The Art of CNC Plasma Cutting in Metal Fabrication

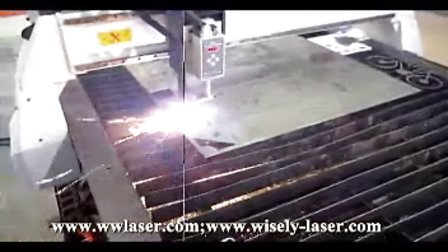

CNC plasma cutting is a precision metalworking technique that involves the use of a high-temperature plasma torch to cut through metal sheets. This method is commonly used in metal fabrication for a variety of applications, from industrial manufacturing to architectural projects. The process begins by programming the CNC machine to move along the desired path and then igniting the plasma torch at the appropriate speed and angle. The heat generated by the plasma torch melts the metal, creating an intense jet of flame that cuts through the material with incredible accuracy and speed. The resulting cuts are often smooth and precise, with minimal distortion or burrs. However, CNC plasma cutting requires a high level of skill and experience to operate effectively. To ensure optimal results, it is important to carefully program the machine and maintain proper safety precautions during operation. Despite its complexity, CNC plasma cutting is a powerful tool for fabricators looking to achieve precision cuts in metalwork. By harnessing the power of modern technology and skilled craftsmanship, this technique allows manufacturers to create complex designs and intricate patterns that would be difficult or impossible to achieve using traditional methods. As such, CNC plasma cutting remains an essential tool for metalworkers seeking to push the limits of what is possible in the world of precision metalwork.

As the world continues to evolve at an unprecedented pace, so does the technology that powers it. One field in particular, that has been rapidly advancing in recent years is precision cutting. In this context, the term 'CNC plasma cutting' has become a common phrase in metal fabrication. CNC stands for Computer Numerical Control, while plasma cutting is a technique that utilizes an electric current to cut through metal. This process offers incredible accuracy and efficiency, making it a popular choice among manufacturers across various industries.

At the forefront of this revolution is a select group of companies dedicated to manufacturing high-quality CNC plasma cutting tools and systems for various metal products. These businesses understand the intricate details involved in cutting different metals, and have developed advanced techniques to optimize their products. They are the experts we refer to as 'CNC plasma cutting五金厂家'.

These companies operate using state-of-the-art machinery, which they regularly upgrade to stay ahead of the curve. Their skilled technicians and engineers are continuously working on improving these cutting systems, ensuring optimal performance and longevity. They also offer customized services, such as designing metal parts according to specific customer requirements, which further enhances their reputation as reliable partners in the industry.

The applications of CNC plasma cutting are vast and varied, including but not limited to aerospace, automotive, construction, and jewelry making. The precision and speed of this cutting method make it suitable for producing complex geometries and shapes with ease. It can be used to cut through both thin and thick metal sheets, making it a versatile tool in any metalworking project.

A key advantage of CNC plasma cutting is its environmental friendliness. Unlike traditional sawing or milling methods, which emit harmful fumes and waste materials, CNC plasma cutting produces minimal pollution. This makes it an ideal choice for companies seeking to reduce their carbon footprint while still achieving high levels of productivity.

However, despite its many advantages, CNC plasma cutting is not without its challenges. One of the main issues faced by manufacturers is maintaining the accuracy of the cutting process. This requires careful calibration of the machine and constant monitoring of the cutting parameters to ensure precise results. Another challenge is managing the heat generated by the cutting process, which can damage delicate metal components if not handled correctly. To address these challenges, CNC plasma cutting五金厂家 employ sophisticated software and hardware solutions that help them overcome these obstacles.

In conclusion, CNC plasma cutting has revolutionized the metal fabrication industry by providing unparalleled precision and efficiency. The specialized skill and expertise of CNC plasma cutting五金厂家 have made this technology accessible to a wide range of manufacturers across different sectors. As technology continues to advance, we can expect even more sophisticated and effective CNC plasma cutting systems to emerge from these factories, further enhancing our ability to create complex metal components with ease.

Articles related to the knowledge points of this article:

Tianjin Hardware Manufacturers: A Stronghold of Quality and Innovation

Dongguan Spring Hardware Manufacturers

The Journey of a Hardware Manufacturer

Jilin Micro-Hardware Manufacturers

Title: Direct Sales of Kitchen Hardware Manufacturers: A Comprehensive Guide