Title: Innovative Automation in Hardware Assembly for Powder Coating Equipment

Powder coating equipment has traditionally been manual, with workers performing assembly tasks in a labor-intensive manner. However, innovative automation has emerged to improve the efficiency and quality of this process. Automated robots can handle complex and repetitive assembly tasks, reducing errors and improving production speed. Additionally, automated inspection systems can quickly detect defects and inconsistencies, ensuring that only high-quality products are produced. This not only improves the overall performance of powder coating equipment but also reduces costs associated with manual labor and downtime. As technology continues to advance, it is expected that more innovations in automated hardware assembly for powder coating equipment will emerge, further enhancing productivity and quality control.

In today's world, automation has become an indispensable aspect of industrial manufacturing processes, particularly in the realm of hardware assembly. One area where this trend has been particularly pronounced is in the field of powder coating equipment, which is widely used in a variety of applications from automotive to aerospace. This article focuses on the use of innovative automation techniques in assembling hardware components for these machines.

Powder coating is a surface coating process that involves the dry-powdering of abrasives onto a surface to be coated. The resulting finish is often used to protect the underlying metal or to enhance its appearance. The efficiency and accuracy of these systems are critical to their success, which is why so much attention is paid to the design and manufacture of the hardware components that make them up.

One key area where automation can improve efficiency and accuracy is in the assembling of these components. In traditional manual assembly methods, human error can be prone, leading to variations in component quality and quantity. Additionally, manual labor can be physically demanding and time-consuming, making it difficult to maintain consistent quality standards.

Automation offers a number of benefits over traditional manual methods. For one, automated machinery can perform tasks with greater speed and precision than humans can. They also do not require rest or breaks, making them ideal for continuous production runs. Moreover, they can be programmed to perform specific tasks based on pre-set parameters, further increasing efficiency and accuracy.

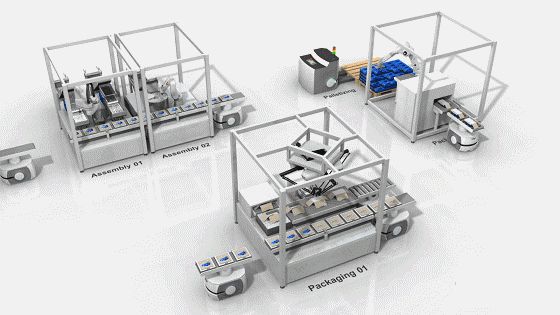

Several types of automation technologies have been developed specifically for use in the powder coating industry. These include robot-based systems, which use mechanical arms and other mechanisms to perform tasks such as assembling components, as well as advanced vision systems that use sensors and cameras to detect and align components accurately. Other technologies, such as computer-controlled machining centers and laser welding machines, can also be used to automate various stages of the hardware assembly process.

However, implementing these technologies requires careful planning and design. It is essential to choose the right type of automation technology for each stage of the process, taking into account factors such as component size, complexity, and the required level of precision. Additionally, the automation system must be able to integrate seamlessly with existing production processes and infrastructure.

One example of successful application of automation in powder coating equipment assembly is a project undertaken by a major manufacturer of such equipment. The company developed an automated assembly line that uses robotic arms to handle various steps in the hardware assembly process. The system is designed to work in conjunction with a computer-controlled machining center that prepares the components for assembly.

The robotic arm features a series of precise tools that can adjust to different component sizes and shapes. It is capable of performing tasks such as threading screws, inserting bolts, and attaching electrical wires with high speed and accuracy. The computer-controlled machining center is responsible for creating the necessary holes and cuts in the components before they are sent to the robotic arm for assembly. This allows for a highly efficient and accurate production process, with minimal room for human error.

Another advantage of this approach is that it allows for continuous production runs without needing frequent maintenance or downtime for cleaning or retooling. This translates into significant cost savings for the manufacturer, as well as increased customer satisfaction due to faster delivery times and higher quality products.

In conclusion, the use of automation technology has revolutionized the hardware assembly process for powder coating equipment. By reducing human error and increasing efficiency and accuracy, these systems have helped manufacturers produce higher quality products at a lower cost. As automation technologies continue to advance, we can expect even greater improvements in the efficiency and effectiveness of hardware assembly in the powder coating industry and beyond.

Articles related to the knowledge points of this article:

Title: The Characteristics of Informatized Metal Parts in Qingdao

Title: Promotion of Metal Hardware Components and Materials in Hongkou District

Manufacturing Excellence: The Art of Machine Tool Hardware Processing in a CNC Machine Shop

Title: Affordable Hardware Accessories in the Reliable City of Nantong