Customizing Electronic Hardware and Screws for Precision Manufacturing

Title: Customizing Electronic Hardware and Screws for Precision ManufacturingThis study explores the importance of tailor-making electronic hardware and screws for precision manufacturing processes. The authors highlight the need to design these components with high precision, accuracy, and reliability, especially in industries like aerospace, automotive, and medical devices where precision is paramount. They introduce various techniques such as computer-aided design (CAD) software, finite element analysis (FEA), and 3D printing technologies that can aid in creating customized parts that meet stringent standards. The study also discusses how to select suitable materials for these custom-designed parts, considering factors like strength, flexibility, and compatibility with existing systems. Furthermore, it emphasizes the importance of quality control measures during the manufacturing process, including testing, inspection, and certification. In summary, this research highlights the critical role of customizing electronic hardware and screws for precision manufacturing to achieve optimal performance and longevity in demanding applications.

Introduction

In the modern electronics industry, precision is paramount. From the smallest microchips to intricate circuit boards, every part must be crafted with the utmost care and accuracy. This is where the art of customization comes into play. By utilizing advanced technology and a deep understanding of the latest manufacturing techniques, we can produce electronic hardware and screws that meet the stringent standards required by leading companies in the field. In this article, we delve into the world of custom electronic hardware and screws, highlighting how our expertise allows us to provide solutions tailored specifically to each client's needs.

Customization in Electronic Hardware Production

At our factory, we are experts at creating customized electronic hardware products that cater to the unique requirements of our clients. Our skilled engineers work closely with our clients to develop designs that are not only functional but also visually striking. Whether it's a sleek new smartphone case or a high-quality power bank, we take pride in producing products that are not only durable but also aesthetically pleasing.

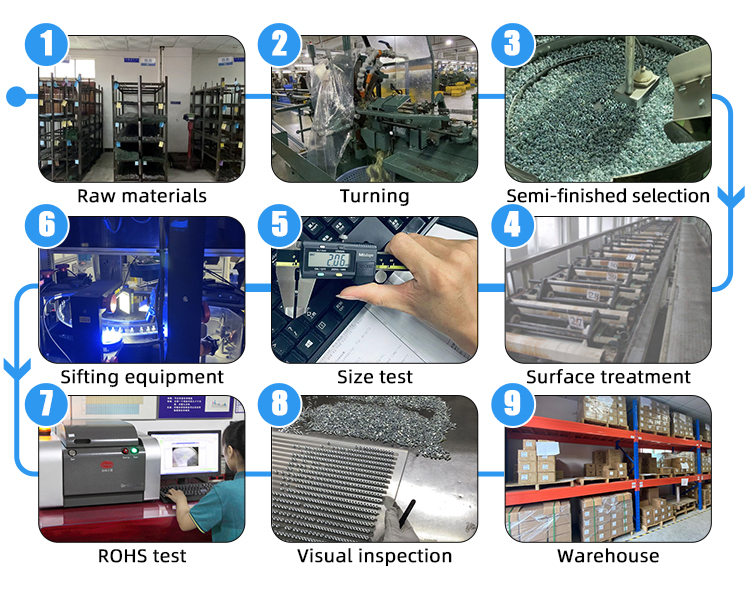

Our process starts with a thorough analysis of the client's requirements. We understand that every product must be designed to meet specific standards, including weight, durability, and functionality. Based on this information, our engineers create sketches and blueprints that are then translated into precise 3D models. These models are then used to guide the production process, ensuring that every component is precisely cut, drilled, and assembled according to the highest standards of precision and quality.

