Customized Metal Fabrication Equipment for Unique Light Shapes

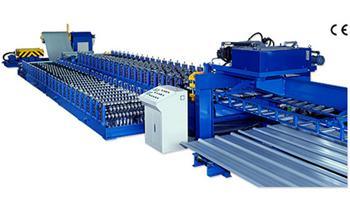

Unique light shapes are made possible by customized metal fabrication equipment. This equipment allows for precision cutting, bending, and welding of metal pieces to create unique designs and shapes that can be used in a variety of applications, such as architectural lighting, interior design, and art installations. By using high-quality materials and advanced manufacturing techniques, these equipment ensure that each light shape is created with precision and accuracy. Customized metal fabrication equipment also allows for mass production of identical light shapes, providing a cost-effective solution for projects that require large quantities of the same design.

In the world of interior design, lighting fixtures have become integral to creating the desired ambiance and atmosphere. One such fixture that has become popular due to its versatility and aesthetics is the customized metal fabrication equipment for unique light shapes. This equipment allows designers and manufacturers to create lights that not only illuminate but also add a touch of uniqueness and creativity to any given space.

The process of creating customized metal fabrication equipment for unique light shapes begins with the design phase. This is where the client and manufacturer collaborate to determine the specific shape, size, and design of the light fixture. The manufacturer will use computer-aided design software to create a digital model of the light fixture, which can then be used to generate a physical prototype.

Once the design is approved, the manufacturing process can commence. This involves cutting, bending, and welding metal pieces together to form the desired shape of the light fixture. The use of high-quality metal materials ensures that the finished product is both durable and aesthetically pleasing. Additionally, this equipment often features advanced welding techniques that ensure seamless joints and strong structural integrity.

Once the metal fabrication equipment is ready, it can be used to create unique light shapes. These shapes can range from simple geometric forms to complex and organic shapes that resemble natural objects or abstract art. The possibilities are endless, limited only by the imagination of the designer.

In conclusion, customized metal fabrication equipment for unique light shapes has become a valuable tool for interior designers and manufacturers. It allows them to create lights that not only serve a practical purpose but also add a touch of uniqueness and creativity to any given space. Whether it is a residential home or a commercial establishment, customized metal fabrication equipment for unique light shapes can transform any interior into a beautiful and inviting environment.

Articles related to the knowledge points of this article:

Title: Innovative Solutions for Customized Hardware in Guiyang - Enhancing Quality and Performance

Title: Comparing Custom Metal Parts: Which Manufacturer is Best?

Custom Hardware Hinges Manufacturers

Title: How to Compare Customized Metal Components: A Comprehensive Guide

Guangdong Mango Hardware Customization: Quality and Service for Your Project