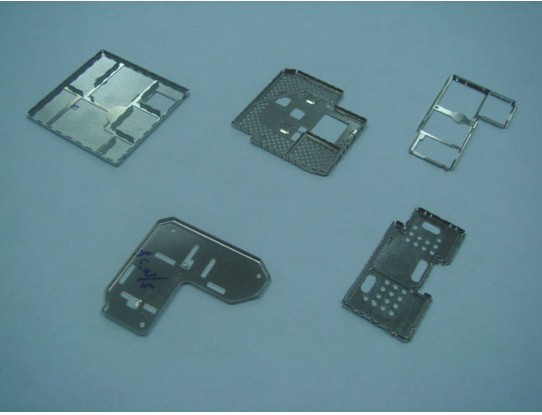

Precision Metal Parts Processing and Customization

Precision Metal Parts Processing and Customization Precision metal parts processing and customization is a crucial aspect of manufacturing, offering numerous benefits to both manufacturers and customers. By offering precision processing and customization, manufacturers can tailor their products to meet the unique needs of each customer, providing customized solutions that meet their specific requirements. This approach allows manufacturers to create products that are tailored to the individual customer, offering improved performance, efficiency, and longevity. From a customer perspective, precision metal parts processing and customization provides a high level of customization, offering a product that is tailored to their specific needs. This approach allows customers to receive a product that is designed to meet their performance requirements, improving the overall usability and reliability of the product. Additionally, precision processing and customization can help reduce cost by optimizing the design and manufacturing process, providing a more efficient and cost-effective solution. In conclusion, precision metal parts processing and customization is essential for meeting the unique needs of each customer, offering customized solutions that improve performance, efficiency, and longevity. By providing a high level of customization, manufacturers can create products that are tailored to the individual customer, offering a superior product experience.

Precision metal parts processing and customization is a crucial aspect of modern manufacturing. As technology continues to advance, the demand for precision metal parts increases, with each industry looking for ways to enhance the performance and reliability of their products. From automobiles to aerospace, precision metal parts are integral to the functioning of these complex systems. This article will explore the precision processing techniques, materials selection, and customization options available in this industry.

Precision Processing Techniques:

Precision processing techniques are essential to ensure that metal parts meet the strict specifications and tolerances required for their intended applications. Common techniques used in precision processing include cutting, grinding, and polishing. These processes can be performed using a variety of machines and tools, with each step designed to remove material and achieve the desired shape, size, and surface finish. By carefully controlling these processes, manufacturers can ensure that each part is produced to the highest standards of quality and precision.

Materials Selection:

The selection of materials used in precision metal parts processing is crucial to ensure that the final product meets the necessary performance criteria. Commonly used materials include stainless steel, aluminum, copper, and titanium. Each material has its own unique properties, such as strength, corrosion resistance, and thermal conductivity, which make them suitable for specific applications. For example, stainless steel is widely used in medical devices due to its biocompatibility and corrosion resistance, while aluminum is lightweight and suitable for aerospace applications. By understanding the properties of each material, manufacturers can make informed decisions about which material to use for their precision metal parts.

Customization Options:

Precision metal parts processing and customization offer a wide range of options to meet the specific needs of each customer. From simple to complex designs, manufacturers can produce parts with customized dimensions, shapes, and features to enhance performance or meet unique application requirements. Additionally, manufacturers can provide finishes to match specific aesthetic or functional requirements. This level of customization allows businesses to create products tailored to their specific needs, often resulting in increased performance and customer satisfaction.

In conclusion, precision metal parts processing and customization are essential to meet the demands of modern manufacturing. By understanding the precision processing techniques, materials selection, and customization options available in this industry, manufacturers can produce high-quality, precision metal parts that meet the needs of their customers. Whether it is in automobiles, aerospace, or any other industry, precision metal parts will continue to play a crucial role in advancing technology and creating products that perform at their peak.

Articles related to the knowledge points of this article:

Shenzhen Hardware Fittings: Quality and Durability for Your Projects

Title: Exploring the Art of Manufacturing Fashion Accessories in Shenyang - A Masterclass in五金配件生产

Refrigerator Hardware Components