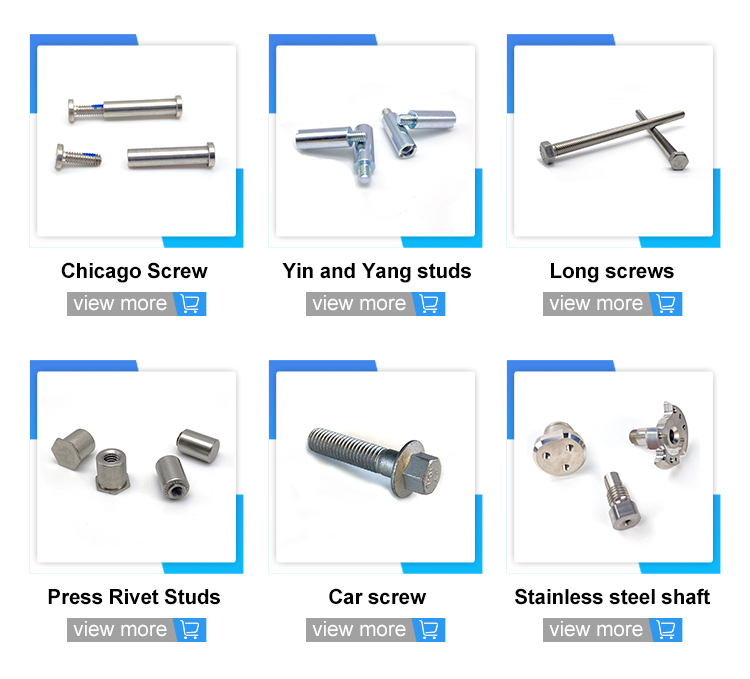

Customization in Screw Manufacturing

When it comes to custom screw production, our expertise extends beyond design. Our team of experienced technicians is equipped with the latest tools and equipment to manufacture screws that are not only strong and durable but also conform to the strict standards set by various industries, such as automotive, electrical, and medical.

Our commitment to quality extends to the materials we use, as well as the processes we follow. We source high-grade steels and alloys that are both rust-resistant and corrosion-resistant, ensuring that our screws last long even under harsh conditions. Additionally, we use state-of-the-art cutting and grinding technologies to ensure that each screw is cut to the exact specifications required by our clients. This precision allows us to produce screws that are virtually impossible to distinguish from those made by other manufacturers, providing our clients with an unmatched level of quality and reliability.

Benefits of Customized Hardware and Screws

At our factory, we understand the importance of customized hardware and screws in meeting the needs of our clients. By providing customized products, we offer a range of benefits, including:

1、Customization: Our customization services allow us to create products that meet the exact specifications of our clients. Whether it's designing a new phone case with a unique shape or creating a high-quality power bank with specific features, we have the skills and expertise to deliver what you need.

2、Cost-Effectiveness: Customization often leads to lower costs than mass production, as there are fewer components and waste materials generated. By working directly with our clients, we can optimize the production process to achieve greater efficiency and reduce overall expenses.

3、Durability: Our customized hardware and screws are built to withstand the test of time. They are designed to withstand heavy loads, extreme temperatures, and harsh environments, ensuring that our clients' products remain functional for years to come.

4、Customization: At our factory, we specialize in creating customized hardware and screws that match the unique style and appearance of our clients' products. Whether it's a sleek new smartphone case or a high-quality power bank, we can create a product that stands out from the crowd and captures the attention of potential customers.

5、Customer Satisfaction: By offering customized hardware and screws, we ensure that our clients receive products that meet their exact specifications and requirements. This results in higher customer satisfaction levels, as customers feel confident in the quality and performance of their products.

Conclusion

At our factory, we specialize in creating customized electronic hardware and screws that meet the needs of our clients in ways that no other manufacturer can. With our extensive experience in design, production, and customization, we are confident in our ability to provide our clients with high-quality products that exceed expectations. Contact us today to learn more about how we can help you create your customized hardware and screws today!

Articles related to the knowledge points of this article:

Title: Custom Metal模具外壳 Manufacturing: A Comprehensive Guide

Custom Hardware Knowledge Explanation

Title: A Comprehensive Comparison of Whole House Customized Hardware Solutions