The Workflow of a Hardware Manufacturer

The workflow of a hardware manufacturer is a crucial aspect of the company's operations. It entails various stages, each of which contributes to the creation of the final product. From design to production, the process involves numerous decisions and actions that ensure the quality and efficiency of the final output. The manufacturer's role is to coordinate these activities and ensure that they are executed effectively and according to the company's vision. By understanding and optimizing the workflow, a hardware manufacturer can significantly improve its productivity and profitability.

In the hardware manufacturing industry, the process of creating high-quality products from raw materials to finished goods is essential. This article introduces the workflow of a hardware manufacturer, focusing on the main steps and considerations that ensure the smooth operation of the factory.

1、Raw Material Procurement

The first step in hardware manufacturing is the procurement of raw materials. These materials are the foundation of the final product and, therefore, must be of high quality and suitable for the intended purpose. Manufacturers source these materials from reliable suppliers and ensure their quality through rigorous testing and inspection processes.

2、Material Preparation

Once the raw materials are procured, they undergo a series of preparation processes before being used in the actual manufacturing process. This includes cutting, grinding, polishing, and other similar operations that transform the materials into the desired shape and size. This step is crucial as it lays the foundation for the final product's quality and performance.

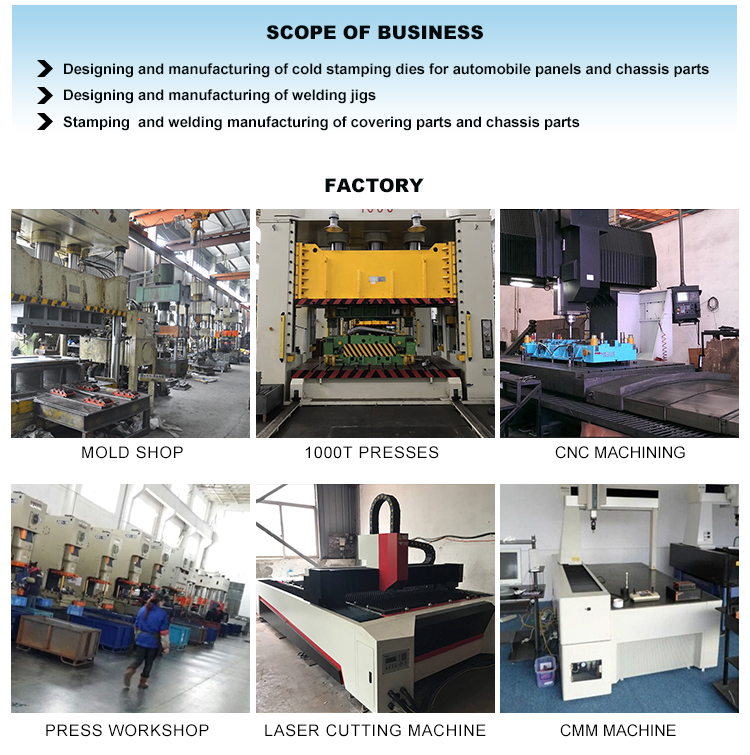

3、Manufacturing Processes

The manufacturing processes themselves vary depending on the type of hardware being produced. Common processes include machining, stamping, molding, casting, and others. These processes involve the use of machines and tools that shape the materials into their final form. It is essential to choose the right manufacturing process for each application to ensure efficiency and product quality.

4、Quality Control

Quality control is a crucial aspect of hardware manufacturing. It ensures that each product meets the specified standards and requirements. Manufacturers use various techniques to control quality, such as inspecting the finished products, conducting periodic audits of the manufacturing process, and using statistical process control (SPC) tools to identify and correct any deviations from the norm.

5、Packaging and Distribution

Once the products have been manufactured and quality controlled, they are packaged for distribution to customers. Packaging involves protecting the product from damage during transportation and providing any necessary documentation or accessories. Manufacturers ensure that their packaging meets all applicable regulations and customer requirements to ensure a smooth and efficient distribution process.

6、Customer Service and Support

After the products have been distributed to customers, manufacturers provide ongoing customer service and support to ensure that their products continue to meet customer needs and expectations. This may involve responding to inquiries or complaints, providing technical support or training, or even offering product updates or upgrades to keep customers satisfied with their purchase.

In conclusion, the workflow of a hardware manufacturer involves multiple steps that ensure the smooth operation of the factory and the creation of high-quality products that meet customer needs and expectations. From raw material procurement to customer service and support, each step is crucial in ensuring the overall success of the hardware manufacturing business.

Articles related to the knowledge points of this article:

Nanjing Direct Sales Hardware Manufacturers’ Stock

Title: Exploring the Latest Innovations in Shenzhens New Hardware Manufacturers

Title: Innovative Furniture Lighting Solutions from Fushun Cabinet Hardware Manufacturers

Title: Ranking of Water Bottle Polishing Hardware Manufacturers in China