Title: The Cost of Customized Metal Parts and Why it Matters

The cost of customized metal parts can vary greatly depending on the complexity of the design, material choice, and production process. However, it is important to consider these factors when making decisions about ordering custom metal parts. One of the biggest factors affecting the cost is material choice. Different metals have different costs, and some may even be more expensive than others. Additionally, production processes can also impact the cost of custom metal parts. For example, if a part requires specialized tools or equipment, this will increase the cost. Another important consideration is the design of the part. Complex designs can be more difficult and time-consuming to produce, which can increase the cost. It is important to work with a reliable manufacturer who can provide accurate quotes based on your specific requirements. This will allow you to make informed decisions and avoid unexpected costs down the road. In conclusion, while the cost of customized metal parts can be high, it is essential to consider all relevant factors before making a decision. By working with a reputable manufacturer and taking into account material choice, production process, and design complexity, you can ensure that you get the best value for your money.

In the world of manufacturing, customized metal parts are a critical component in many industries. From automotive to aerospace, these parts play a significant role in ensuring the functionality, safety, and efficiency of the products they accompany. However, one common issue that often arises during the customization process is the cost. Many customers are surprised to find out that adding customizations to their metal parts can lead to an increase in overall costs. In this article, we will explore the reasons behind this trend and discuss how it affects businesses and consumers alike.

The concept of "customization" when it comes to metal parts is not new. For centuries, blacksmiths and other metalworkers have crafted unique products tailored to the needs of individual customers. However, with the rise of modern manufacturing techniques and technology, mass production has become the norm. This has led to a decrease in the number of skilled craftsmen and an overreliance on standardized designs. As a result, when customers request customized metal parts, they may face unexpected costs due to the added labor and complexity involved in producing these products.

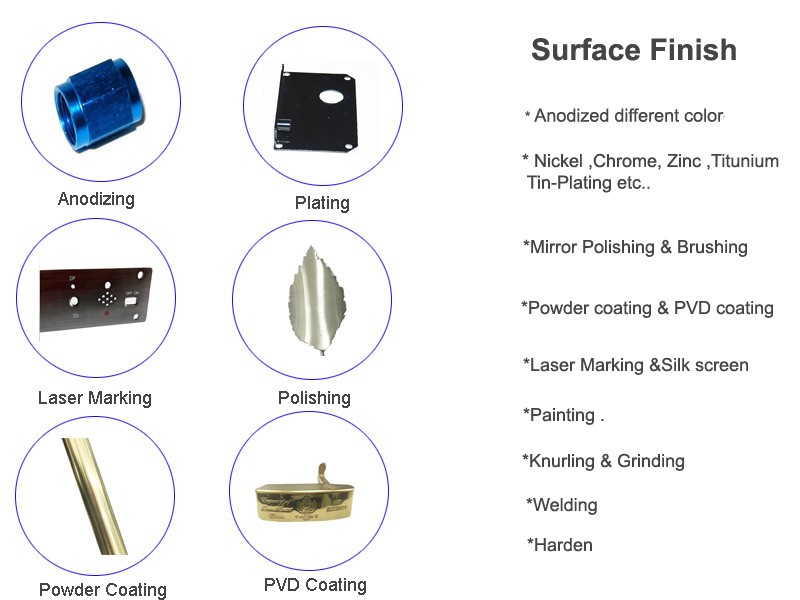

One factor that contributes to the increased cost of customized metal parts is the need for specialized equipment and tools. When producing standard parts, manufacturers can rely on automated processes and pre-engineered machinery to speed up production and reduce costs. However, when working with custom orders, they must invest in additional equipment that may not be necessary for standard production. These investments can include high-tech scanning and measurement devices, specialized fabrication machines, and even trained technicians to handle the unique challenges of customization work.

Another factor that drives up the cost of customized metal parts is the complexity of the design itself. A simple modification or addition may seem like a minor change, but when applied to a larger system or product, it can have a significant impact on its performance and functionality. For example, adding a new feature to an existing part may require modifying the part's geometry or material properties, which can increase production time and costs. Additionally, if the design change involves creating a completely new part from scratch, manufacturers may need to invest in research and development efforts to ensure that the new part meets customer expectations and quality standards.

Despite these factors, there are still advantages to customization in terms of product quality and customer satisfaction. Customized metal parts can help businesses stand out in a crowded market by offering unique features and solutions that meet specific customer needs. They can also provide a better fit for complex systems where standard parts may not perform as expected. Furthermore, customization allows companies to build stronger relationships with their customers by demonstrating a commitment to meeting their specific requirements.

To manage the cost of customized metal parts, it is essential for manufacturers to understand their customers' needs and preferences clearly. By communicating effectively with customers throughout the customization process, businesses can avoid costly surprises down the line and deliver high-quality products that meet their expectations. Customers can also benefit from shopping around for quotes from different suppliers to ensure that they are getting the best value for their money.

In conclusion, while the cost of customized metal parts may seem like an obstacle for businesses looking to add value to their products, it is a reality that must be addressed head-on. By understanding the factors that contribute to this trend and implementing strategies to manage costs effectively, both manufacturers and customers can thrive in a competitive marketplace where innovation and personalization are highly valued. So next time you consider ordering custom metal parts, remember that it may just be worth it in the end!

Articles related to the knowledge points of this article:

Title: Understanding the Cost of Custom Metal Components in Shanghai Industrial Sector

Custom Hardware in Suzhou: Prices and Considerations

Taizhou Custom Hardware for Doors and Windows

Customized Hardware Vocabulary

Title: Is Making Customized Metal Hardware a Profitable Business?