Custom Metal模具, Understanding the Process and Benefits

Custom Metal模具是一种定制化金属制品的制造工具。这种模具通常用于生产大量的产品,例如汽车零件、电子设备、医疗器械和家用电器等。了解这些模具的制造过程和优势对于制造商来说至关重要。制造Custom Metal模具的过程非常复杂。它需要精确的设计和工程,包括材料选择、CAD绘图、加工和装配等多个步骤。为了确保模具的质量和可靠性,制造商还需要进行严格的测试和质量控制。使用Custom Metal模具也带来了许多优势。它们可以大大提高生产效率,因为它们可以一次性生产大量相同的产品。由于这些模具是定制的,它们可以根据客户的具体要求进行设计,从而实现更高的精度和更好的表面光洁度。由于模具经过多次测试和调整,因此它们的使用寿命更长,维护成本更低。了解Custom Metal模具的制造过程和优势是非常重要的,特别是对于那些需要大量生产相同产品或需要高精度和表面光洁度的制造商来说。通过正确地选择和使用这些模具,他们可以提高生产效率并降低成本。

Introduction:

The manufacturing industry relies heavily on precise, customized metal parts to meet the diverse needs of customers. One crucial aspect of this process is the use of precision metal模具, also known as custom metal molds or dies. These specialized tools are designed to shape metal materials into a wide range of shapes and sizes, ensuring that the final product meets exact specifications. In this article, we will explore what custom metal模具 are, their purpose, the process involved in creating them, and the benefits they offer to manufacturers.

What are Custom Metal模具?

Custom metal模具 refer to high-precision tools used in the manufacturing industry for shaping and forming metal materials into various shapes and sizes. These tools are typically made of hardened steel, aluminum, or other durable materials that can withstand the high temperatures and pressure involved in the molding process. The primary purpose of custom metal模具 is to create precise, consistent products with minimal waste, which improves efficiency and reduces costs for manufacturers.

The Process of Creating Custom Metal模具

The process of creating custom metal模具 involves several steps, starting from the design phase to the final production. Here is a brief overview of each stage:

1、Design: The first step in creating custom metal模具 is to design the tool. This involves determining the type of material, size, and shape of the final product, as well as any special features or requirements. The design is created using computer-aided design (CAD) software, which allows designers to create detailed models of the tool before it is fabricated.

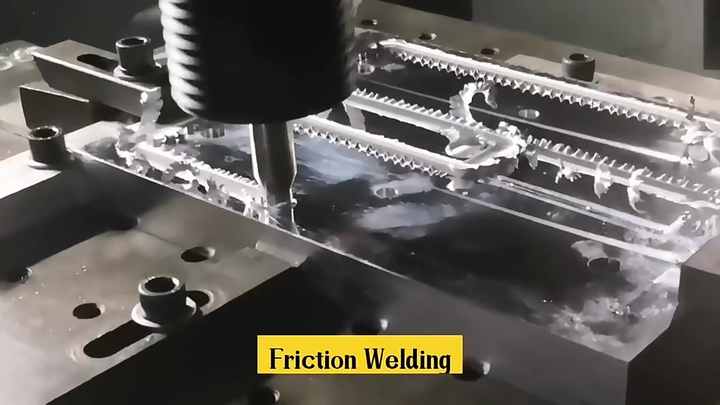

2、Fabrication: Once the design is finalized, the next step is to fabricate the tool. This involves cutting and shaping the material using specialized equipment such as lathes, mills, and routers. The fabrication process may take several days or weeks depending on the complexity of the tool and the quality standards required.

3、Testing: After the tool has been fabricated, it is tested to ensure that it meets the specified requirements. This involves measuring its accuracy, surface finish, and other important characteristics. Any defects or flaws found during testing are addressed and resolved before the tool goes into production.

4、Production: Finally, the custom metal模具 is ready for production. During this stage, the tool is used to shape metal materials into the desired shape and size. The process may involve multiple iterations to fine-tune the tool and achieve optimal results.

Benefits of Custom Metal模具

There are several benefits of using custom metal模具 in manufacturing processes. Some of these benefits include:

1、Improved Quality: Custom metal模具 allow manufacturers to produce products with precise dimensions, uniform surfaces, and tight tolerances. This ensures that the final product meets exact specifications and exceeds customer expectations.

2、Increased Efficiency: By eliminating waste and reducing production time, custom metal模具 improve efficiency in manufacturing processes. This translates into reduced costs for manufacturers and faster turnaround times for customers.

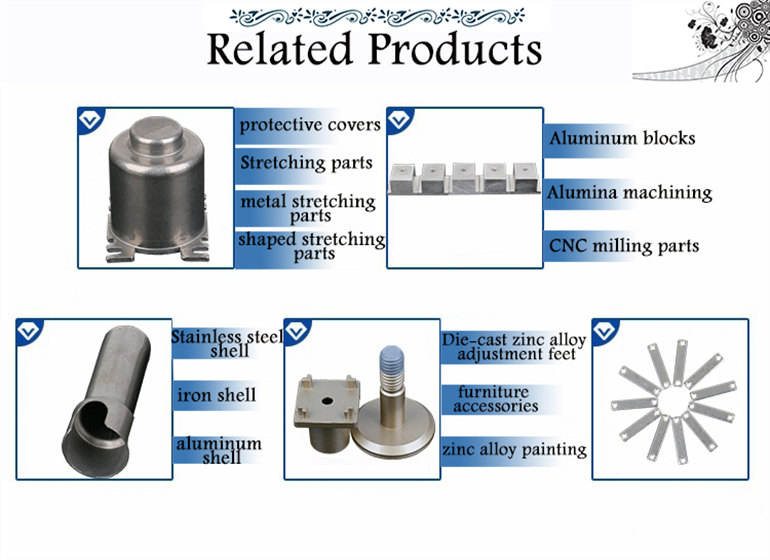

3、Versatility: Custom metal模具 can be used to shape a wide range of metal materials, including aluminum, steel, copper, and brass. This makes them ideal for producing a variety of products, from small intricate parts to large-scale industrial components.

4、Reduced Material Costs: By shaping metal materials into precise forms, custom metal模具 help reduce material wastage and improve material utilization rates. This translates into lower material costs for manufacturers and improved profitability for their businesses.

Conclusion:

In conclusion, custom metal模具 play a vital role in modern manufacturing processes by enabling manufacturers to produce products with precision, consistency, and low waste. From their precise designs to their efficient production processes, custom metal模具 offer numerous benefits to manufacturers looking to improve their productivity and competitiveness in today's fast-paced business environment. As such, understanding how custom metal模具 work and investing in quality designs and fabrication processes can help manufacturers stay ahead of the curve and deliver exceptional value to their customers.

Articles related to the knowledge points of this article:

Custom Furniture Hardware Order

Wholesale Custom-made Boards and Hardware for Your Home

Custom Hardware Manufacturers in Linyi

Custom Metal Furniture Processing: A Comprehensive Guide

Title: Special Prices on Custom Hardware in Yangzhou

Title: Exploring the World of Beibei Districts Bulk Hardware Manufacturing