The Manufacturing Process of Hardware Fittings

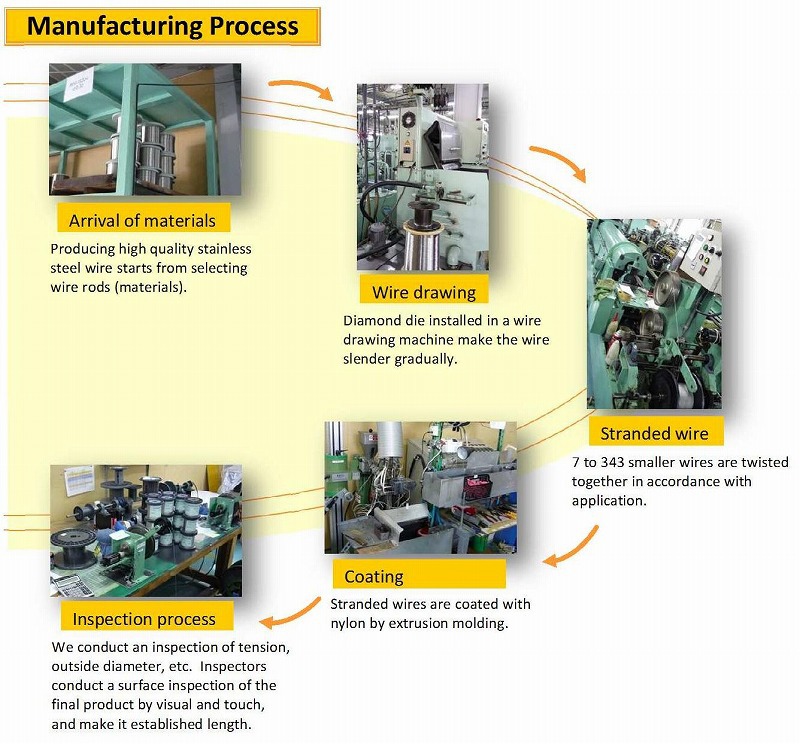

The manufacturing process of hardware fittings involves several steps to produce high-quality products. First, raw materials are selected and inspected to ensure they meet the required standards. Next, the materials are cut and shaped into the desired form using various machining techniques. Then, the pieces are deburred and polished to remove any imperfections or rough edges. Finally, the hardware fittings are inspected again to ensure they meet the specifications before being packaged and shipped to the customer. The entire process is closely monitored to ensure the quality of the products is consistently high.

Hardware fittings are essential components in various industrial and construction applications. They are made from a range of materials, including metals, plastics, and ceramics, and are used to connect, support, or protect various systems and components. In this article, we will explore the manufacturing process of hardware fittings in detail.

