Customizing Unique Metal Hardware Components: A Comprehensive Guide

Customizing unique metal hardware components is an art that requires precision and creativity. The process involves selecting the appropriate materials, designing the shape and size according to the requirement, and manufacturing it using various techniques such as laser cutting, stamping, and welding. To customize metal hardware components, one must have a good understanding of metal properties and design principles. It is also important to choose the right suppliers who can offer high-quality materials and reliable services. With the increasing demand for customized hardware components in industries such as automotive, aerospace, and medical, the market for custom metal fabrication is rapidly growing. By providing personalized solutions, businesses can stand out from their competitors and meet the specific needs of their customers. In conclusion, customizing unique metal hardware components is not only a valuable skill but also an essential aspect of modern manufacturing.

As the demand for innovative and customized metal hardware components continues to grow, more and more manufacturers are turning to bespoke solutions to meet specific customer requirements. Custom-made metal parts not only offer a high degree of personalization but also contribute to cost savings and improved productivity. In this comprehensive guide, we will explore the process of creating custom-made metal hardware components, from design to production, and discuss the benefits of using such products.

1. Designing Custom Metal Hardware Components

The first step in creating custom metal hardware components is designing the product. This involves determining the type of metal used, its shape, size, and other specifications based on the customer's requirements. There are various software programs available that can help designers create 3D models of their designs, making it easier to visualize the final product. Once the design is finalized, it is important to consider factors such as material strength, corrosion resistance, and ease of manufacturing when selecting the appropriate metal type.

2. Sourcing Raw Materials

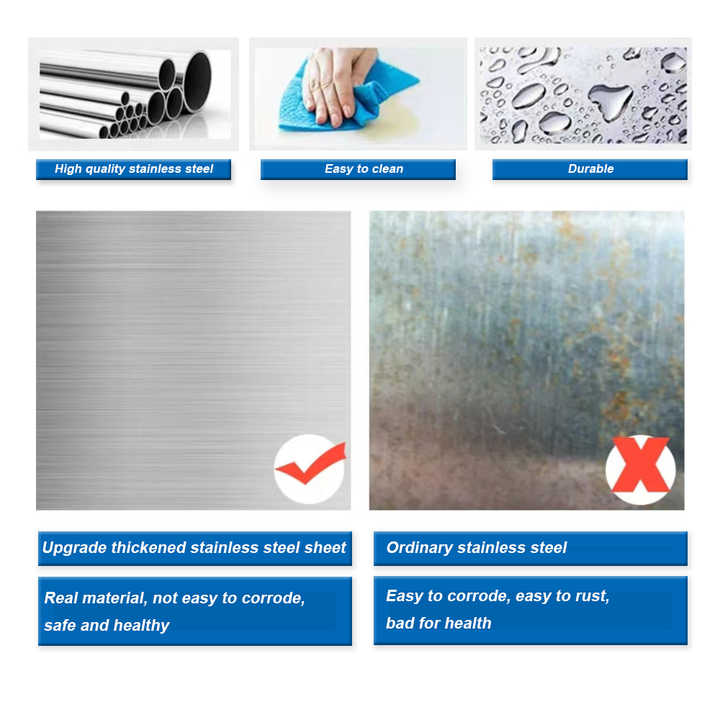

After designing the custom metal hardware component, the next step is sourcing the raw materials needed to produce it. This may involve working directly with suppliers who specialize in the specific metal type required, or searching online marketplaces to find a suitable supplier. It is important to ensure that the raw materials used are of high quality and consistent in terms of strength and durability.

3. Manufacturing Custom Metal Hardware Components

The actual production of custom metal hardware components typically involves several steps, including cutting, drilling, welding, shaping, and finishing. Each of these steps requires specialized equipment and skilled workers who are familiar with the specific techniques required for producing the desired outcome. Some common manufacturing processes used to produce custom metal hardware components include sheet metalworking, stamping, and forming.

4. Quality Control and Inspection

Quality control is an essential part of the manufacturing process for custom metal hardware components. During production, it is important to monitor each stage carefully to ensure that the final product meets the specified requirements. This may involve conducting inspections at different stages of production, such as during cutting, drilling, welding, and finishing. Any defects or issues identified during inspection must be addressed promptly to prevent them from impacting the overall quality of the final product.

5. Packaging and Shipping Custom Metal Hardware Components

Once the custom metal hardware component has been manufactured and inspected to ensure quality, it can be packaged for shipment. The packaging should be designed to protect the product during transportation while still allowing for easy handling and storage on arrival at the customer's location. Common packaging options for custom metal hardware components include wooden crates, plastic bags, and cardboard boxes. Shipping costs can vary depending on factors such as distance, weight, and shipping method, so it is important to work with a logistics provider that offers competitive rates and reliable service.

Benefits of Using Custom Metal Hardware Components:

Custom metal hardware components offer several key benefits over standard off-the-shelf products:

1. Personalization: Custom metal hardware components allow customers to create unique products that reflect their brand identity or individual style preferences. This can help businesses stand out in a crowded market and build strong customer loyalty.

2. Cost savings: By eliminating the need to purchase standard sizes and shapes of metal parts, manufacturers can reduce waste and save money on materials and labor costs associated with producing one-off products. Additionally, by optimizing production processes and minimizing lead times, custom metal hardware components can help businesses improve efficiency and reduce production costs over time.

3. Improved productivity: Custom metal hardware components can help businesses increase productivity by providing access to a wider range of shapes, sizes, and features than what is available from standard suppliers. This can enable companies to create more complex products with greater precision and consistency, improving overall quality and reducing errors during production.

Conclusion:

Creating custom metal hardware components requires careful planning and attention to detail throughout each stage of the manufacturing process. However, the benefits of using such products can be significant for both businesses and consumers alike. By offering personalized solutions that enhance brand recognition, reduce costs, and improve productivity, custom metal hardware components have become an increasingly popular choice among manufacturers seeking to differentiate themselves in today's competitive marketplace

Articles related to the knowledge points of this article:

Custom Metal Fabrication: A Versatile and Efficient Solution for Your Unique Needs

Custom Cabinet Hardware Images: A Guide to Designing Your Perfect Kitchen

Custom Hardware in Qingyuan: Quality and Versatility

Title: Custom Precision Metal Stampings in Meizhou: The Ultimate Guide