The Art and Craft of Machine Case Hardware Assembly and Repair

The Art and Craft of Machine Case Hardware Assembly and Repair involves the skilled manipulation of various components to ensure that a machine's case is assembled and repaired properly. It requires precision and attention to detail, as even small mistakes can have significant consequences for the functionality and longevity of the machine. The process involves cleaning and preparing the case, selecting and attaching hardware components such as screws, brackets, and bolts, and ensuring that all parts are in proper alignment. Additionally, it may involve troubleshooting and repairing any issues that arise during the assembly or repair process. The art of Machine Case Hardware Assembly and Repair requires not only technical skills but also creativity and problem-solving abilities. By combining these skills with a deep understanding of the machinery being worked on, technicians can ensure that their work is not only efficient and effective but also aesthetically pleasing and long-lasting.

In the world of computer hardware, the machine case is often overlooked as merely a functional container for the intricate workings of a machine. However, this tiny but crucial component plays a pivotal role in the stability, longevity, and efficiency of any computer system. At the heart of this essential component is the hardware assembly and repair process, which involves the meticulous machining, fitting, and testing of metal parts to ensure optimal performance and durability. This article delves into the intricacies of machine case hardware assembly and repair, exploring the various steps involved, the importance of quality control measures, and the role of advanced technologies in this complex process.

