Title: Crafting Custom Metalwork: A Comprehensive Guide to Professional Metalworking

Crafting Custom Metalwork: A Comprehensive Guide to Professional MetalworkingMetalworking is an art form that involves shaping and manipulating metal using various tools and techniques. For those who wish to pursue a career in this field, it is important to have a comprehensive understanding of the principles and practices involved. This guide provides a step-by-step approach to learning professional metalworking, covering topics such as safety, tool selection, design, fabrication, and finishing. It also includes practical advice on how to establish a successful business and market your work. Whether you are a beginner or an experienced metalworker, this guide will help you to develop the skills and knowledge needed to create custom metalwork that stands out from the crowd. By following the steps outlined in this guide, you can achieve your goals and build a rewarding career in metalworking.

Introduction:

In the world of industrial production, metalworking is an essential process that involves cutting, shaping, and joining metals to create a wide range of products. Whether you're working on small-scale projects or large-scale manufacturing, custom metalwork can help you achieve your goals quickly and efficiently. With the right tools and techniques, you can produce high-quality metal components that meet your specific requirements. In this guide, we will explore the basics of custom metalworking, including different types of metalwork processes, tools and equipment, and best practices for achieving successful outcomes. By the end of this article, you will have a solid understanding of how to create custom metalwork that meets your needs and exceeds your expectations.

Section 1: Introduction to Custom Metalworking

Custom metalworking refers to the process of creating metal products by cutting, shaping, and joining metals using various tools and techniques. This process can be used to manufacture a wide range of products, including jewelry, furniture, automotive parts, architectural elements, and more. Custom metalwork requires specialized skills and knowledge, as well as access to high-quality tools and equipment. In this section, we will provide an overview of custom metalworking and discuss some of the key factors that influence its success.

Section 2: Types of Metalwork Processes

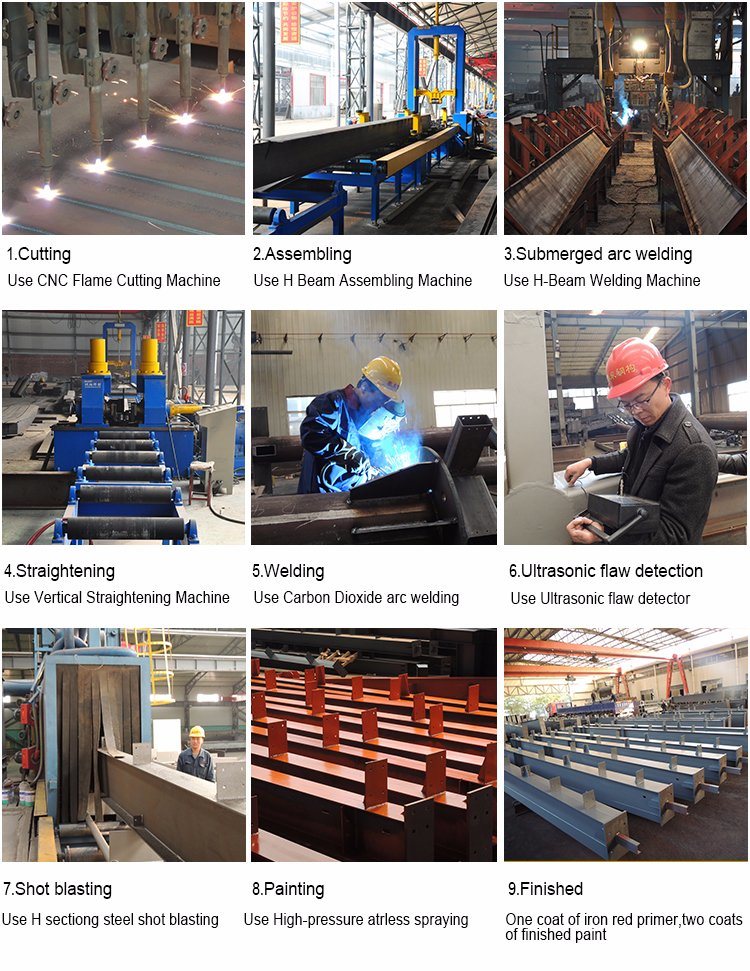

There are several common types of metalwork processes that can be used to create custom metal products. Some of the most popular include:

1. Die Cutting: Die cutting is a process in which a metal sheet is cut into precise shapes using a die. Die cutting can be done on a manual press or an automatic machine, depending on the size and complexity of the project. Die cutting is commonly used to create lettered logos, intricate designs, and other detailed shapes.

2. Sheet Bending: Sheet bending is a process in which a metal sheet is bent into shape using a set of bends or curves. Sheet bending can be done manually or with the aid of a machine, and it is commonly used to create simple shapes like circles and squares or more complex shapes like letters and numbers.

