Title: Comprehensive Guide to WUXIS Authorized Hardware Parts Processing Prices

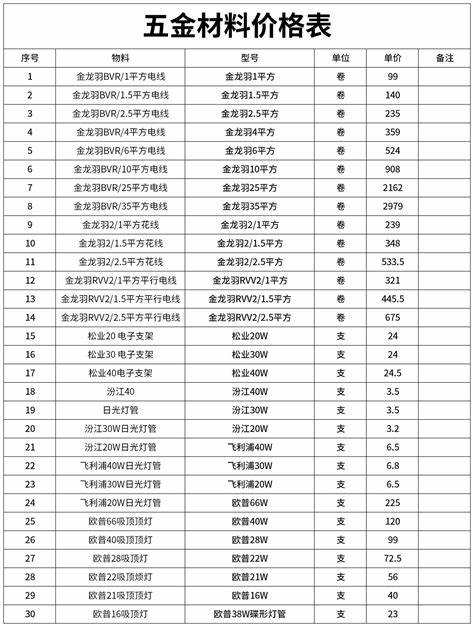

The Comprehensive Guide to WUXIS Authorized Hardware Parts Processing Prices provides a detailed analysis of the processing prices for various hardware parts authorized by WUXIS. The guide includes information on the processing methods, materials used, and processing times. It also highlights the key factors that affect the processing costs, such as raw material prices, labor costs, and production efficiency. The guide aims to help hardware businesses make informed decisions when it comes to processing their own parts or sourcing them from authorized processors. It is essential for businesses to understand the processing prices in order to optimize their operations and increase profitability. With this comprehensive guide, businesses can ensure they are getting the best possible processing prices for their hardware parts while maintaining quality and safety standards.

Wuxi, a city in the eastern region of China, is famous for its robust hardware industry. The city is home to various manufacturing units that specialize in producing high-quality hardware parts and accessories. These units offer a wide range of products, including but not limited to steel parts, metal components, plastic parts, and other related items. In this article, we will discuss Wuxi's正规五金配件加工价格, providing you with valuable information on cost factors and pricing structures.

Understanding the Cost Factors in Hardware Parts Processing

When it comes to calculating the cost of hardware parts processing, there are several essential factors to consider. These factors include material cost, labor cost, overhead expenses, and equipment maintenance costs. Let us explore each of these factors in detail.

1、Material Cost:

Material cost refers to the cost of raw materials used in manufacturing hardware parts. The price of raw materials fluctuates based on market conditions, supply and demand, and global economic trends. For instance, if the cost of iron ore increases, the production cost of steel parts will also increase. Therefore, it is crucial to keep an eye on material prices to ensure that you can maintain competitive pricing without compromising on product quality.

2、Labor Cost:

Labor cost is another critical factor in hardware parts processing. The cost of labor varies depending on factors such as experience level, skill set, and working hours. In Wuxi, wages for skilled workers tend to be higher than for unskilled workers. Additionally, labor costs may also include benefits such as insurance premiums, social security contributions, and paid leave. It is essential to factor in these costs when determining production costs and pricing strategies.

3、Overhead Expenses:

Overhead expenses refer to the ongoing costs associated with running a business, such as rent, utilities, insurance, and marketing expenses. These costs are fixed and do not vary based on production output. Therefore, they must be included in the overall cost of production to provide a more accurate estimate of the final price of hardware parts.

4、Equipment Maintenance Costs:

Hardware parts processing requires specialized equipment that must be regularly maintained to ensure optimal performance. Repairs, upgrades, and replacements can add significant costs to the production process. It is essential to budget for these expenses to prevent unexpected downtime and maintain productivity.

Pricing Strategies for Wuxi's Authorized Hardware Parts Processing Units

Once you have understood the essential factors contributing to hardware parts processing costs, you can develop effective pricing strategies to remain competitive in the market. Here are some tips to help you price your hardware parts appropriately:

1、Analyze Competitors' Pricing: Research your competitors' pricing structures and identify any gaps or opportunities in the market. This information can help you determine an appropriate price point for your products while remaining competitive.

2、Set Price Based on Material Cost: Use the latest material prices to calculate your unit costs accurately. Then, factor in your labor costs, overhead expenses, and desired profit margin to set a final price for your products.

3、Offer Discounts for Large Orders: Consider offering discounts for bulk orders or contracts with customers who require large quantities of hardware parts. This strategy can help you attract new customers and boost sales volume.

4、Provide Different Product Ranges at Different Price Points: Offering a range of hardware parts with varying degrees of complexity can help you cater to different customer needs and budgets. By providing multiple price points for similar products, you can increase your market share and attract a broader customer base.

5、Incorporate Customer Feedback: Regularly gather feedback from customers regarding your pricing strategies and adjust them accordingly to maintain competitiveness and meet their expectations.

Conclusion:

In conclusion, understanding the cost factors involved in hardware parts processing is crucial for businesses operating in Wuxi's thriving hardware industry. By keeping an eye on material prices, labor costs, overhead expenses, and equipment maintenance costs, you can develop effective pricing strategies that ensure profitability while maintaining high product standards

Articles related to the knowledge points of this article:

Suzhou Hardware Accessories: Quality and Innovation

Expansion and contraction of hardware fittings

Fenglv Hardware Fittings: Quality and Durability for Your Projects

Title: The Compositional Fundamentals of Jiangsus Giant Hardware Accessories