Title: Customization of Metal Parts and Accessories Series: An Evolution in Industrial Manufacturing

The customization of metal parts and accessories has revolutionized the industrial manufacturing industry. With advanced technologies and software solutions, manufacturers can now produce highly customized products to meet specific customer requirements. This has led to increased efficiency, reduced costs, and improved customer satisfaction in the production process.In addition, customization allows for greater flexibility in product design and development, enabling companies to differentiate themselves from their competitors in the market. By offering unique and customized products, businesses can increase their brand value and attract more customers.However, customization also poses challenges for manufacturers, such as increased complexity in production processes and the need for specialized skills and resources. As a result, many companies have invested heavily in training their workforce and upgrading their equipment to cope with the demands of customized manufacturing.Despite these challenges, the trend towards customization is expected to continue in the coming years, as companies seek to remain competitive in a rapidly changing market. As such, it is crucial for businesses to embrace this trend and adapt their operations accordingly to take advantage of the opportunities presented by customization in industrial manufacturing.

In the realm of industrial manufacturing, metal parts and accessories are fundamental components that drive the success of numerous industries. From automotive to aerospace, their significance cannot be overstated. However, with the constant changes in technology and consumer demands, standard metal components often fall short in terms of functionality, aesthetics, and cost-efficiency. This is where customization comes into play.

Customizing metal parts and accessories series not only enhances product functionality but also allows manufacturers to cater to specific market needs. It presents a unique opportunity for businesses to differentiate themselves from competitors and establish a strong brand identity. In this article, we will delve into the intricacies of customization, exploring its benefits and challenges, as well as some best practices for successful implementation.

One of the primary advantages of customizing metal parts and accessories is the ability to create a one-of-a-kind product that meets specific requirements. By incorporating tailored design elements, manufacturers can enhance the product's durability, functionality, and aesthetic appeal, ultimately increasing customer satisfaction and loyalty. Furthermore, customization enables businesses to optimize their supply chain management by reducing lead times and inventory costs associated with producing standardized products. This leads to increased efficiency and profitability for both the manufacturer and the end-user.

Another significant benefit of customizing metal parts and accessories is the opportunity to explore new markets. By offering customized products, businesses can tap into niche markets that may have been overlooked due to lack of standard products. For instance, a manufacturer specializing in customized motorcycle parts can target the growing number of enthusiasts who value unique designs and personalized experiences. This not only expands the business's customer base but also opens up new revenue streams.

However, customization is not without its challenges. One of the most pressing issues is ensuring consistent quality across all custom orders. Custom production involves a high degree of flexibility, making it difficult to maintain strict quality standards. To overcome this challenge, manufacturers must implement stringent quality control measures throughout the entire process, from design to final delivery. Additionally, customization requires a significant investment in technology and equipment, which can be a barrier for smaller businesses or those operating on limited budgets. Therefore, it is crucial for manufacturers to carefully assess the feasibility of customization before committing to it.

To successfully implement customization in metal parts and accessories series, businesses must adopt a strategic approach. The following best practices can help ensure a smooth and profitable customization journey:

Conduct thorough market research: Understanding customer preferences, market trends, and competitor strategies is essential for developing effective customization solutions.

Develop clear communication channels: Clear communication with customers is critical for ensuring understanding of their requirements and expectations. It is also essential for coordinating with the production team during the customization process.

Implement quality control measures: Maintaining consistent quality across all custom orders requires a comprehensive quality control plan that includes regular inspections, testing, and feedback loops between customers and manufacturers.

