Custom-Made Hardware for Unique Applications

Unique applications often require custom-made hardware to ensure optimal performance and compatibility. This hardware is designed specifically for the application, providing a tailored solution that meets its specific needs. By creating hardware that is tailored to the application, it ensures that the hardware and software work together seamlessly to achieve the desired results. This approach can also help to maximize performance and efficiency, as the hardware is designed to work in harmony with the software to achieve optimal performance. Additionally, custom-made hardware can help to reduce cost and improve reliability, as it eliminates the need for unnecessary components and ensures that all components are working together effectively. This approach can also help to protect against system failures, as the hardware is designed to be robust and reliable to ensure that the application can continue to operate without interruption. In conclusion, custom-made hardware for unique applications provides a cost-effective, efficient and reliable solution that ensures optimal performance and compatibility.

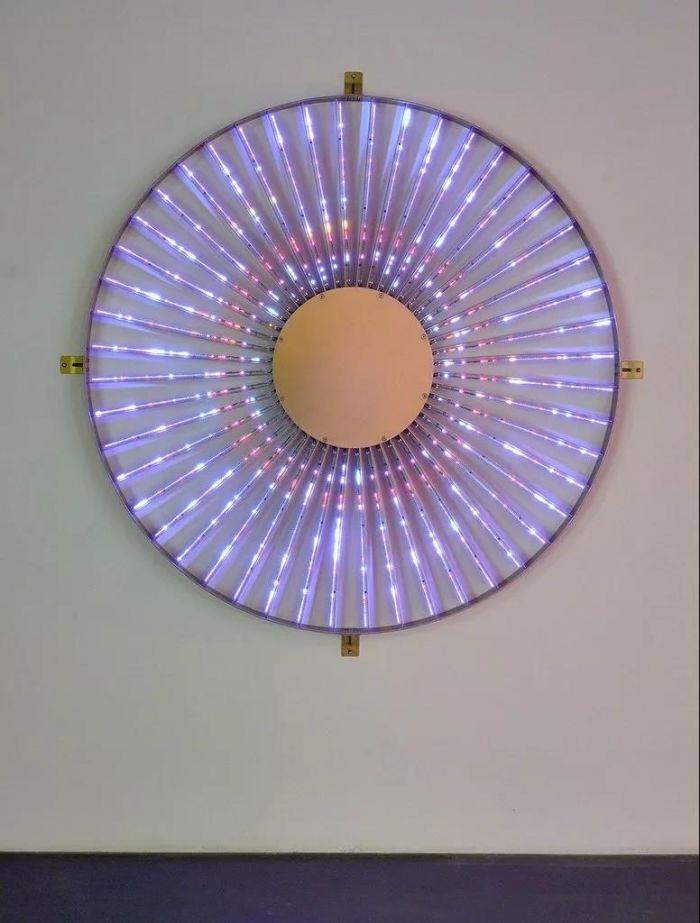

In the world of industrial design and manufacturing, there is a growing demand for hardware components that are as unique and individual as the projects they are a part of. From high-end technology to consumer electronics, the need for specialized, custom-made hardware has become increasingly important. This is where the concept of “异形定制五金” comes into play.

异形定制五金, as the name suggests, refers to hardware components that are designed and manufactured to fit specific, often irregular shapes or requirements. These components are tailor-made to fit into a particular device or product, providing maximum performance and efficiency while meeting the unique challenges of each project.

In the world of technology, where devices are becoming smaller, lighter, and more complex, the role of异形定制五金is becoming increasingly crucial. For example, in the field of robotics, where every inch of space counts and precision is key,异形定制五金components are used to create joints, gears, and other critical components that allow robots to move swiftly and accurately. Similarly, in the aerospace industry, where weight and performance are of the essence,异形定制五金parts are used to manufacture lightweight yet strong structures that can withstand the rigors of space travel.

Consumer electronics is another area where异形定制五金components are making a significant impact. From smartphones to laptops, the use of异形定制五金parts has become common practice. These components are designed to fit into specific devices, providing maximum performance and efficiency while meeting the unique challenges of each project. For example, in the case of smartphones,异形定制五金parts are used to create custom-made cases and covers that protect the device from damage while adding style and functionality.

Another advantage of异形定制五金is its adaptability to different manufacturing techniques and materials. By using advanced technologies like additive manufacturing (AM) or subtractive manufacturing (SM), manufacturers can create complex shapes and designs that are not possible using traditional manufacturing methods. This allows for greater creativity and innovation in product design, resulting in more unique and functional hardware components.

In conclusion,异形定制五金is changing the landscape of industrial design and manufacturing. By providing tailor-made solutions to unique problems, these components are allowing manufacturers to create products that are more efficient, more functional, and more beautiful than ever before. With the continued growth of technology and consumer electronics, the role of异形定制五金will become even more important in the years to come.

Articles related to the knowledge points of this article:

Customizing Baggage Hardware Components: A Detailed Guide

Title: Chongqing Hardware Customization Manufacturers