The Vital Role of Metal Parts and Their Specially Designed Screws in Industrial Assembly

In industrial assembly, metal parts play a crucial role in assembling complex machinery and equipment. However, the success of these assemblies depends on the accuracy and reliability of the screws used to attach the metal parts together. Specially designed screws are essential to ensure proper alignment and tightness of the metal components. These screws have unique features such as thread count, material, and design that enable them to withstand high loads and harsh environments. The use of metal parts and specially designed screws in industrial assembly requires precision and attention to detail to achieve optimal results. Proper maintenance and replacement of these components can also prevent unexpected failures and prolong the lifespan of the assembly. In conclusion, metal parts and specially designed screws are vital components in industrial assembly that contribute to the efficient operation and longevity of machinery and equipment.

In today's fast-paced, technologically-driven world, industrial assembly lines are a ubiquitous sight. The vast majority of modern machinery relies on various metal parts to perform specific functions, and these parts are typically secured using specialized screws. These screws play a pivotal role in ensuring the stability, durability, and efficiency of industrial equipment, making them an indispensable component in any manufacturing process. In this article, we will delve into the significance of五金配件专用螺丝 in industrial assembly and explore their unique characteristics and applications.

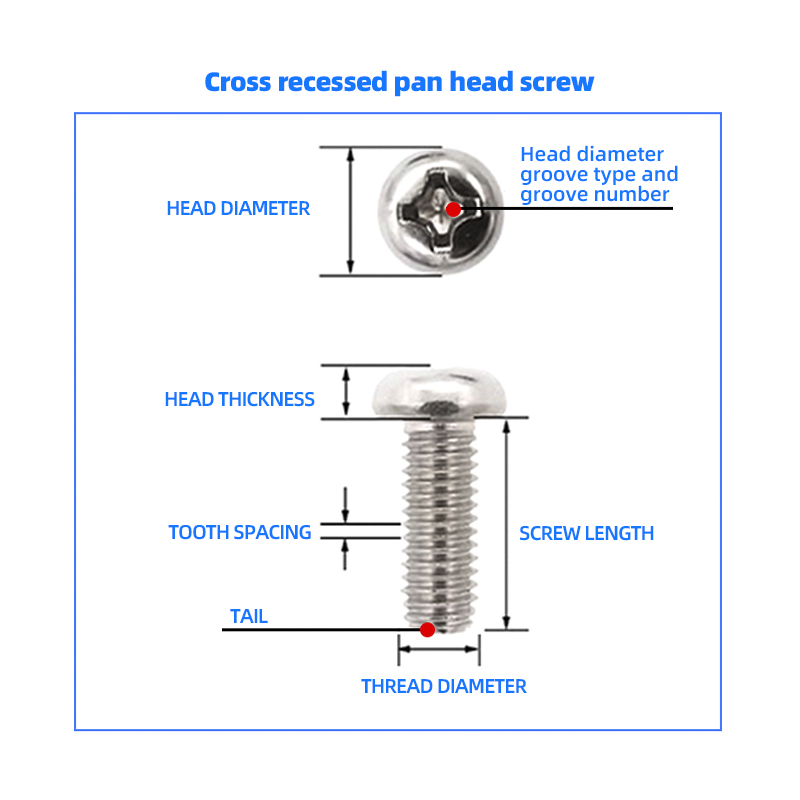

Screws are mechanical fasteners that are used to join two or more objects together. They consist of a screw thread (which provides the necessary tension for holding the objects together) coupled with a cylindrical or helical shape that enables easy rotation around its axis. The head of the screw can be either flat or pointed, depending on the type of material being joined. Metal parts, in particular, require screws that can withstand the stresses and strains generated by their use. This is where五金配件专用螺丝 come into play.

五金配件专用螺丝 are designed specifically for use with metal parts. They are made from high-quality materials such as stainless steel, chrome steel, or titanium alloys, which provide excellent resistance to corrosion and wear. These screws also feature specially shaped tips that allow them to penetrate through thick metals without breaking or damaging the surface. Moreover,五金配件专用螺丝 often have a finer thread pitch than regular screws, which results in a tighter grip and better joint strength. This makes them ideal for use in demanding industrial applications where precision and durability are crucial.

The versatility of五金配件专用螺丝 is another significant advantage they offer. These screws can be used in a variety of ways depending on the application. For example, they can be tightened by hand using a screwdriver or powered tool, or they can be automated using pneumatic or hydraulic systems. Additionally, some五金配件专用螺丝 come with built-in nuts or anchors that make it easier to secure the parts in place. This flexibility allows manufacturers to tailor their assembly processes to meet specific requirements and minimize downtime.

Another critical aspect of五金配件专用螺丝 is their ability to handle different types of metals. Different metals have different properties, such as hardness, density, and ductility, which affect their strength, stiffness, and resistance to wear and tear.五金配件专用螺丝 are designed to work with a wide range of metals, including aluminum, bronze, copper, iron, magnesium, and steel. By selecting the appropriate screw for each metal type, manufacturers can ensure optimal performance and long-lasting reliability. For instance, stainless steel screws are commonly used in applications where corrosion resistance is essential, while titanium screws are ideal for high-strength applications where weight reduction is critical.

In addition to their functional benefits,五金配件专用螺丝 also contribute to environmental sustainability. Traditional screws may contain harmful chemicals that can leach into the environment during use or disposal. However,五金配件专用螺丝 are often produced using environmentally friendly processes that minimize waste and reduce carbon emissions. This makes them an attractive option for companies seeking to reduce their environmental footprint while still meeting production demands.

To conclude,五金配件专用螺丝 play a vital role in ensuring the stability, durability, and efficiency of industrial equipment. These specialized screws are designed to work seamlessly with metal parts and offer numerous advantages over traditional fasteners. From their superior resistance to corrosion and wear to their versatility and ability to handle different metal types,五金配件专用螺丝 are an essential component of modern manufacturing processes. As technology continues to evolve, it is likely that we will see further innovation and development in the field of metal part assemblies and their accompanying screws.

Articles related to the knowledge points of this article:

Title: Curtain Wall Hardware Fittings

Special Discounts on Sichuan Imported五金 Accessories: A One-Stop Solution for All Your Hardware Needs

Title: Understanding the Cost of Nanjing Nuclear Power Plant Hardware Parts

Title: Building Trust and Providing Exceptional Services in Shenzhens Book Hardware Industry