Title: A Comprehensive Guide to the五金配件人工流水线

A Comprehensive Guide to the五金配件人工流水线 is a comprehensive guide that provides readers with in-depth knowledge about the production process of metal fittings through an automated assembly line. The guide covers various topics, including the types of metal fittings produced, the importance of quality control measures, and the design and layout of an efficient manufacturing facility. The guide also discusses the advantages and disadvantages of using automated assembly lines, such as increased productivity, reduced labor costs, and improved product consistency. Additionally, the guide provides insights into the latest trends and technologies used in metal fittings manufacturing, including robotic automation and artificial intelligence. Overall, A Comprehensive Guide to the五金配件人工流水线 is an essential resource for anyone interested in learning about the manufacturing process of metal fittings or looking to improve their own production processes.

Introduction

The metal industry has experienced tremendous growth in recent years, and this growth can be attributed in part to the development of efficient manufacturing processes. One such process is the use of a manual assembly line, which is commonly known as the "metal parts assembly line." This article focuses on the specific type of manual assembly line that produces metal hardware components- the metal parts assembly line for hardware. The assembly line consists of several stations where workers manually assemble metal parts into finished products. Each station has a specific task, and workers move from one station to another to complete the assembly process. In this article, we will discuss the various components of a metal parts assembly line and how they work together to produce high-quality metal hardware components.

Components of a Metal Parts Assembly Line

The metal parts assembly line for hardware typically consists of the following components:

1、Raw Materials Storage and Inventory Management System

2、Material Handling Equipment (ME)

3、Stations for Processing andassemblement

4、Quality Control Stations

5、Packaging and Shipping

6、Material Rejection and Waste Management System

7、Monitoring and Control Systems

8、Human Resources Management System (HRM)

9、Security and Safety Measures

10、Maintenance and Repair Services

Raw Materials Storage and Inventory Management System

The raw materials storage and inventory management system is responsible for receiving, storing, tracking, and managing the raw materials used in the production process. This system ensures that there is always enough raw materials available to meet the production demand and minimize wastage. The system also includes inventory tracking tools that help monitor the usage of raw materials and make adjustments when necessary.

Material Handling Equipment (ME)

Material handling equipment (ME) is used to transport raw materials, finished products, and other items within the factory premises. ME includes cranes, forklifts, conveyor belts, and other machinery that facilitate movement of heavy loads. The ME system plays a crucial role in ensuring that the production process runs smoothly by minimizing delays due to material handling issues.

Stations for Processing and Assembly

The metal parts assembly line for hardware consists of several processing and assembly stations, each with a specific task. These stations include:

a. Milling Station: The milling station is where raw metals are cut into specific sizes and shapes using milling machines. The milled pieces are then moved to the next station.

b. Drilling Station: The drilling station is where holes are drilled in the milled pieces to allow for the insertion of screws or other fasteners. The drilled pieces are then moved to the next station.

c. Welding Station: The welding station is where the milled and drilled pieces are joined together using heat and pressure. The welded pieces are then moved to the next station.

d. Painting and Coating Station: The painting and coating station is where the welded pieces are given a finish by applying paint or coatings to protect them from wear and tear. The painted and coated pieces are then moved to the next station.

e. Assembling Station: The final assembly station is where the assembled metal components are put together into finished products. This may involve adding additional features such as nuts, screws, or other hardware components. Once the final product is complete, it is moved to the packaging and shipping section.

Quality Control Stations

Quality control stations are responsible for checking the finished products for defects such as cracks, dents, or other imperfections. This helps ensure that only high-quality metal components are released into the market. Quality control stations may include visual inspection, testing using specialized instruments, or both. Any products found to be defective are rejected and sent back to the relevant station for rework or replacement.

Packaging and Shipping

Once the finished products pass quality control checks, they need to be packaged and shipped to customers. The packaging and shipping section includes machinery such as conveyor belts, cartonizers, and palletizers that help streamline the process of packaging and loading goods onto vehicles for transportation. It may also involve tasks such as labeling, documentation preparation, and customs clearance if required.

Material Rejection and Waste Management System

The material rejection and waste management system ensures that any rejected raw materials or finished products are properly handled and disposed of according to local regulations. This may involve recycling or repurposing of materials to minimize environmental impact. The system may also include tools such as shredders or compactors for reducing waste volume before disposal.

Monitoring and Control Systems

Monitoring and control systems are used to track the performance of different aspects of the metal parts assembly line For example, they may include sensors that detect when material levels in storage bins are running low, or cameras that monitor worker activity at specific stations

Articles related to the knowledge points of this article:

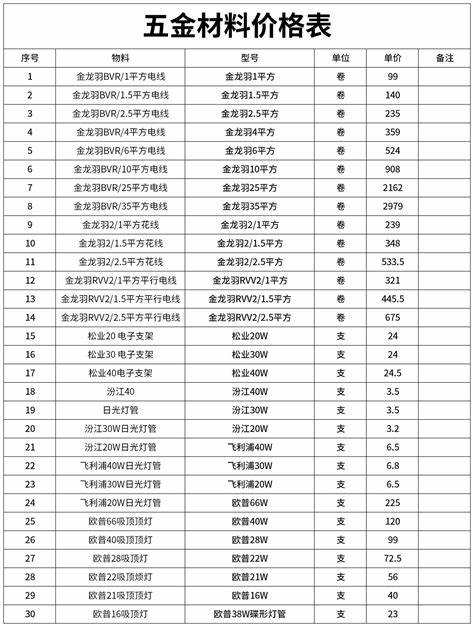

Title: Comprehensive Guide to Changsha Hardware Accessories Prices: Updated List of Best Deals

Title: Fashion Hardware Accessories: The Quintessential Guide to All Things Model

Engineering Hardware Fittings: An Essential Guide

Title: Assembly of Hardware Fittings

Title: An Analysis of the Average Price of Qualified Hardware Components in Shunyi District