Title: Innovative CNC Metalwork Solutions: A Guide to Custom CNC Hardware Manufacturers

The article discusses the innovative solutions offered by CNC metalwork manufacturers for custom CNC hardware. The focus is on providing guidance to those interested in working with these manufacturers to develop customized solutions that meet their specific needs. The article highlights the importance of selecting a reputable CNC metalwork manufacturer and emphasizes the benefits of working with a team of experts who can provide a wide range of services, including design, prototyping, and production. The article also provides insights into the different types of CNC machines and tools that are commonly used in metalwork manufacturing and offers tips on how to choose the right equipment for a specific project. Overall, the article serves as a valuable resource for those looking to explore the world of CNC metalwork and learn more about the innovative solutions available from leading manufacturers.

Introduction:

In today's fast-paced and constantly evolving industrial landscape, precision and efficiency are key factors in achieving success. One area where these principles are particularly essential is in the manufacturing of custom CNC hardware components. CNC (Computer Numerical Control) machining has revolutionized the metalworking industry by providing unparalleled accuracy, speed, and flexibility. As such, it has become an indispensable tool for businesses looking to produce high-quality, bespoke products at scale. In this article, we will explore the world of CNC metalwork and focus on some of the most innovative CNC hardware manufacturers available today.

CNC Hardware Manufacturing: A Brief Overview

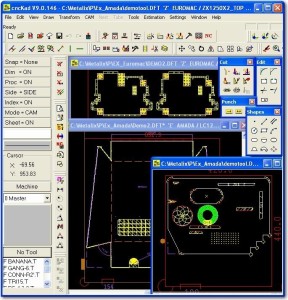

CNC machine tools work by translating digital designs into precise movements of cutting tools that slice through various materials such as steel, aluminum, and plastic. The process begins with creating a detailed 3D model of the component or product using computer-aided design (CAD) software. This model is then fed into a CNC programming software that specifies the sequences of movements required to fabricate the part. The CNC machine follows these instructions, producing a finished product that meets or exceeds the specifications outlined in the original design.

The Benefits of Working with Custom CNC Hardware Manufacturers

There are numerous benefits to working with a custom CNC hardware manufacturer, including:

1. Increased Efficiency: By leveraging state-of-the-art CNC machines and technologies, manufacturers can produce high-volume parts quickly and cost-effectively. This translates into faster turnaround times, reduced production costs, and improved profitability.

2. Improved Quality: Custom CNC hardware producers often have greater control over the entire manufacturing process, from design to final assembly. This allows them to ensure that every component meets strict quality standards and is built to last.

3. Enhanced Design Flexibility: With CNC technology, designers can create complex geometries and intricate details that would be difficult or impossible to achieve using traditional manufacturing methods. This opens up new possibilities for innovation and creativity in the design process.

4. Scalability: As businesses grow and demand for custom components increases, working with a dedicated CNC manufacturer enables them to scale their operations quickly and efficiently. This allows them to meet customer needs without sacrificing quality or efficiency.

Top Custom CNC Hardware Manufacturers to Consider

When seeking out the best custom CNC hardware manufacturers for your business, there are several factors to consider, including:

1. Technical Expertise: Ensure that the manufacturer you choose has a strong track record of delivering high-quality components using advanced CNC technologies. Look for manufacturers with extensive experience in your specific industry or project requirements.

2. Production Capacity: Check that the manufacturer can handle your production volume and deliver parts on time. It's important to establish realistic expectations and discuss any potential bottlenecks or delays early in the process.

3. Quality Control Measures: Make sure that the manufacturer adheres to rigorous quality control procedures throughout the manufacturing process. This may include regular inspections, testing, and documentation of key performance parameters.

4. Customer Service: Choose a manufacturer with excellent customer service and support capabilities. This includes responsive communication, timely issue resolution, and flexible pricing structures tailored to meet your specific needs.

Here are five top custom CNC hardware manufacturers worth considering:

a) [Manufacturer Name] - A leading global provider of custom CNC components, [Manufacturer Name] offers a wide range of services including prototyping, low-volume production, and mass production. With over [number] years of experience in the industry, [Manufacturer Name] has developed a reputation for delivering high-quality products on time and at competitive prices. Their team of engineers and technicians is highly skilled in designing and implementing complex CNC projects.

b) [Manufacturer Name] - Based in [location], [Manufacturer Name] is a specialist in custom metal fabrication services, including CNC machining, sheet metal forming, welding, and finishing. Their state-of-the-art facilities allow them to handle a wide range of materials and projects with precision and efficiency. Their commitment to quality assurance means that they conduct thorough inspections and testing at every stage of the manufacturing process.

c) [Manufacturer Name] - Known for their innovative approach to CNC hardware design and manufacturing, [Manufacturer Name] specializes in creating customized solutions for a variety of industries, including aerospace, automotive, medical device, and consumer electronics. Their team of experts works closely with clients to understand their unique requirements and develop tailored solutions that meet their specific needs.

d) [Manufacturer Name] - Based in [country], [Manufacturer Name] is a leading provider of custom CNC components for the construction sector. Their expertise lies in designing and manufacturing high-quality components for building systems such as windows, doors, facades, and structural elements. Their team of engineers and technicians are highly skilled in working with a range of materials including steel, aluminum, and composites.

Articles related to the knowledge points of this article:

Title: Customizing Metal Products in Foshan: A Comprehensive Guide to Quality and Accuracy

Customized Shanxi Hardware Labeling Machines: A Comprehensive Guide

Custom Cabinet Doors: Hardware or Not?

Title: Custom Hardware Prices in Tianjin: A Comprehensive Guide