Customizing and Processing Bulk Orders of Hardware

When it comes to processing and customizing bulk orders of hardware, there are a number of important steps and considerations that need to be taken into account. Firstly, it is essential to have a clear understanding of the specific requirements and needs of the customer. This includes understanding the type of hardware involved, the quantities being ordered, and any specific customization requirements that may be needed to meet the customer’s needs.Once the customer’s requirements have been established, the next step is to assess the current capacity and capability of the manufacturing process to handle the order. This includes considering the available resources, such as machines, tools, and personnel, as well as the current workload and any potential bottlenecks that may affect the order’s timely completion.Once the capacity and capability have been assessed, it is then possible to develop a customized processing plan that will enable the order to be completed efficiently and effectively. This plan may include the use of specialized equipment or techniques to achieve the desired level of customization, as well as the implementation of quality control measures to ensure that the finished product meets the customer’s high standards.In conclusion, processing and customizing bulk orders of hardware requires a clear understanding of customer needs, an assessment of manufacturing capacity and capability, and the development of a customized processing plan that will enable the order to be completed efficiently and effectively. By taking these steps, manufacturers can ensure that their customers receive the high-quality, customized hardware orders that they have come to expect.

The hardware industry is one of the most lucrative and diverse sectors in the world, offering numerous opportunities for businesses to grow and thrive. One such opportunity is the practice of bulk ordering, processing, and customizing hardware products. This practice has numerous benefits that include cost efficiency, increased productivity, and the ability to tailor products to meet specific customer needs. In this article, we explore the world of hardware customization and processing from a wholesale perspective.

Firstly, the process of hardware customization involves taking standard hardware components and modifying them to meet the specific requirements of a customer. This could involve changing the shape, size, color, or even the functionality of a product. The advantage of customization is that it allows businesses to offer their customers a unique and tailored product that meets their individual needs. This can help to create a more personalized and memorable customer experience, increasing the likelihood of repeat business and customer loyalty.

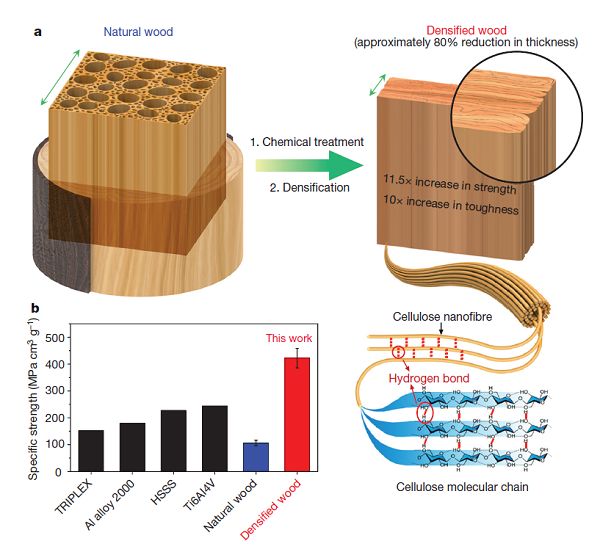

Secondly, processing bulk orders of hardware involves taking large quantities of raw materials and converting them into finished products. This process can be divided into several stages, including cutting, machining, polishing, and packaging. By processing bulk orders, businesses are able to take advantage of economies of scale, reducing the unit cost of each product and increasing overall profitability. Additionally, processing bulk orders can help to streamline operations and improve productivity, allowing businesses to meet their customer demands more efficiently.

Thirdly, combining hardware customization and bulk processing allows businesses to offer their customers a unique and cost-effective solution to their hardware needs. By understanding the specific requirements of each customer and tailor-making products to meet those needs, businesses are able to create customized solutions that are both functional and profitable. This approach not only helps to differentiate a business from its competitors but also allows it to create more meaningful relationships with its customers.

In conclusion, the practice of hardware customization and bulk processing offers numerous benefits to businesses in the hardware industry. It allows them to offer their customers unique and tailored products that meet their individual needs, process large quantities of raw materials into finished products efficiently, and create meaningful relationships with their customers. By combining these two practices, businesses are able to create cost-effective and profitable solutions to their customer’s hardware needs.

Articles related to the knowledge points of this article:

Ningbo Hardware Accessories Wholesale

Great City Hardware and Electrical Supplies Wholesale

Title: Exploring the Prosperous Jinjiang Hardware Wholesale Market