3. Laser Engraving: Laser engraving is a process in which a laser beam is used to engrave text or images into a metal surface. Laser engraving can be done on both small and large scales, and it is commonly used to add decorative elements or functional features to metal products.

4. Welding: Welding is a process in which two or more pieces of metal are joined together using heat and pressure. Welding can be done manually or with the aid of an automatic welding machine, and it is commonly used to join metal components together or repair damaged parts.

Section 3: Tools and Equipment Required for Custom Metalworking

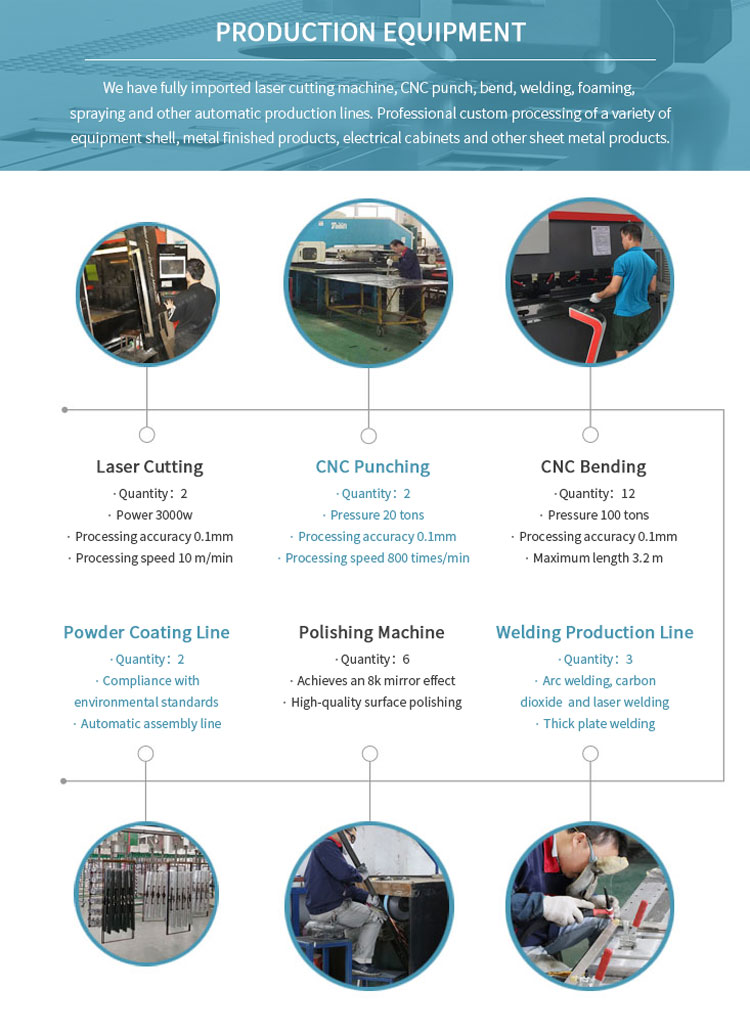

To succeed in custom metalworking, you need access to the right tools and equipment. Some of the key tools and equipment you may need include:

1. Welding torch: A welding torch is an essential tool for welding metal components together. There are various types of torches available depending on the type of welding being done (e.g. gas welding, electric arc welding).

2. Clamps: Clamps are used to hold metal sheets in place while they are being worked on. There are various types of clamps available depending on the size and shape of the material being worked on (e.g. vise grips, pliers).

3. Files: Files are used to smooth out rough edges or remove burrs from metal surfaces. There are various types of files available depending on the type of material being worked on (e.g. round files, triangular files).

4. Power drill: A power drill is an essential tool for drilling holes in metal surfaces. There are various types of drills available depending on the size and depth of the hole being drilled (e.g. hammer drill, impact drill).

Section 4: Best Practices for Successful Custom Metalworking

To ensure that your custom metalworking projects are successful, there are several best practices you should follow:

1. Plan ahead: Before starting any custom metalworking project, take the time to plan out the steps involved in creating the final product. This will help you avoid making mistakes and ensure that you have all the necessary materials and tools on hand when you start working.

2. Use quality materials: When working with metal components, it is important to use high-quality materials that are suitable for your intended purpose. This will help ensure that your finished product is durable and long-lasting.

3. Follow safety guidelines: Custom metalworking can be dangerous if proper safety precautions are not taken. Always wear protective gear such as gloves, goggles, and earplugs when working with hot metal or sharp tools. Additionally, make sure that your work area is properly ventilated to prevent inhalation of hazardous fumes.

Articles related to the knowledge points of this article:

Title: The rise of customized layered boards and hardware in interior design

Customized Hardware Enclosure for Your Unique Needs

Custom Hardware Components: The Essence of Quality and Performance

Custom Hardware Product Images: A Guide to Showcase Your Unique Design