They are commonly used in shafts, gears, and other rotating parts to ensure smooth and efficient operation. By reducing friction, bearings can help to increase the lifespan of the equipment they are used in.

Types of Bearings in Hardware Fittings

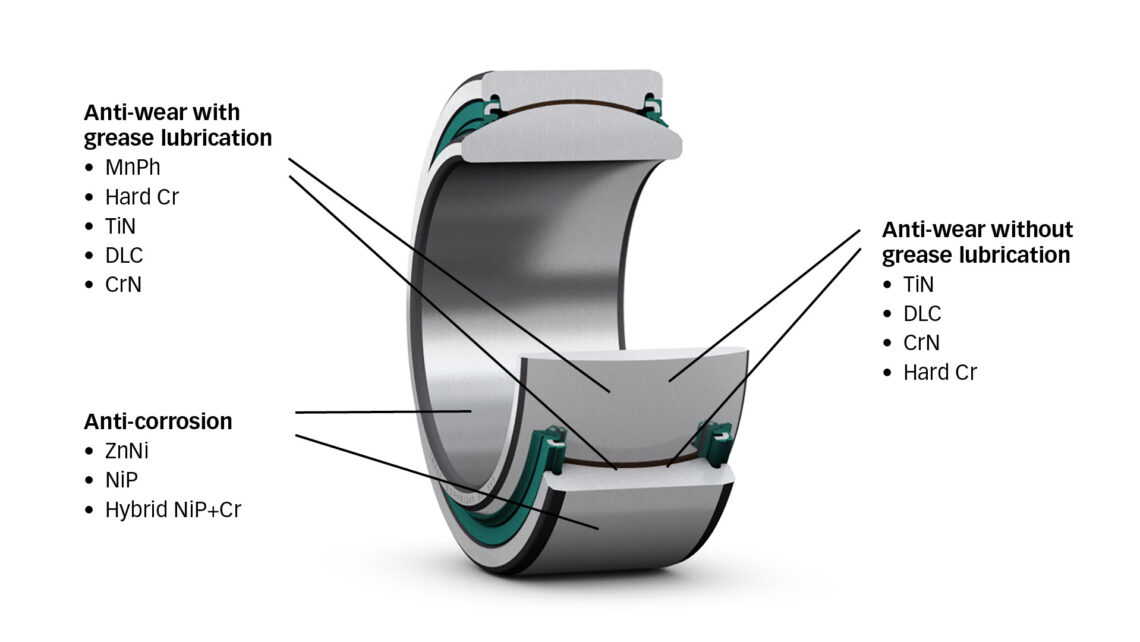

There are several types of bearings commonly used in hardware fittings, each with its own unique characteristics and applications. These include:

Ball Bearings: These bearings consist of balls enclosed in a metal or plastic cage. They are designed to support high loads and can handle high speeds. Ball bearings are commonly used in industrial machinery, automotive applications, and consumer products.

Roller Bearings: Roller bearings have rollers rather than balls enclosed in a cage. They are designed to support heavy loads at low speeds. Roller bearings are commonly used in industrial machinery, such as mills and conveyors, as well as in automotive applications.

Plain Bearings: Plain bearings, also known as bushing or sleeve bearings, do not have any rolling elements. Instead, they consist of a metal or plastic ring that allows for linear motion between two surfaces. Plain bearings are commonly used in automotive applications, such as clutches and gears, as well as in industrial machinery.

Angular Contact Bearings: Angular contact bearings have a single row of balls or rollers that make contact with the inner and outer races at an angle. This type of bearing can support both radial and axial loads simultaneously. Angular contact bearings are commonly used in high-speed applications, such as automotive wheels, industrial machinery, and consumer products.

Choosing the Right Bearing for an Application

When choosing a bearing for a specific application, several factors need to be considered, including:

Load: The bearing must be able to support the load it will be subjected to during operation. Both ball and roller bearings can handle heavy loads, but plain bearings are better suited for low-load applications.

Speed: The speed at which the bearing will operate also needs to be considered. Ball bearings are designed to handle high speeds, while roller bearings are better suited for low-speed applications.

Environment: The environment in which the bearing will operate can also affect its selection. For example, if the bearing will be exposed to high temperatures or harsh chemicals, it may need to be made from a material that can withstand these conditions.

Cost: The cost of the bearing is always a consideration, as it can affect the overall profitability of the product it is being used in. Plain bearings are generally less expensive than ball or roller bearings, but they may not be suitable for all applications due to their lack of rolling elements.

In conclusion, bearings play a crucial role in hardware fittings by reducing friction and supporting rotational motion. By understanding the types of bearings commonly used in hardware fittings and how to choose the right bearing for a specific application, engineers and designers can ensure that their products have smooth and efficient operation while maximizing lifespan and profitability.

Articles related to the knowledge points of this article:

Title: An Insight into Jiangxis Trendy Backpack Hardware Accessories

Expandable Table Hardware Accessories Plot

Title: The Diversification of Jiangyin Comprehensive Hardware Accessories Processing Types