The Classification and Identification of Hardware Fittings

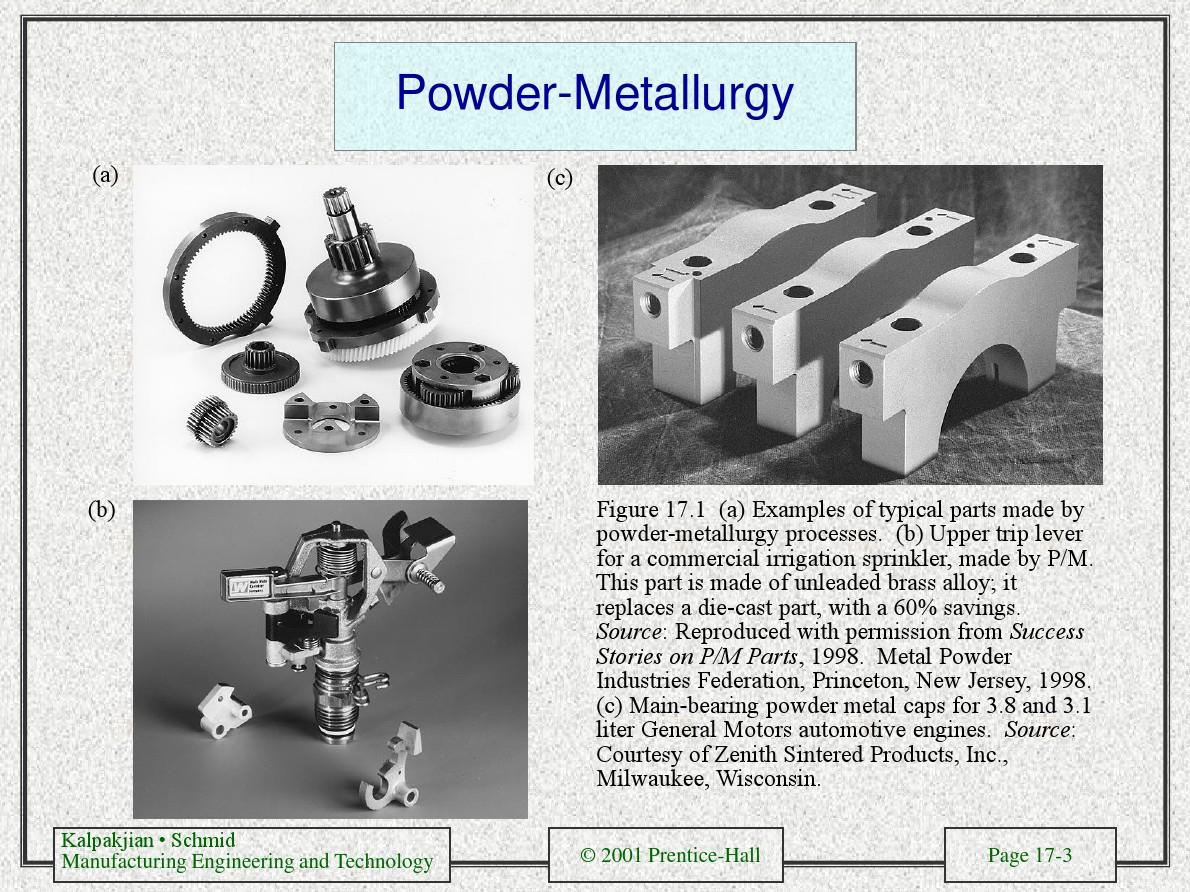

This paper presents the classification and identification of hardware fittings, which are important components in mechanical engineering. The hardware fittings are classified into several categories, including pipes fittings, valve fittings, and pump fittings. Each category has its own identification system to ensure accurate selection and installation. The identification system typically includes the type, size, material, and pressure rating of the fitting. By understanding these classifications and identification systems, engineers can select the correct hardware fittings for their mechanical systems, which will ensure efficient and reliable operation.

