Custom Hardware Manufacturing: A Detailed Guide

This detailed guide to custom hardware manufacturing covers all aspects of the process, from design to production. It includes practical advice and industry best practices that ensure a smooth and successful outcome. Whether you are looking to manufacture a simple device or a complex machinery system, this guide has everything you need to know to make it happen. From materials selection to quality assurance, this comprehensive resource will help you every step of the way. Whether you are a beginner or an experienced manufacturer, this guide can help you improve your skills and increase your productivity. It provides clear explanations and examples that make the complex process of custom hardware manufacturing accessible to everyone.

Hardware components, also known as "五金" in Chinese, are crucial for various applications and products. From simple fasteners to complex machinery parts, these elements play a vital role in the functioning and performance of a product. In this article, we explore the process of custom hardware manufacturing, commonly known as "厂家定制五金" in the Chinese industry.

What is Custom Hardware Manufacturing?

Custom hardware manufacturing refers to the process of designing and producing hardware components specifically for a particular application or product. This process involves the use of advanced manufacturing techniques, such as machining, casting, and molding, to create components that meet specific size, shape, and performance requirements. These components are then assembled into finished products that are tailored to meet the needs of a specific customer or application.

Why is Custom Hardware Manufacturing Important?

Custom hardware manufacturing is important because it allows manufacturers to create hardware components that are tailored to meet the specific needs of their customers. By understanding the unique requirements of each application or product, manufacturers can design components that are optimized for performance, cost-efficiency, and reliability. This ensures that each component not only meets the functional requirements but also contributes to the overall quality and performance of the finished product.

How does Custom Hardware Manufacturing Work?

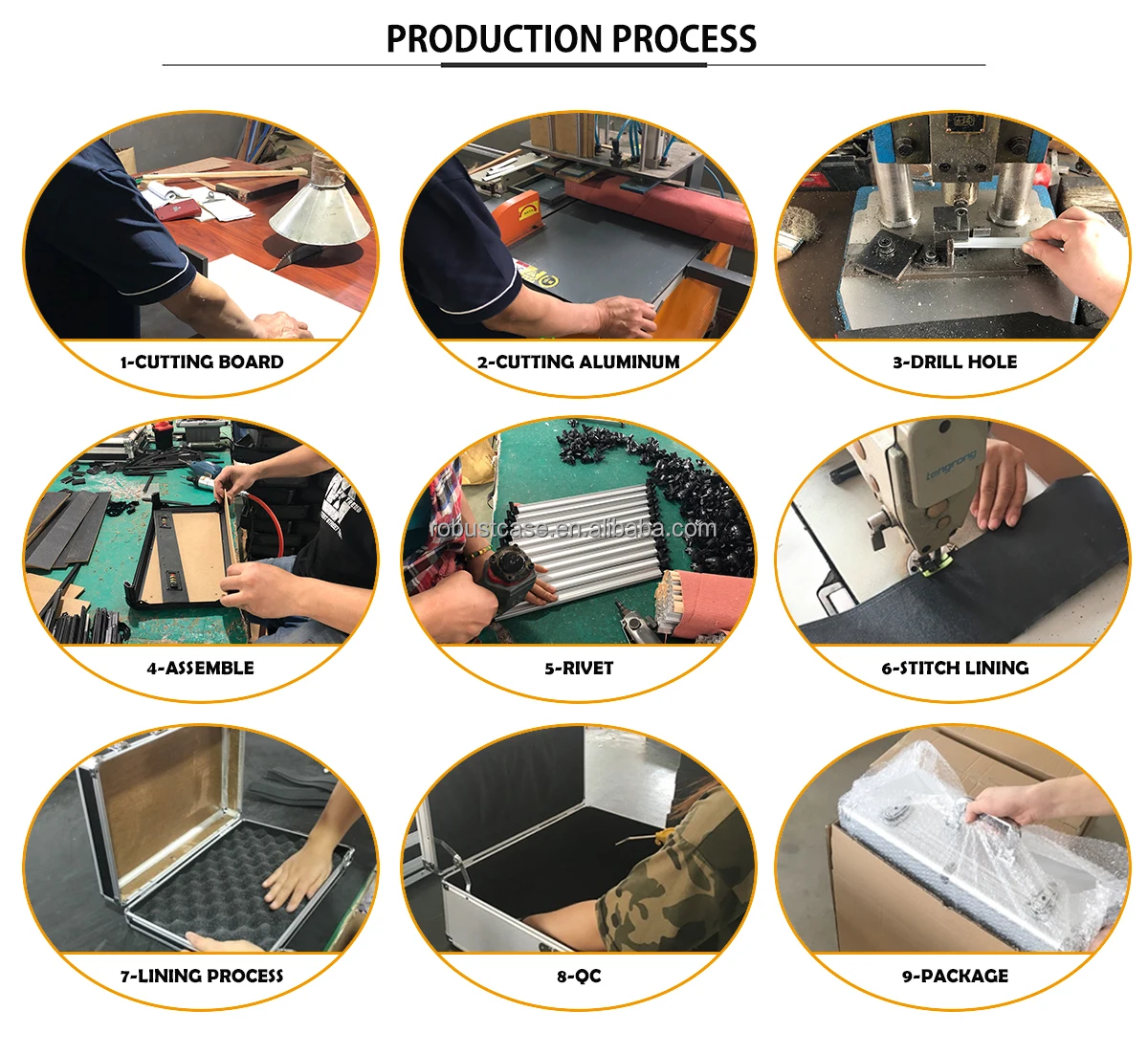

The process of custom hardware manufacturing typically starts with a detailed understanding of the requirements of the application or product. This includes understanding the size, shape, and performance characteristics that the component needs to have. Once these requirements are clear, manufacturers can then proceed with the design phase of the component.

During the design phase, manufacturers use CAD (Computer-Aided Design) software to create virtual models of the component. These models are then used to simulate the performance of the component under various conditions to ensure its reliability and performance. Once the design is finalized, manufacturers can proceed with the manufacturing phase.

In the manufacturing phase, manufacturers use advanced manufacturing techniques, such as machining, casting, and molding, to create the actual component. This process involves precise cutting, drilling, and shaping of the material to achieve the desired shape and size of the component. Additionally, manufacturers also ensure that the component meets all the specified performance standards by conducting rigorous testing and quality control procedures.

Once the component is manufactured and tested, it is then assembled into the finished product. This process involves connecting various components together to create a functional and reliable product that meets the specific needs of the customer.

Conclusion

Custom hardware manufacturing, commonly known as "厂家定制五金" in Chinese, is a crucial process for creating hardware components that meet specific size, shape, and performance requirements. By understanding the unique needs of each application or product, manufacturers can design components that are optimized for performance, cost-efficiency, and reliability. This ensures that each component not only meets the functional requirements but also contributes to the overall quality and performance of the finished product.

Articles related to the knowledge points of this article:

Custom Cabinet Hardware Brands: A Comprehensive Guide

Title: Understanding the Cost of Custom Metal Components in Shanghai Industrial Sector

Nanjing Custom Hardware in Stock

Hebei Hardware Injection Molding Customization

Title: Customizing Hardware Checklist Template for Effective Project Management

Title: Customizing Home Decoration with Durable Hardware Brands