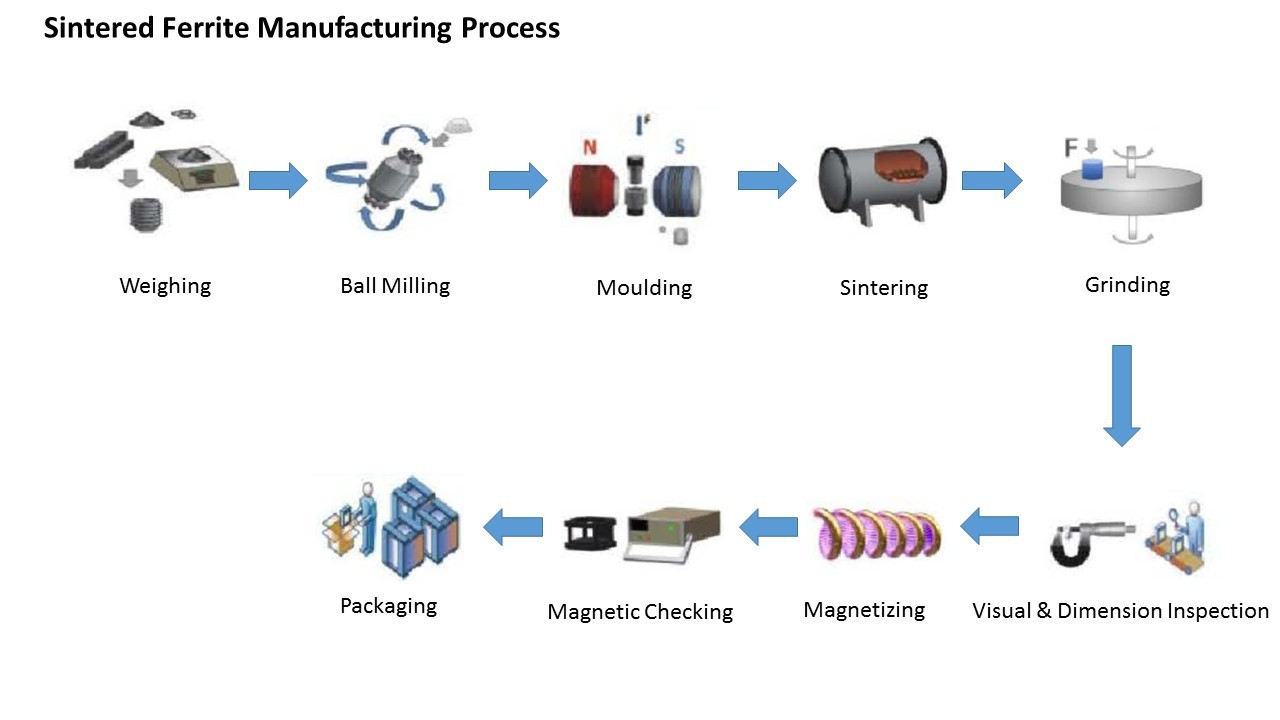

1、Material Preparation

The first step in the manufacturing process of hardware fittings is material preparation. The type of material used depends on the specific application and requirements of the fittings. For example, some fittings may be made from steel, stainless steel, aluminum, brass, or bronze. Other materials, such as plastic or ceramic, may also be used depending on the needs of the application.

Once the material is selected, it is then prepared for processing. This may involve cutting, grinding, polishing, or other similar operations to ensure that the material is ready for the next step in the manufacturing process.

2、Forming and Cutting

In this step, the prepared material is cut and formed into the desired shape of the hardware fitting. This may be done using a variety of cutting tools and techniques, such as CNC machining, laser cutting, or waterjet cutting. The choice of cutting method depends on the type of material being used and the complexity of the shape being cut.

3、Surface Treatment

After the material has been cut and formed into the desired shape, it is then subjected to surface treatment. This step involves cleaning, polishing, or coating the surface of the fitting to enhance its appearance and protect it from corrosion or other damage. Depending on the specific application and requirements of the fittings, different surface treatments may be applied to achieve the desired results.

4、Heat Treatment

In some cases, hardware fittings may undergo heat treatment to enhance their mechanical properties or improve their thermal stability. This step involves heating the fittings to a certain temperature and then cooling them down slowly to achieve the desired effect. Heat treatment can help to increase the hardness, strength, and wear resistance of the fittings while also improving their thermal conductivity and expansion properties.

5、Quality Assurance and Testing

Finally, quality assurance and testing are essential steps in the manufacturing process of hardware fittings. This step involves inspecting and testing the fittings to ensure that they meet the specified standards and requirements. Depending on the type of fitting and its intended application, different testing methods may be used to evaluate its performance and reliability. This step is crucial in ensuring that only high-quality products are released to customers.

In conclusion, the manufacturing process of hardware fittings involves several steps including material preparation, forming and cutting, surface treatment, heat treatment, and quality assurance and testing. Each step is crucial in ensuring that the final product meets the specified standards and requirements for its intended application. By understanding these steps, it becomes easier to ensure that only high-quality hardware fittings are produced for use in various industrial and construction applications.

Articles related to the knowledge points of this article:

Title:江苏绿色五金配件价格行情, A Comprehensive Analysis

Title: Hardware Fittings Business in the 21st Century

Title: Contact Person for Custom Metal Parts in Zhejiang Province

Shoe Buckle Hardware Accessories: Key Components for Shoe Production

Bed Hardware Accessories: A Comprehensive Guide

Title: Cabinet Door Hardware: An Integral Part of any Kitchen or Bathroom Design