In the field of manufacturing, hardware fittings play a crucial role in connecting, supporting, and securing various components. These fittings are essential for the smooth operation and longevity of machines, equipment, and structures. To ensure efficient management and maintenance, it is essential to classify and identify these hardware fittings properly. This article will explore the various types of hardware fittings, their identification methods, and the importance of proper classification.

Hardware Fitting Types

Hardware fittings can be broadly classified into several categories based on their function and application. Some common types include:

1、Bolts and Nuts: These are fasteners used to secure two or more components together. Bolts have a threaded shaft that passes through holes in the components to be joined, while nuts are threaded fasteners that mate with bolts to tighten the connection.

2、Screws: Screws are fasteners with a helical thread that is used to fix components to a surface or to secure two components together. They are commonly used in woodworking, electronics, and many other industries.

3、Washers: Washers are thin, usually round or slightly elongated metal disks that are placed between bolts or screws and the surfaces being joined to distribute the pressure evenly and prevent leakage.

4、Bearings: Bearings are components that support rotating shafts in various machines and equipment. They reduce friction and wear between moving parts, allowing for smooth and efficient operation.

5、Gaskets: Gaskets are thin, usually circular or rectangular, sheets of soft material that are placed between two surfaces to seal them against leakage. They are commonly used in plumbing, automotive, and other industries.

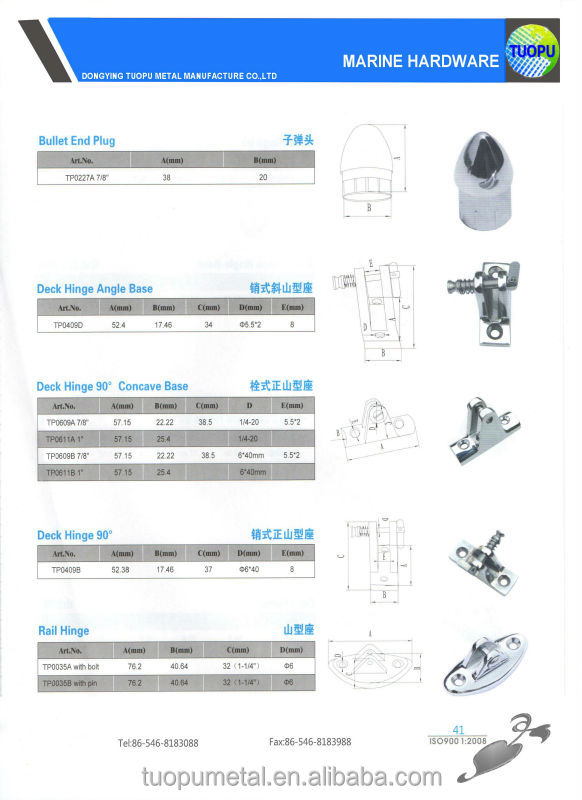

6、Pipes and Tubes: Pipes and tubes are hollow cylindrical components used to convey fluids or gases. They are classified based on their material, size, and shape.

7、Flanges: Flanges are disks or rings that are attached to the end of pipes or tube systems to facilitate connection to other components or systems. They are commonly used in plumbing, HVAC, and other industries.

8、Valves: Valves are devices that control the flow of fluids or gases through pipes or tube systems. They can be classified based on their type of action (e.g., on/off, regulating), material, and application.

