Understanding the Cost of Customized Hardware Buckles

Customized hardware buckles refer to those designed according to specific customer requirements, such as shape, size, material, and function. The cost of customized hardware buckles is mainly composed of labor costs, material costs, equipment costs, and other factors. Labor costs refer to the salaries and bonuses paid to employees who design, produce, and test the customized buckles. Material costs include the purchase of raw materials such as metal, plastic, rubber, and other components needed for manufacturing. Equipment costs involve purchasing or renting specialized machinery and tools required for production. Other factors that affect the cost of customized hardware buckles include transportation, packaging, and marketing expenses.To reduce the cost of customized hardware buckles, manufacturers should consider using cost-effective materials, optimizing production processes, and adopting advanced technologies such as 3D printing and automation. They can also collaborate with suppliers to obtain bulk discounts on raw materials and equipment. Additionally, implementing lean production principles and continuous improvement initiatives can help improve efficiency and reduce waste.In conclusion, understanding the cost of customized hardware buckles is essential for manufacturers seeking to optimize their production processes and increase profitability. By identifying areas where costs can be reduced and implementing strategies to reduce them, companies can stay competitive in the market and deliver high-quality products at affordable prices.

In today's highly competitive market, customization has become a common demand in various industries. One area where customization is particularly relevant is in the manufacturing of hardware buckles. These small but essential accessories are used in a wide range of applications, from clothing and accessory items to industrial equipment and safety gear. As such, they require precise measurements and unique designs to satisfy specific customer requirements. This article explores the cost of customized hardware buckles and the factors that affect this price.

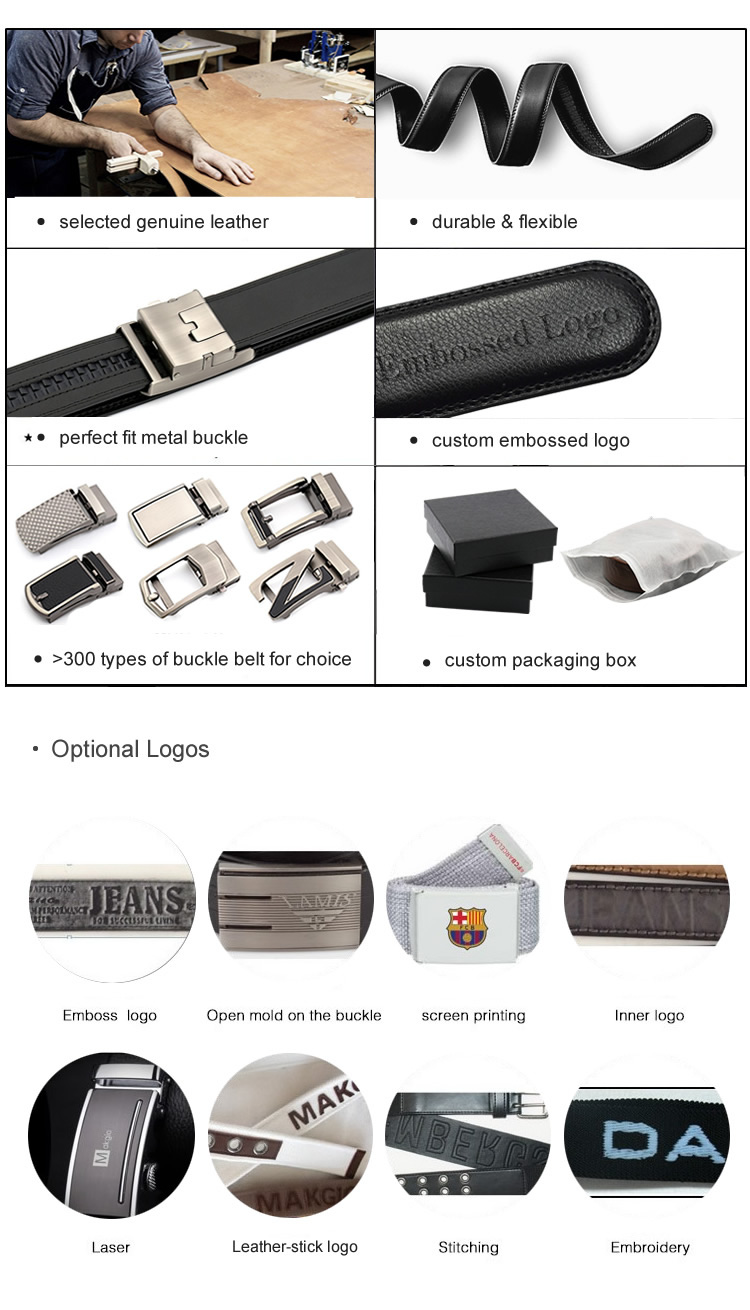

Hardware Buckle Design and Materials

The design of a hardware buckle plays a significant role in determining its cost. The complexity of the design, including the number of holes, shapes, and sizes, can greatly increase or decrease production time and material usage. Additionally, the materials used to manufacture the buckle also impact the cost. Common materials for hardware buckles include stainless steel, brass, aluminum, and plastic. Each material has its advantages and disadvantages, such as durability, corrosion resistance, and weight. Therefore, choosing the right material depends on the intended use and application of the buckle.

Production Process and Factory Environment

The manufacturing process also affects the cost of customized hardware buckles. Factors like assembly line setup, machine efficiency, labor costs, and raw material procurement all contribute to the overall production cost. Moreover, the factory environment plays a crucial role in ensuring quality control and reducing waste. A well-equipped and organized factory with efficient management practices can significantly reduce production costs while maintaining product quality.

Quality Control and Inspection

Quality control is an essential part of the manufacturing process that ensures the final product meets customer expectations. Quality inspection involves checking every stage of production, from raw material procurement to final assembly, to identify any defects or inconsistencies. This process requires specialized equipment and trained personnel, which increases production costs. However, it is crucial to maintain high standards of quality to build brand reputation and customer trust.

Customization Options and Features

Customization options and features can also impact the cost of customized hardware buckles. For example, adding engraved text or logos can make the buckle more personalized and attractive but may increase production time and material usage. Similarly, incorporating additional functions like locking mechanisms or retractable clasps can add complexity to the design but may also increase costs. Therefore, customers should carefully consider their customization requirements when requesting quotes from manufacturers.

International Trade Regulations and Taxes

When importing or exporting customized hardware buckles internationally, customers must comply with trade regulations and pay applicable taxes. These regulations vary by country, and they often include tariffs, quotas, and other restrictions on imported products. Customers should research these regulations before placing orders to avoid unexpected costs or delays in shipping.

Conclusion

Understanding the cost of customized hardware buckles involves considering various factors such as design, materials, production process, quality control, customization options, and international trade regulations. By analyzing each factor carefully, customers can obtain accurate quotations from manufacturers and make informed decisions about their needs and budget. In conclusion, while there are several factors that can influence the cost of customized hardware buckles, careful consideration and planning can help businesses achieve their goals within their budget constraints.

Articles related to the knowledge points of this article:

Customized Hardware Components by Weiyi - A Premier Provider of Quality and Precision

Custom Metal Plate Manufacturers

Title: Crafting Custom Metal Toys: A Unique and Personalized Experience