Title: Custom Precision Metal Stamping in Foshan: A Comprehensive Guide

Foshan is a renowned city for its custom precision metal stamping. This article aims to provide you with a comprehensive guide on the process of custom precision metal stamping in Foshan. The first step is to design your product, which can be done through CAD software. Next, you need to choose the right material and supplier for your project. Once you have selected your materials and supplier, you can start the production process. The production process includes designing, tooling, and manufacturing. After the production is complete, the final product needs to be inspected to ensure quality standards are met. Foshan has many experienced professionals in this field who can help you with every step of the process, from initial design to final inspection. With their expertise and advanced technology, they can create high-quality products that meet your specific requirements. In conclusion, if you are looking for custom precision metal stamping services in Foshan, then you should consider working with one of the experienced professionals in this field. They can help you achieve your goals and create products that meet your exact specifications.

Abstract: This comprehensive guide explores the world of custom precision metal stamping in Foshan, China. With a focus on the city's rich history in manufacturing, the article covers key aspects such as industry trends, production processes, materials and design considerations, as well as the benefits and challenges of working with a Chinese metal stamping manufacturer. By understanding these factors, businesses can make informed decisions when choosing a partner for their custom metal stamping needs.

Introduction

Custom precision metal stamping, or metal stamping, is a process of shaping raw metal into intricate designs and structures using specialized tools and machines. This versatile manufacturing technique has been widely adopted across industries due to its ability to produce large volumes of high-quality parts at a relatively low cost. Foshan, located in southern China, has emerged as a leading center for metal stamping in recent years, attracting both domestic and international customers looking to outsource their custom metal stamping needs. In this article, we will explore the key aspects of custom precision metal stamping in Foshan and provide valuable insights for businesses looking to collaborate with Chinese metal stamping manufacturers.

Industry Trends and Developments

Foshan's reputation as a global hub for metal stamping can be attributed to its strong manufacturing base, skilled labor force, and favorable government policies. Over the years, the city has witnessed significant growth in various industries such as automotive, electronics, healthcare, and more, which have driven demand for custom metal stamping services. Furthermore, advancements in technologies such as automation, robotics, and 3D printing are transforming the metal stamping industry by increasing efficiency and improving product quality. As a result, Foshan's metal stamping manufacturers need to stay up-to-date with these developments to remain competitive.

Production Processes

The process of custom precision metal stamping typically involves several steps, starting from raw material selection to final product assembly. Here is an overview of each stage:

1. Raw Material Selection: Depending on the specific requirements of the customer, the raw material (usually metal sheets or bars) may be selected based on factors such as thickness, grade, and surface finish. Some common raw materials used in metal stamping include aluminum, steel, titanium, and plastic.

2. Design Development: Once the raw material is selected, the next step is to develop the design for the part or product that will be produced. This may involve creating prototypes using computer-aided design (CAD) software or working directly with engineers to refine the design based on feedback from previous iterations.

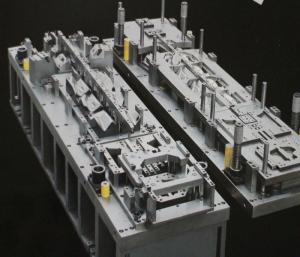

3. Tooling Development: To create accurate patterns for cutting and bending the raw material into desired shapes, specialized tooling must be designed and produced. This may involve creating molds, die sets, and other mechanical parts that are used in conjunction with CNC (computer numerical control) machines to carry out the actual stamping process.

4. Production Setup: Before starting production, the factory must ensure that all necessary equipment and facilities are in place, including machinery, workstations, and logistics systems. The production team must also receive training on how to operate the machines effectively and safely.

5. Quality Control: Throughout the production process, it is essential to maintain strict quality standards to ensure that the final product meets customer expectations. This may involve performing regular inspections on raw material, tooling, and finished products using advanced testing techniques such as X-ray analysis or visual inspection. Any defects or issues found during production must be addressed promptly to avoid delays and minimize waste.

Materials and Design Considerations

When it comes to custom precision metal stamping in Foshan, there are several factors to consider when selecting materials and designing products:

1. Material Choice: As mentioned earlier, different materials offer distinct properties that may impact the performance and durability of the final product. For example, aluminum alloys are commonly used in automotive applications because they are lightweight yet strong, while stainless steel is preferred for food processing and medical devices due to its non-corrosive properties. Other materials such as titanium or plastic may be suitable depending on the specific requirements of the project.

2. Design Principles: Effective design principles can help optimize the performance and efficiency of custom precision metal stamping operations. Some common principles include minimizing weight and volume while maintaining strength and stability; ensuring easy accessibility for maintenance and repair; and considering factors such as thermal conductivity or electrical conductivity when designing electronic components.

Benefits and Challenges of Working with Chinese Metal Stamping Manufacturers

There are numerous benefits to working with Chinese metal stamping manufacturers for custom precision metal stamping projects:

1. Cost Savings: Due to their large scale operations and skilled workforce, Chinese metal stamping factories tend to offer lower prices compared to their counterparts abroad. This can result in significant savings for customers who are looking to reduce production costs without compromising quality or performance.

2. Fast Turnaround Times: Many Chinese metal stamping manufacturers have established robust supply chains and logistics systems that allow them to quickly respond to customer demands and deliver orders within tight deadlines. This can be particularly attractive for customers who require rapid prototyping or short lead times for mass production runs.

3. Technical Expertise: Chinese metal stamping factories often possess a wealth of technical expertise in various industries and sectors

Articles related to the knowledge points of this article:

Anhui Customized Household Electrical Appliances: Quality and Customization at Your Service

What are the Five Golds for Whole House Customization?

Custom Metal Fabrication Services for Your Unique Needs

Title: Customizing Hardware Baskets in Zhaoqing: A Comprehensive Guide

Customized Metal Parts Manufacturing: A Tailored Solution for Robust Industrial Solutions