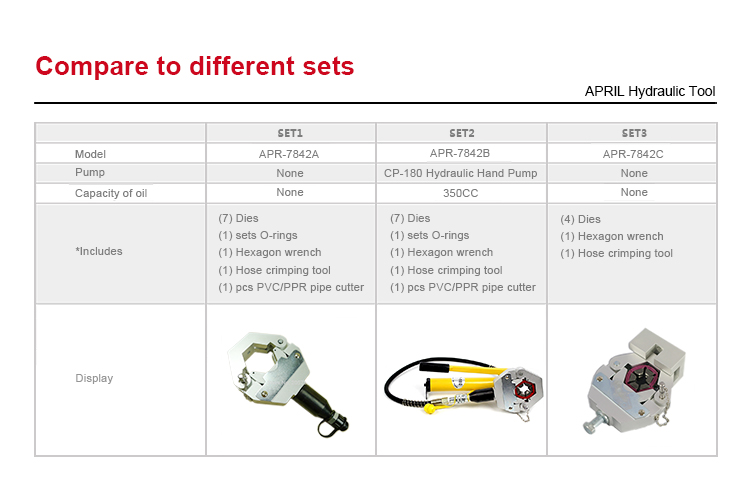

9、Pumps: Pumps are devices that convert rotational motion into linear motion to move fluids or gases from one place to another. They are commonly used in water supply, irrigation, and industrial processes.

10、Springs: Springs are resilient components made of metal wire or flat strips that store mechanical energy and release it slowly to cushion impacts or provide support for moving parts.

Identification Methods

Proper identification of hardware fittings is essential for efficient management and maintenance. Some common identification methods include:

1、Using Labels or Tags: Labels or tags with identifying information such as part number, material, size, etc., can be attached to hardware fittings during manufacturing or assembly. This information can be read using labels with adhesive backing or by using taggers that print information directly on the surface of the component.

2、Using Barcodes: Barcodes can be printed on labels or directly on the surface of hardware fittings using thermal transfer printing techniques. These barcodes can then be scanned using handheld scanners or fixed-position scanners to obtain identifying information such as part number, quantity, etc.

3、Using RFID Technology: RFID (Radio Frequency Identification) technology can be used to identify hardware fittings by embedding microchips with identifying information into the components themselves. This information can then be read using an RFID reader at any point in the supply chain or during maintenance operations.

4、Using Database Systems: Database systems can be used to store detailed information about hardware fittings such as part number, material, size, manufacturer, etc. This information can then be accessed using software tools that allow for easy searching, sorting, and filtering based on various criteria such as part number, material type, etc.

Importance of Proper Classification

Proper classification of hardware fittings is crucial for several reasons:

1、Efficient Management: Classification allows for better management of inventory by facilitating organization and identification of components according to their type, material, size, etc. This results in faster searching, sorting, and retrieval during assembly and maintenance operations.

2、Improved Accuracy: Classification helps to ensure accuracy in inventory management by preventing mix-ups and cross-contamination between different types of fittings due to their distinct identification features such as color-coding or labeling with unique part numbers/serial numbers).

3、Cost Savings: Proper classification can help reduce costs by facilitating the use of standardized parts that can be sourced from reliable suppliers at lower prices while maintaining consistent quality standards across multiple assemblies/products). Additionally, it allows for better inventory control which can help reduce wasted inventory due to obsolescence or damaged parts that have been

Articles related to the knowledge points of this article:

The Sourcing of Hardware Components

Title: Technical Guidance on selling Hardware Accessories in Guangdong

Automatic Packaging Machine for Hardware Accessories

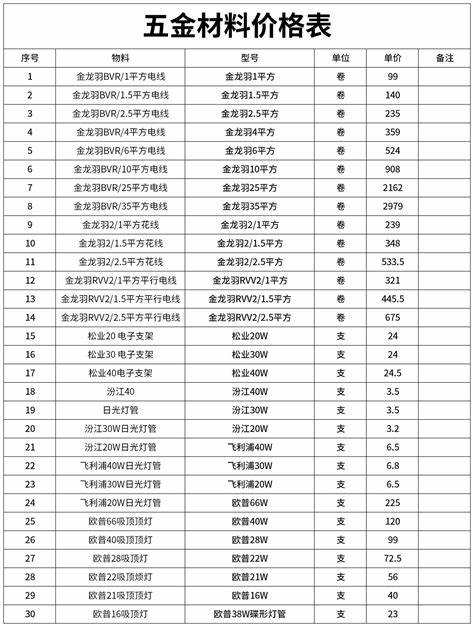

Title: Comprehensive Guide to Changsha Hardware Accessories Prices: Updated List of Best Deals