Machine Case Hardware Assembly: A Comprehensive Guide

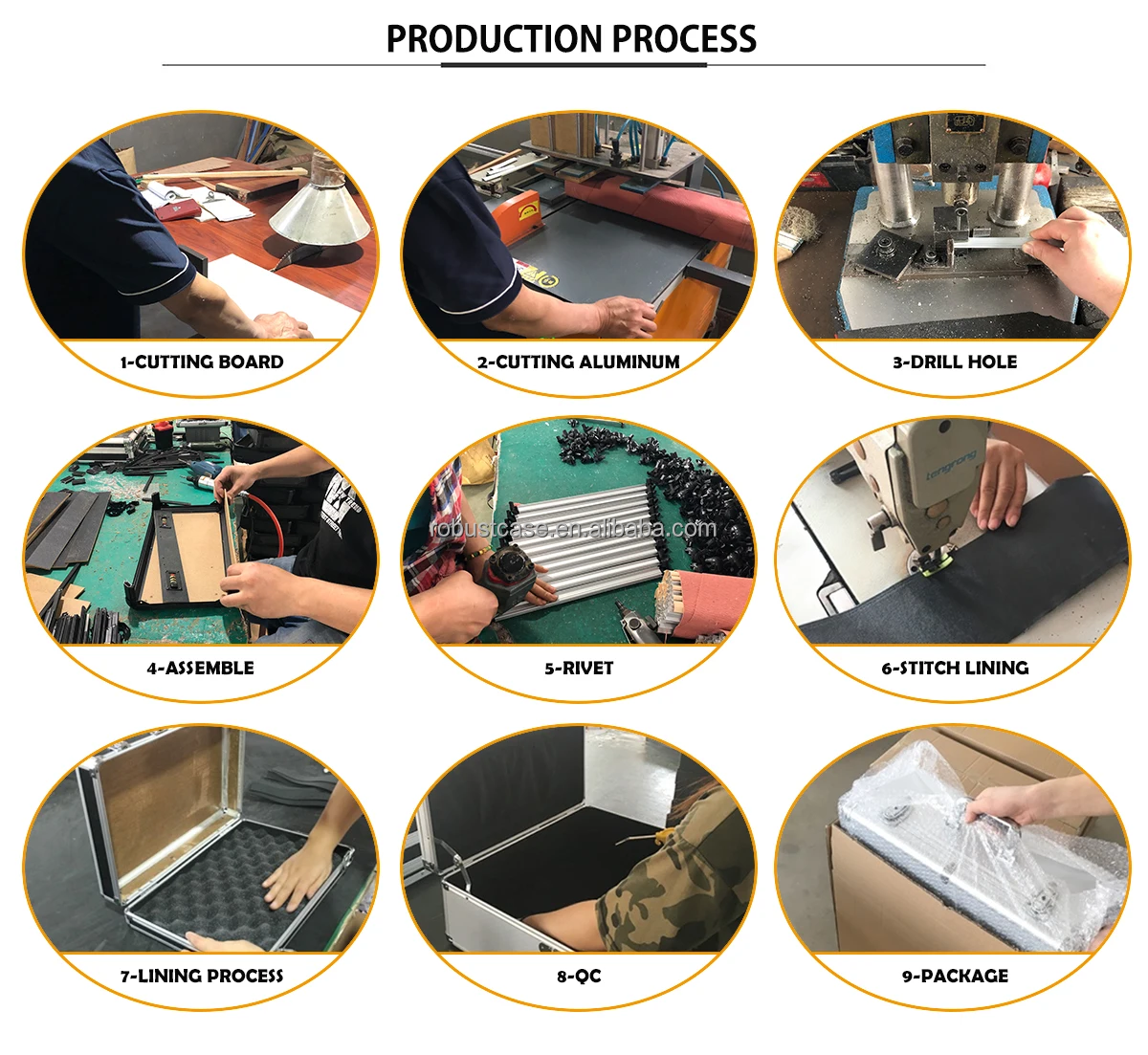

At its core, machine case hardware assembly involves the precise positioning and attachment of numerous small metal parts to form a cohesive whole. This task requires a high level of technical skill and attention to detail, as even the smallest error can lead to significant problems down the line. The first step in assembly is the cleaning and preparation of the parts, which may include sanding, polishing, or other surface treatments to ensure a smooth and secure fit. Next, the parts are carefully positioned and attached using specialized tools, such as screwdrivers, pliers, and wrenches. Once all the parts have been assembled, the machine case is tested to ensure that all components are securely fastened and that there are no leaks or other issues.

Quality Control Measures: Ensuring Consistent Performance and Reliability

Despite the complexity of the machine case hardware assembly process, there are several key factors that can affect the overall quality of the finished product. These include the materials used, the precision of the manufacturing process, and the effectiveness of quality control measures. To ensure consistent performance and reliability, it is essential to use high-quality metals such as stainless steel or aluminum for all components. Additionally, advanced manufacturing techniques such as CNC (computer numerical control) machining can help to maintain precision and consistency throughout the assembly process. Finally, rigorous quality control measures such as visual inspections, stress testing, and performance evaluations are critical to identifying and addressing any issues before they can cause problems down the line.

The Role of Advanced Technologies in Machine Case Hardware Assembly: A Look into Modern Solutions

As technology continues to advance at an unprecedented pace, so too do the methods and tools used in machine case hardware assembly. From 3D printing to robotic automation, new technologies are revolutionizing the way that metal parts are manufactured, assembled, and repaired. One promising area of development is the use of additive manufacturing (AM), which involves creating metal parts layer by layer using a digital file. This method offers several advantages over traditional methods, including faster turnaround times, reduced waste, and greater flexibility in design. Another exciting development is the use of robotics in assembly processes, where robots can perform repetitive tasks with incredible speed and accuracy. This not only increases efficiency but also reduces the risk of human error, leading to higher-quality results.

Conclusion: A Bright Future for Machine Case Hardware Assembly and Repair

As computers become increasingly complex and sophisticated, the need for reliable and efficient machine case hardware assembly and repair has never been more important. By embracing cutting-edge technologies and adhering to strict quality control standards, manufacturers can ensure that their products meet the highest levels of performance and durability. Whether through advanced manufacturing techniques like AM or automated assembly processes using robots, the future of machine case hardware assembly looks bright indeed. As we continue to push the boundaries of what is possible in computing technology, it is clear that the humble machine case will remain an essentialcomponent in this ever-evolving landscape.

Articles related to the knowledge points of this article:

Pull Basket Hardware Accessories: An Essential Guide

Title: Comprehensive JIAZHANG NUCLEOGENIC POWER PLANT HARDWARE ACCESSORIES PRICE LIST

Title: Promotion of Metal Hardware Components and Materials in Hongkou District

Title: Understanding the Market Prices of Automatic Hardware Accessories in Hubei Province