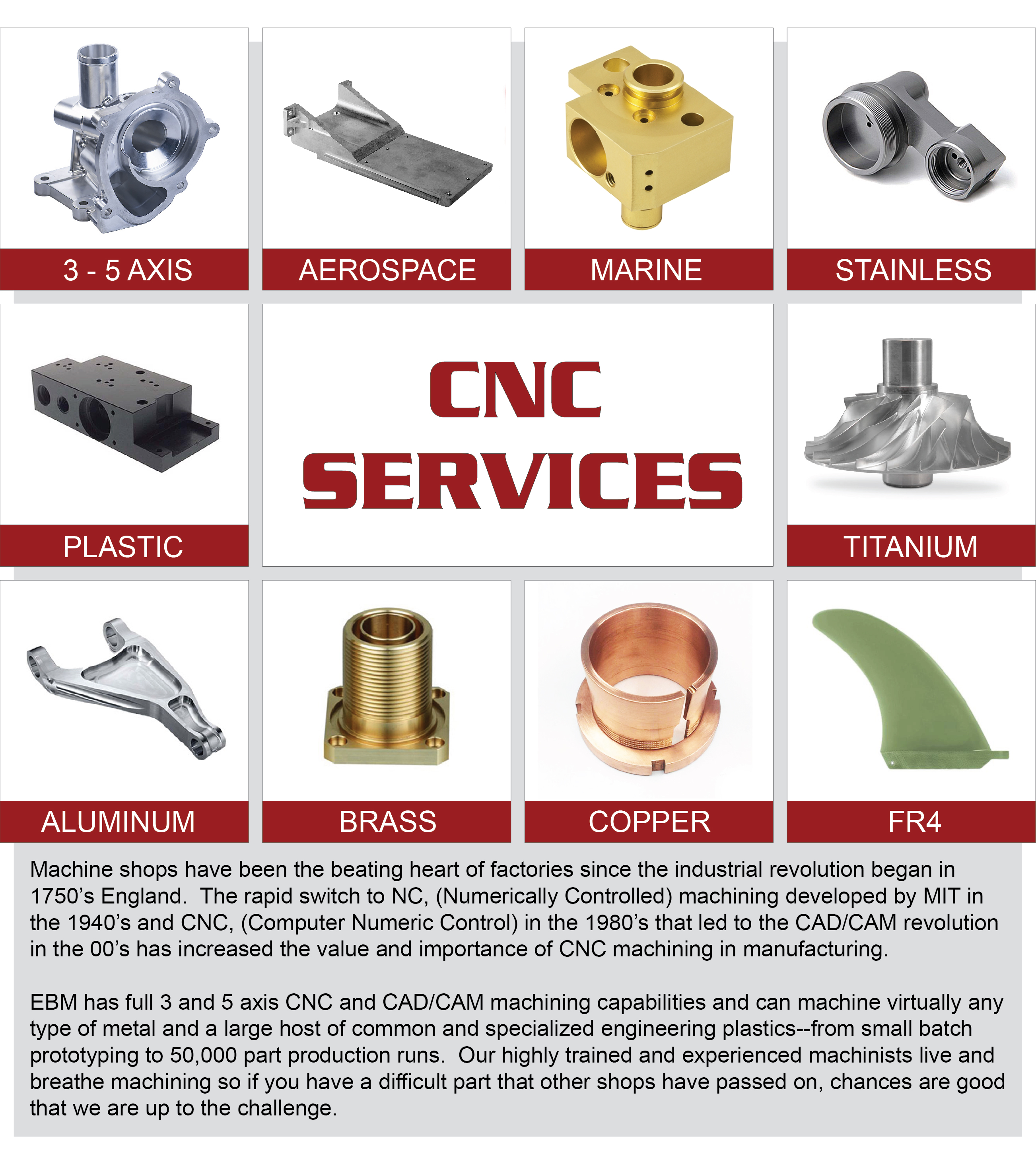

Embrace technology: Technology plays a vital role in streamlining the customization process, from design to production. Adopting advanced tools such as 3D printing or computer-aided design (CAD) software can significantly improve efficiency and reduce costs.

Foster a culture of innovation: Encouraging innovation within the organization can drive creativity and lead to the development of novel custom solutions that meet evolving customer needs.

In conclusion, customization of metal parts and accessories series represents a valuable opportunity for manufacturers to enhance their competitiveness and profitability while catering to specific market needs. While it presents certain challenges, adopting a strategic approach and implementing best practices can help businesses successfully navigate this complex landscape. As the demand for customized products continues to grow, customization will undoubtedly become an increasingly important aspect of industrial manufacturing in the years to come.

Articles related to the knowledge points of this article:

Custom Cabinet Hardware Brands: A Comprehensive Guide

Title: Customized Hardware Solutions for Home Decoration: Enhancing the Modern Lifestyle

Miyun Hardware Customization Factory: Quality Customization for All Your Hardware Needs

Title: Customized General Doors and Windows Hardware Processing: A Comprehensive Guide

Title: Customization of Hardware Luggage and Bag Locks: A Professional Approach

Title: Crafting Custom Metal Products: The Art and Science of Bag and Trunk Hardware Manufacturer