Title: Custom Metal Fabrication Models: Price Guide and Tips

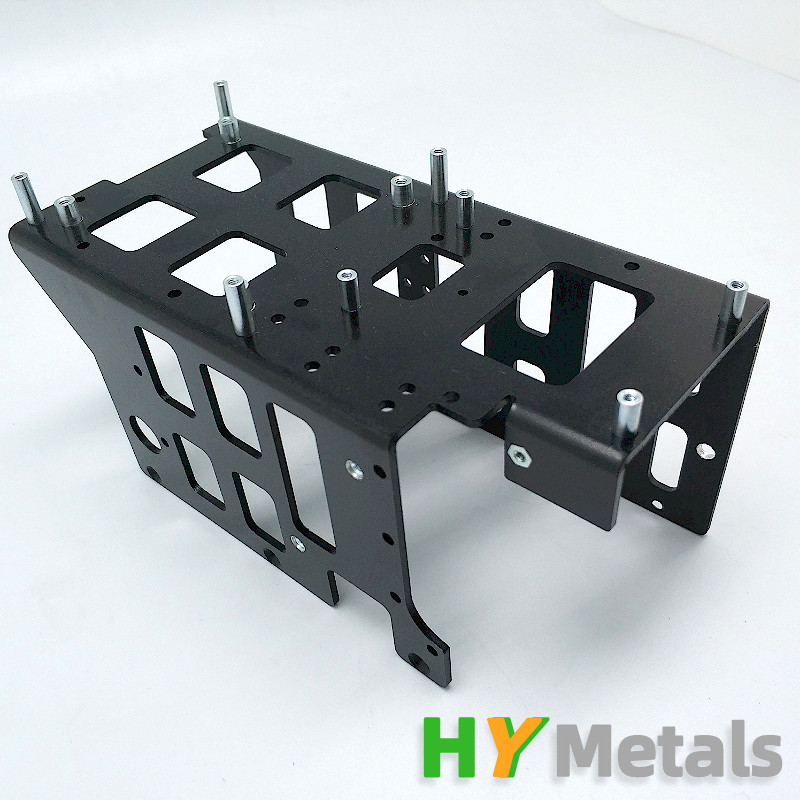

Custom metal fabrication models refer to the creation of bespoke metal products that are tailored to specific requirements and needs. These models can be used in a variety of industries, including aerospace, automotive, construction, and medical devices. The cost of custom metal fabrication models depends on several factors, including material choice, design complexity, size, and production method. It is important to carefully consider these factors when creating a budget for your project and seeking quotes from potential suppliers. When working with a supplier, it is essential to communicate your expectations clearly and ask questions about the process and materials used. By doing so, you can ensure that you receive high-quality results that meet your needs and budget. In conclusion, custom metal fabrication models offer a versatile solution for businesses looking to create unique products. By considering the factors that affect cost and communicating effectively with your supplier, you can achieve the desired results while staying within your budget.

Introduction:

Metal fabrication is an essential part of manufacturing processes that involves the creation of metal parts or components using various techniques such as cutting, bending, welding, and shaping. Custom metal fabrication models are often used in industries such as automotive, aerospace, consumer electronics, and industrial design to create prototypes, test fixtures, and marketing materials. In this article, we will provide you with a detailed guide on custom metal fabrication models, including their prices, factors affecting pricing, and tips for getting the best value for your money.

1、What are Custom Metal Fabrication Models?

Custom metal fabrication models refer to pre-designed metal parts or components that are manufactured according to specific customer requirements. These models can be made from a wide range of metals, including steel, aluminum, copper, titanium, and other alloys. Custom metal fabrication models can be created in various shapes, sizes, and complexity levels, depending on the application and design requirements.

2、Factors Affecting Pricing for Custom Metal Fabrication Models

The cost of custom metal fabrication models can vary significantly depending on several factors, including:

a) Material Choice: The type of metal used in the fabrication process plays a significant role in determining the final cost. Some metals are more expensive than others due to their scarcity, purity, or strength. Additionally, the cost of raw materials may vary based on market fluctuations and supply chain disruptions.

b) Design Complexity: The complexity of the design affects the time and effort required for fabrication. Complex designs may involve intricate shapes, multiple layers of material, or specialized features that increase the manufacturing process's complexity and cost.

c) Size and Dimensional Accuracy: Larger or more complex custom metal fabrication models may require more labor-intensive processes and larger machinery, increasing the overall cost. Additionally, ensuring accurate dimensional tolerances can add additional steps and costs to the manufacturing process.

d) Production Methodology: The production methodology used can also impact the final cost of custom metal fabrication models. For instance, traditional manual fabrication methods may be less efficient but more cost-effective for smaller orders or simple designs. However, automated or computer-controlled fabrication processes may offer faster production times and higher quality control but come with higher costs.

e) Delivery Time: The delivery time required for custom metal fabrication models can affect pricing. Longer lead times may result in higher production costs as manufacturers incur idle machine time and increased inventory costs. Moreover, rush orders or urgent deliveries may require additional fees or surcharges.

3、Tips for Getting the Best Value for Your Money on Custom Metal Fabrication Models

To get the best value for your money when investing in custom metal fabrication models, consider the following tips:

a) Define Your Budget: Before starting the design process, establish a clear budget for your custom metal fabrication project. This will help you identify potential costs overruns and allow you to make informed decisions about design choices and materials.

b) Choose the Right Metal: Select a metal that meets your needs in terms of strength, durability, corrosion resistance, and cost. Consider consulting with a metal supplier or expert to determine which metals are suitable for your project's intended use.

c) Keep Design Simple: Avoid designing overly complex or intricate parts that increase manufacturing time and costs. Simpler designs can be fabricated more efficiently and at a lower cost. Additionally, simplifying the design can help ensure accurate dimensions and reduce the need for costly post-fabrication corrections or modifications.

d) Select an Efficient Manufacturing Process: Choose a manufacturing method that offers the best balance between speed, accuracy, and cost-effectiveness. Consider factors such as automation, labor efficiency, and equipment availability when selecting a production methodology.

e) Request Samples and Quotations: Request samples and quotations from multiple fabricators to compare pricing and quality before making a final decision. This will help you find a reliable manufacturer that offers competitive prices without compromising quality.

f) Negotiate: Don't be afraid to negotiate with fabricators to secure better pricing or discounts on large orders or bulk purchases. Many fabricators are willing to work within certain price ranges to win business.

4、Conclusion

Custom metal fabrication models are a valuable investment for businesses looking to create high-quality prototypes or test fixtures quickly and efficiently. By understanding the factors affecting pricing and following these tips for getting the best value for your money, you can ensure that your custom metal fabrication project stays on track while meeting your financial objectives.

Articles related to the knowledge points of this article:

Title: Customized Metal Fabrication Models in Zhejiang Province: A Comprehensive Guide

Title: Customization of Precise Hardware Stampings in Huzhou

Title: Experience Customization and Excellence in Hardware at Handan Sanitary Ware Furniture Store