Title: WebScreen CTP Hardware Components

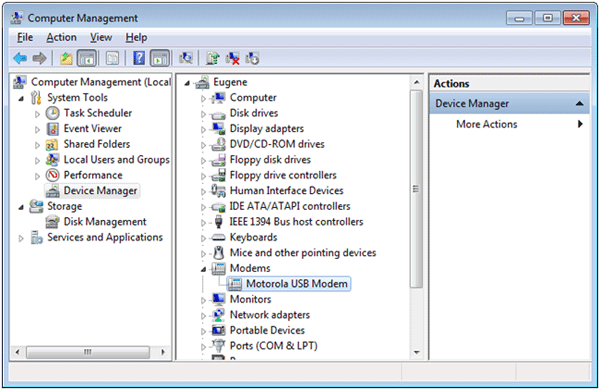

WebScreen CTP Hardware Components are the essential elements of a WebScreen CTP system. These components work together to create a stable and efficient system that can handle the demands of today's internet traffic. The hardware components of a WebScreen CTP system typically include the following: 1) a network interface card (NIC) to connect the system to the internet; 2) a central processing unit (CPU) to handle all of the data processing; 3) a memory module to store data and programs; 4) a storage device, such as a hard drive or SSD, to store large amounts of data; and 5) a display device, such as a monitor or projector, to show the output of the system. All of these components are designed to work together seamlessly, providing high performance and stability for the WebScreen CTP system.

WebScreen CTP (Continuous Tone Printing) is a high-resolution digital printing technology that is widely used in the production of photographs, maps, and other graphic materials. As the demand for high-quality prints increases, so does the demand for high-performance hardware components to support this technology. This article will explore the important role of hardware components in WebScreen CTP printing, emphasizing their construction, materials, and integration into the overall printing process.

In WebScreen CTP printing, hardware components play a crucial role. They serve as the interface between the digital image and the physical print medium, converting the former into a tangible product. This process involves several steps, including image preparation, plate making, and press operation. Each step requires a specific set of hardware components to ensure smooth and efficient printing.

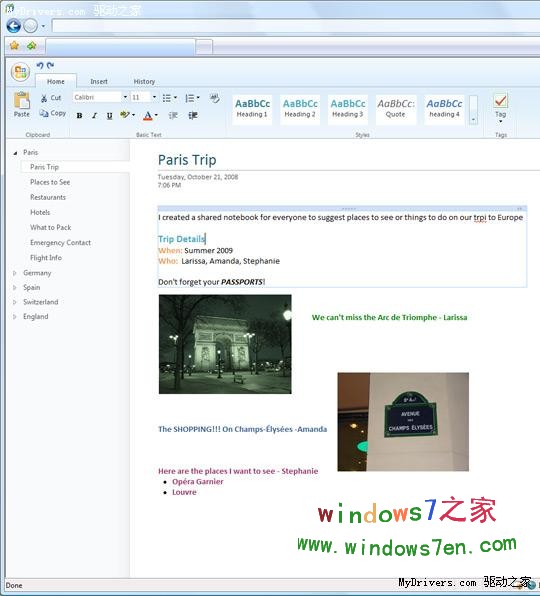

Firstly, image preparation is essential for achieving high-quality prints. This process involves converting the digital image into a format suitable for printing, adjusting its brightness, contrast, and color balance, and removing any defects or impurities. To accomplish this, WebScreen CTP printers rely on high-performance computer systems equipped with specialized software that can handle large volumes of data and complex image processing tasks. Additionally, these systems typically feature large memory capacities to store the digital images before and after processing.

Secondly, plate making is the process of transferring the processed image onto a printing plate. In WebScreen CTP printing, this is achieved using a variety of plate making machines, including offset presses, gravure presses, and flexographic presses. These machines are designed to handle different types of printing plates and provide high levels of precision and accuracy in image transfer. Additionally, they feature automated systems that can handle plate loading, unloading, and cleaning, reducing human error and improving productivity.

Thirdly, press operation involves the actual printing process. WebScreen CTP printers use high-performance printing presses that can handle large volumes of data and produce high-quality prints at high speeds. These presses are equipped with a variety of mechanical and electronic components that ensure smooth and efficient printing, including ink rollers, pressure rollers, and temperature controls. Additionally, they feature automated systems that can handle paper loading, unloading, and quality control, reducing human error and improving productivity.

The construction of hardware components in WebScreen CTP printing is crucial for achieving high performance and longevity. These components are typically made from high-quality materials that can withstand the rigors of high-speed printing and harsh chemical environments. Additionally, they are designed to be easily replaceable and maintainable to ensure smooth operation and reduce downtime.

In conclusion, hardware components in WebScreen CTP printing play a crucial role in achieving high-quality prints. By understanding their construction, materials, and integration into the overall printing process, it becomes possible to optimize their performance and ensure smooth operation. This approach can help to improve productivity, reduce human error, and enhance the overall quality of printed products.

Articles related to the knowledge points of this article:

Hardware Accessories: A Comprehensive Guide

The hardware industry in Kunming: an overview

Hardware Accessories Supermarket

Refrigerator Hardware Components

White-Gou Baggage Hardware Accessories: A Guide to Quality and Selection