Title: Innovative Solutions in Hardware Cutting: Customized Tooling for Shenzhen Manufacturing Industry

As the manufacturing industry in Shenzhen continues to expand and evolve, there is a growing need for innovative solutions in hardware cutting. One such solution is customized tooling, which allows manufacturers to optimize their processes and improve efficiency. By working closely with companies in the Shenzhen manufacturing sector, we have developed specialized tools that are tailored to meet the unique needs of each business. Our team of experts has extensive experience in designing and producing high-quality custom cutting tools, including CNC milling machines, plasma cutters, and water jet cutters. With our state-of-the-art technology and commitment to excellence, we are able to offer fast turnaround times and competitive pricing for all of our custom cutting solutions. Whether you are a small startup or a large corporation, we are confident that we can help you achieve your goals and take your manufacturing capabilities to the next level. Contact us today to learn more about how our customized cutting tools can benefit your Shenzhen based business.

Shenzhen, a thriving metropolis in southern China, is renowned for its technological prowess and innovative spirit. As one of the leading manufacturing hubs in the country, Shenzhen has a diverse range of industries, including electronics, textiles, and machinery. In this context, precision cutting plays a crucial role in ensuring quality, efficiency, and profitability. To meet the demanding needs of the Shenzhen manufacturing industry, our company offers high-quality customized metalworking tools, particularly in the field of hardware cutting.

