Custom Manufacturing of Electrical Hardware

Custom Manufacturing of Electrical Hardware Custom manufacturing of electrical hardware is a specialized service that involves the production of customized electrical components and assemblies according to the specific needs of customers. These components are designed to meet the unique requirements of various electrical systems and applications, such as power distribution, lighting, and industrial machinery. Custom manufacturing allows for the creation of electrical hardware that is tailored to the individual needs of each customer, providing a high level of customization and flexibility. This approach allows for the production of high-quality, cost-effective electrical hardware solutions that meet the specific demands of each application. Custom manufacturing also ensures that all components are designed and produced under strict quality control measures, ensuring reliable and long-lasting performance. In conclusion, custom manufacturing of electrical hardware is a beneficial service that allows for the production of tailored solutions that meet the individual needs of each customer, providing high levels of customization and flexibility.

In modern industrial production, the demand for customized electrical hardware components is on the rise. As technology advances, so do the complexity and precision requirements of these components. Enterprises worldwide are looking for reliable and high-quality custom manufacturers to meet their specific needs. This article introduces an electrical hardware processing factory that excels in customized manufacturing, offering a range of services to meet the diverse demands of its customers.

An electrical hardware processing factory specializes in the manufacture of customized electrical components. These components are designed to meet the specific requirements of various industries, including automotive, aerospace, medical, and more. The factory boasts a team of skilled engineers and technicians who have extensive experience in the field, offering customized solutions to meet the challenges of each industry.

In addition to standard electrical components, the factory also produces non-standard parts tailored to customer specifications. This involves designing and manufacturing components that are unique to each application, offering maximum flexibility and precision in production. The factory's capabilities include CNC machining, wire cutting, bending, and other value-added processes to ensure that each component meets the highest quality standards.

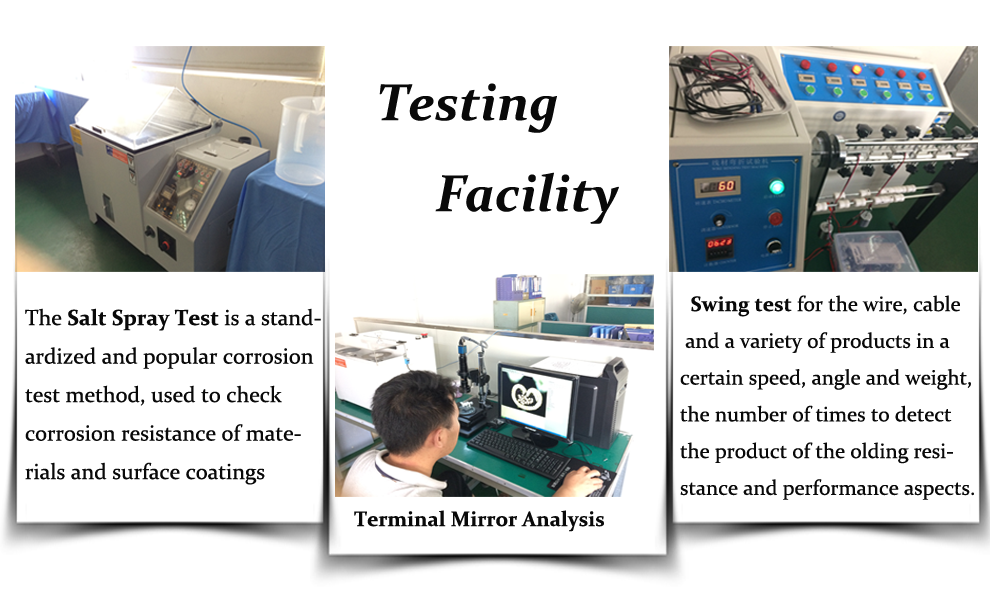

Moreover, the electrical hardware processing factory partners with leading material suppliers to ensure that it uses the best quality materials available. This ensures durability and longevity of the products, reducing maintenance costs and downtime for its customers. The factory also offers testing and inspection services to ensure that each component meets the specified standards before it leaves the factory.

In conclusion, a reliable electrical hardware processing factory offers customized manufacturing services to meet the diverse demands of its customers. By specializing in the manufacture of customized electrical components, it ensures that each component meets the highest quality standards, offering maximum flexibility and precision in production. Partnering with leading material suppliers and offering testing and inspection services are added advantages that contribute to the overall quality of the products. Whether you are looking for standard electrical components or non-standard parts tailored to your specifications, an electrical hardware processing factory can provide you with a solution that meets your needs.

Articles related to the knowledge points of this article:

Custom Hardware Fabrication in Linhai: A Comprehensive Guide

Title: Customized Weifang Hardware Painting Equipment: A Comprehensive Guide

Zhoushan Undertakes Customized Hardware Production

Title: Customized Heavy Metal Hardware in Neihuang: A Solution for All Your Needs