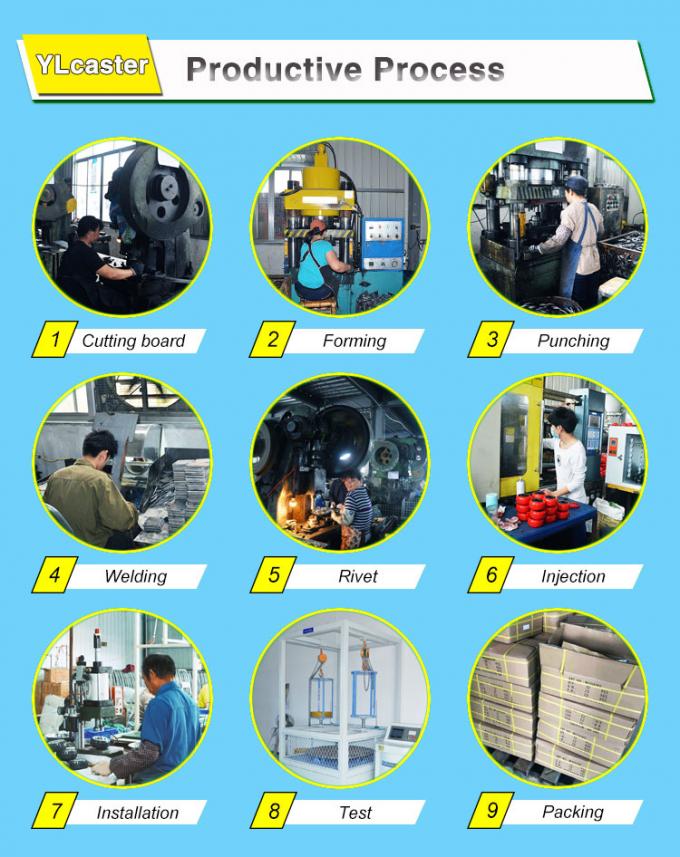

Title: Five-Hardware Fitting Production Equipment

This article introduces the production equipment of Five-Hardware Fitting, which includes a variety of machines and tools to ensure the quality and efficiency of the products. The equipment includes CNC machines, conventional machining tools, and inspection devices to ensure that each part is precisely made and meets the specified standards. The company also utilizes robotics technology to automate certain processes, improving productivity and reducing human error. Five-Hardware Fitting's production equipment is designed to ensure that its products are of the highest quality and meet the demands of its customers.

Hardware fittings are important components in various manufacturing industries, playing a crucial role in connecting, supporting, and protecting the structures they are used in. As such, the production equipment used to manufacture these fittings must be designed to meet the high standards and demands of the industry. This article will explore the various types of equipment used in the production of hardware fittings, as well as their features and applications.

1、CNC Machines

CNC (Computer Numerical Control) machines are essential in the production of hardware fittings due to their precision and accuracy in cutting and machining metal. These machines can be programmed to perform a wide range of operations, including cutting, drilling, grinding, and polishing, which are necessary to produce high-quality hardware fittings. CNC machines also offer high productivity, as they can work continuously for long hours without requiring breaks or operator intervention. This allows for increased output of hardware fittings, reducing production time and cost.

2、Metal Cutting Machines

Metal cutting machines are another essential piece of equipment in hardware fitting production. These machines use cutting tools to remove material from metal workpieces, creating the desired shape and size of the hardware fittings. Metal cutting machines can be either manual or automated, with automated machines offering increased productivity and precision. By using these machines, manufacturers can produce hardware fittings with consistent quality and accuracy.

3、Drilling Machines

Drilling machines are crucial for creating holes in hardware fittings. These machines use rotating drill bits to cut through metal, creating smooth and accurate holes that are necessary for assembly and installation. Drilling machines can be either stationary or portable, with portable machines offering increased versatility and convenience for use on-site. By using drilling machines, manufacturers can ensure that their hardware fittings meet the required specifications and standards.

4、Grinding Machines

Grinding machines are essential for achieving the desired surface finish and precision of hardware fittings. These machines use coated or unglazed abrasives to remove material from the surface of the workpiece, creating a smooth and accurate finish that is necessary for the longevity and performance of the hardware fittings. Grinding machines can be either manual or automated, with automated machines offering increased productivity and precision. By using these machines, manufacturers can produce hardware fittings with consistent quality and performance.

5、Polishing Machines

Polishing machines are the final step in achieving the desired appearance and quality of hardware fittings. These machines use polishing compounds or pastes to smoothen and enhance the surface finish of the workpiece, creating a shiny and aesthetically pleasing appearance that is desired for many hardware fittings. Polishing machines can be either manual or automated, with automated machines offering increased productivity and precision. By using these machines, manufacturers can produce hardware fittings that meet the visual standards and expectations of their customers.

In conclusion, the production equipment used in hardware fitting manufacturing must be designed to meet the high standards and demands of the industry. By using CNC machines, metal cutting machines, drilling machines, grinding machines, and polishing machines, manufacturers can produce hardware fittings with consistent quality, precision, and appearance that meet the requirements of their customers. These machines not only ensure high-quality production but also increase productivity and efficiency in the manufacturing process.

Articles related to the knowledge points of this article:

Shoe Hardware Accessories: Key Components for a Perfect Fit

Title: Shanghais Nuclear Power Hardware Accessory Quotation Network: A Comprehensive Guide

Guangzhou Furniture Hardware Accessories Market

Title: New Price Quote for Imported Hardware Components in Ninghe District