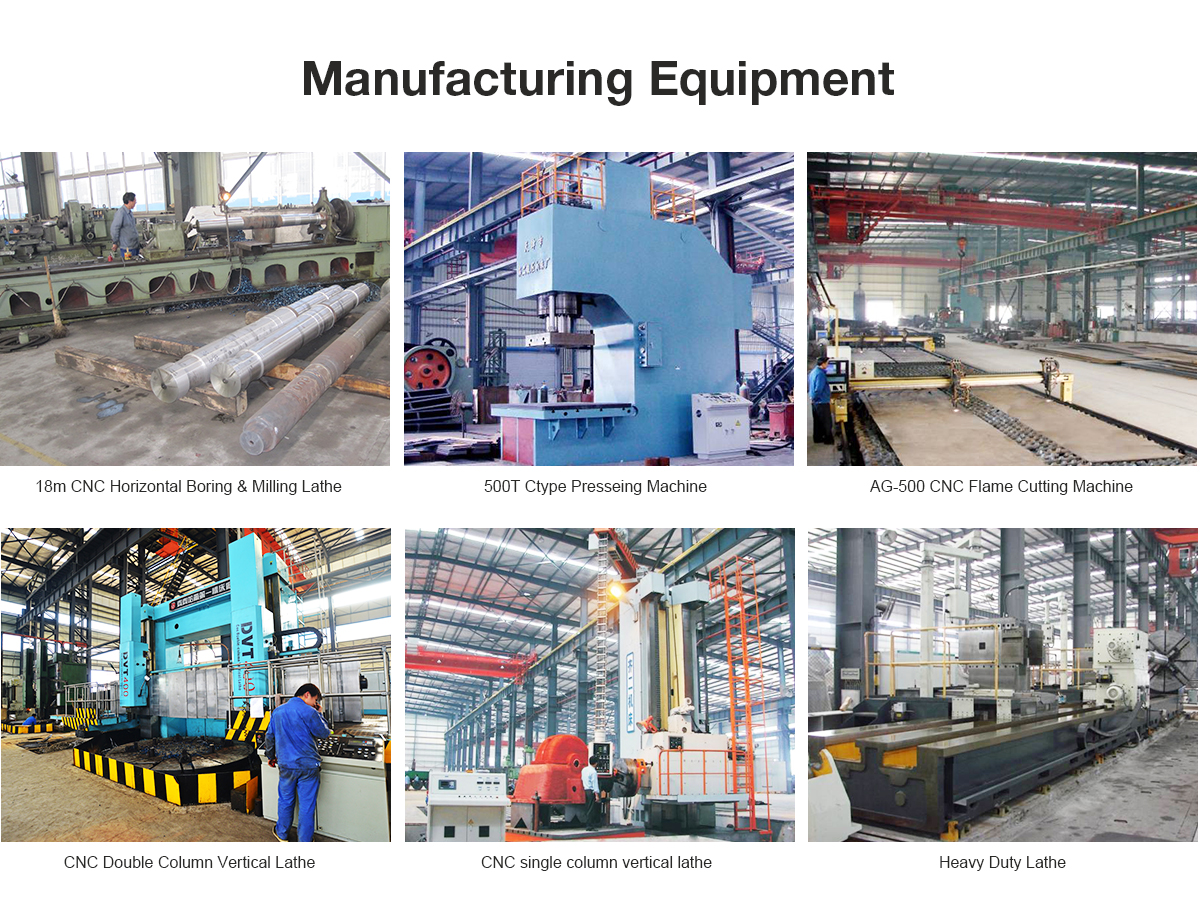

At our state-of-the-art facility, we employ advanced technologies and cutting-edge equipment to produce a comprehensive range of metal cutting tools. Our team of experienced engineers and technicians ensures that every tool meets the highest standards of quality, durability, and performance. By providing customized solutions, we can cater to the unique requirements of individual clients and help them achieve their production goals more effectively.

One of our key services is the customization of metal cutting knives and other specialized tools. Based on the client's specific needs, we offer various designs, shapes, sizes, and materials to ensure optimal results. Our cutting tools are designed to handle a wide range of metals, including steel, stainless steel, aluminum, and plastics. We use only premium grade materials to ensure longevity, stability, and safety during use. Moreover, we provide regular maintenance and repair services to ensure that our tools remain in top condition at all times.

In addition to custom knife designs, we also offer a variety of other hardware cutting solutions tailored to the Shenzhen market. For example, we provide laser cutting services, which enable precise cuts with minimal material waste. Laser cutting technology utilizes intense beams of light to cut through various materials, including metal, glass, and plastic. This method provides fast turnaround times, high accuracy, and minimal distortion compared to traditional cutting methods. We can design and manufacture laser cutters to suit specific client requirements and deliver high-quality cuts consistently.

Furthermore, our company offers sheet metal bending services to transform flat sheets into complex shapes and structures. Bending techniques such as press brake, shearing, and crimping are used to form metal parts with intricate details. We have invested in advanced equipment such as automatic bending machines and computer numerical control (CNC) benders to ensure precise and efficient production. Our team of skilled operators can work with a wide range of metals to produce a variety of bend forms, such as tee joints, corner bends, and spiral bends. This service is particularly useful for manufacturers who require custom metal components with complex geometries or unique features.

To further enhance our offerings and meet the evolving needs of the Shenzhen market, we continuously research and develop new technologies and processes. For example, we are exploring the application of 3D printing technology in the manufacturing industry. 3D printing allows for rapid prototyping and production of customized components with reduced lead time and cost. By integrating this technology into our existing processes, we can offer even more value-added services to our clients and stay ahead in the competitive Shenzhen market.

In conclusion, by offering customized solutions in hardware cutting, our company can support the growth of the Shenzhen manufacturing industry. Our expertise in cutting knives, laser cutting, sheet metal bending, and other related services enables us to provide tailored solutions that meet the specific needs of individual clients. We are committed to delivering high-quality products and services that enhance productivity, efficiency, and profitability for our customers. With our innovative solutions and commitment to excellence, we look forward to continuing to play a vital role in the development of the Shenzhen manufacturing sector.

Articles related to the knowledge points of this article:

Wholesale Custom-made Boards and Hardware for Your Home

Title: Customizing Metal Products in Foshan: A Comprehensive Guide to Quality and Accuracy

Cangzhou Hardware Shell Customization

Title: Unleashing the Power of Custom-Made Hardware in Full House Customization