Precision Metal Stampings Wholesale Pricing Guide

The precision metal stampings industry is a highly competitive market that requires manufacturers to offer high-quality products at competitive prices. In order to succeed in this industry, it is important to have a clear understanding of the costs involved in producing these products and to be able to accurately price them based on those costs. This guide provides valuable information on how to determine the cost of precision metal stampings and how to price them effectively. It covers topics such as material costs, labor costs, equipment costs, and overhead expenses. By following the recommendations outlined in this guide, manufacturers can ensure that they are offering competitive pricing while still maintaining profitability. Whether you are a new entrant or an established player in the market, this guide will help you navigate the complexities of the precision metal stampings industry and succeed in today's challenging business environment.

Introduction to Precision Metal Stampings

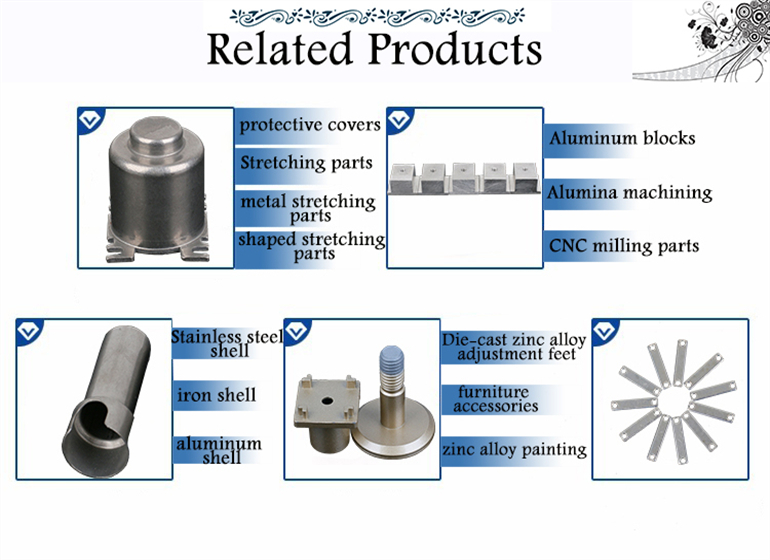

Precision metal stampings, also known as precision metal parts or precision machining parts, are fabricated components that are produced using a variety of manufacturing techniques. These components are widely used in various industries, including automotive, aerospace, medical, and consumer electronics. They are known for their high accuracy, surface finish, and durability. In this article, we will discuss the importance of precision metal stampings, their applications, and the factors that affect their cost. We will also provide a comprehensive pricing guide for precision metal stampings wholesalers and manufacturers.

The Importance of Precision Metal Stampings

Precision metal stampings play a crucial role in modern manufacturing processes due to their ability to produce complex shapes and sizes with high accuracy. They offer numerous benefits over traditional manufacturing methods, including:

1、High Accuracy: Precision metal stampings can be produced with a tolerance of up to ±0.1 mm, which is much higher than other manufacturing techniques such as casting and welding. This allows for more accurate and precise parts that meet the needs of demanding applications.

2、Efficient Manufacturing: Precision metal stampings are produced using automated equipment and specialized tools, which reduces production time and increases efficiency. This makes them ideal for mass production of high-volume parts.

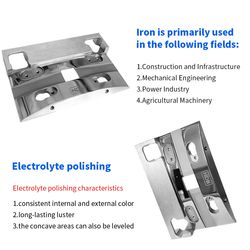

3、Versatility: Precision metal stampings can be produced using a wide range of materials, including steel, aluminum, stainless steel, and titanium. This allows manufacturers to create parts that meet specific performance and environmental requirements.

4、Cost-effective: While precision metal stampings may have a higher initial cost compared to other manufacturing methods, they are generally more cost-effective in the long run due to their high efficiency and low maintenance requirements.

Applications of Precision Metal Stampings

Precision metal stampings have a wide range of applications in various industries, including:

1、Automotive Industry: Precision metal stampings are used to manufacture components such as dashboard panels, steering wheels, and engine components. They are commonly used in automobiles, trucks, and buses due to their high strength and durability.

2、Aerospace Industry: Precision metal stampings are used to manufacture components for aerospace applications, such as airplane wings, fuselage members, and landing gear. They are designed to withstand the harsh conditions of space travel and ensure the safe operation of aircraft.

3、Medical Industry: Precision metal stampings are used to manufacture components for medical devices, such as prosthetic limbs, surgical instruments, and dental implants. They are designed to meet specific hygiene requirements and ensure patient safety.

4、Consumer Electronics: Precision metal stampings are used to manufacture components for consumer electronics, such as smartphones, tablets, and laptops. They are designed to provide a smooth user experience and ensure product durability and reliability.

Factors Affecting Precision Metal Stampings Cost

There are several factors that can influence the cost of precision metal stampings, including:

1、Material Choice: The material used to manufacture precision metal stamps can have a significant impact on the cost. Different materials have different properties and costs, so it is important to choose the right material for the specific application.

2、Design Complexity: The design complexity of the component being manufactured can also affect the cost. More complex designs require more time and effort to produce, which ultimately increases the cost.

3、Production Volume: The production volume of precision metal stamps can affect the cost by influencing the unit price of the material and labor required. Lower volumes often result in higher per-unit costs due to increased overhead expenses.

4、Raw Material Prices: The prices of raw materials used in precision metal stampings can fluctuate based on supply and demand dynamics. Changes in raw material prices can affect the overall cost of precision metal stampings production.

Pricing Guide for Precision Metal Stampings Wholesalers and Manufacturers

Given the diverse applications and factors that affect the cost of precision metal stamps, providing a comprehensive pricing guide is challenging. However, below is a general pricing guide that can be used as a starting point for wholesalers and manufacturers looking to purchase precision metal stamps:

1、Material Costs: The cost of materials used in precision metal stamps can vary depending on the material type and availability. Generally speaking, metals such as steel and aluminum tend to be less expensive than specialty metals like titanium or stainless steel. The cost of raw materials can be influenced by market conditions such as global economic trends, geopolitical tensions, and natural disasters.

2、Design Costs: The design complexity of the component being manufactured determines the amount of time and effort required to produce it accurately. More complex designs typically involve higher design costs associated with engineering, prototyping, and testing efforts. These costs can vary depending on the design software utilized by the manufacturer and the expertise of their design team.

3、Processing Costs: The processing costs associated with precision metal stamps include machine tooling setup fees, operator training fees, tooling maintenance fees, and inspection costs. These costs can vary depending on the size and sophistication of the machine tooling used by the manufacturer.

4、Labor Costs: The cost of labor is another significant factor affecting the overall cost of precision metal stamps production. Labor costs include salaries, benefits, overtime pay, training fees, and worker safety expenses. Labor costs can vary depending on factors such as location, skill level of the workers, and work ethic of the employees involved in production.

5、Overhead Costs: Overhead costs refer to the ongoing expenses associated with running a business, such as rent, utilities, insurance, accounting fees, and office supplies. These costs do not directly relate to the production of precision metal stamps but must be considered when calculating overall production costs.

Articles related to the knowledge points of this article:

Title: Jiangmen Hardware Wholesale Market: A Comprehensive Guide

Handan Hardware Lock Wholesale

Shun Da Paint & Hardware Wholesale

Exploring the World of Hardware Wholesale in Fuzhou: A Comprehensive Guide